358

14 CFR Ch. I (1–1–24 Edition)

§ 25.1431

communication between seated flight

attendants.

[Doc. No. 26003, 58 FR 45229, Aug. 26, 1993, as

amended by Amdt. 25–115, 69 FR 40527, July 2,

2004]

M

ISCELLANEOUS

E

QUIPMENT

§ 25.1431

Electronic equipment.

(a) In showing compliance with

§ 25.1309 (a) and (b) with respect to

radio and electronic equipment and

their installations, critical environ-

mental conditions must be considered.

(b) Radio and electronic equipment

must be supplied with power under the

requirements of § 25.1355(c).

(c) Radio and electronic equipment,

controls, and wiring must be installed

so that operation of any one unit or

system of units will not adversely af-

fect the simultaneous operation of any

other radio or electronic unit, or sys-

tem of units, required by this chapter.

(d) Electronic equipment must be de-

signed and installed such that it does

not cause essential loads to become in-

operative as a result of electrical

power supply transients or transients

from other causes.

[Doc. No. 5066, 29 FR 18291, Dec. 24, 1964, as

amended by Amdt. 25–113, 69 FR 12530, Mar.

16, 2004]

§ 25.1433

Vacuum systems.

There must be means, in addition to

the normal pressure relief, to auto-

matically relieve the pressure in the

discharge lines from the vacuum air

pump when the delivery temperature of

the air becomes unsafe.

[Doc. No. 5066, 29 FR 18291, Dec. 24, 1964, as

amended by Amdt. 25–72, 55 FR 29785, July 20,

1990]

§ 25.1435

Hydraulic systems.

(a)

Element design. Each element of

the hydraulic system must be designed

to:

(1) Withstand the proof pressure

without permanent deformation that

would prevent it from performing its

intended functions, and the ultimate

pressure without rupture. The proof

and ultimate pressures are defined in

terms of the design operating pressure

(DOP) as follows:

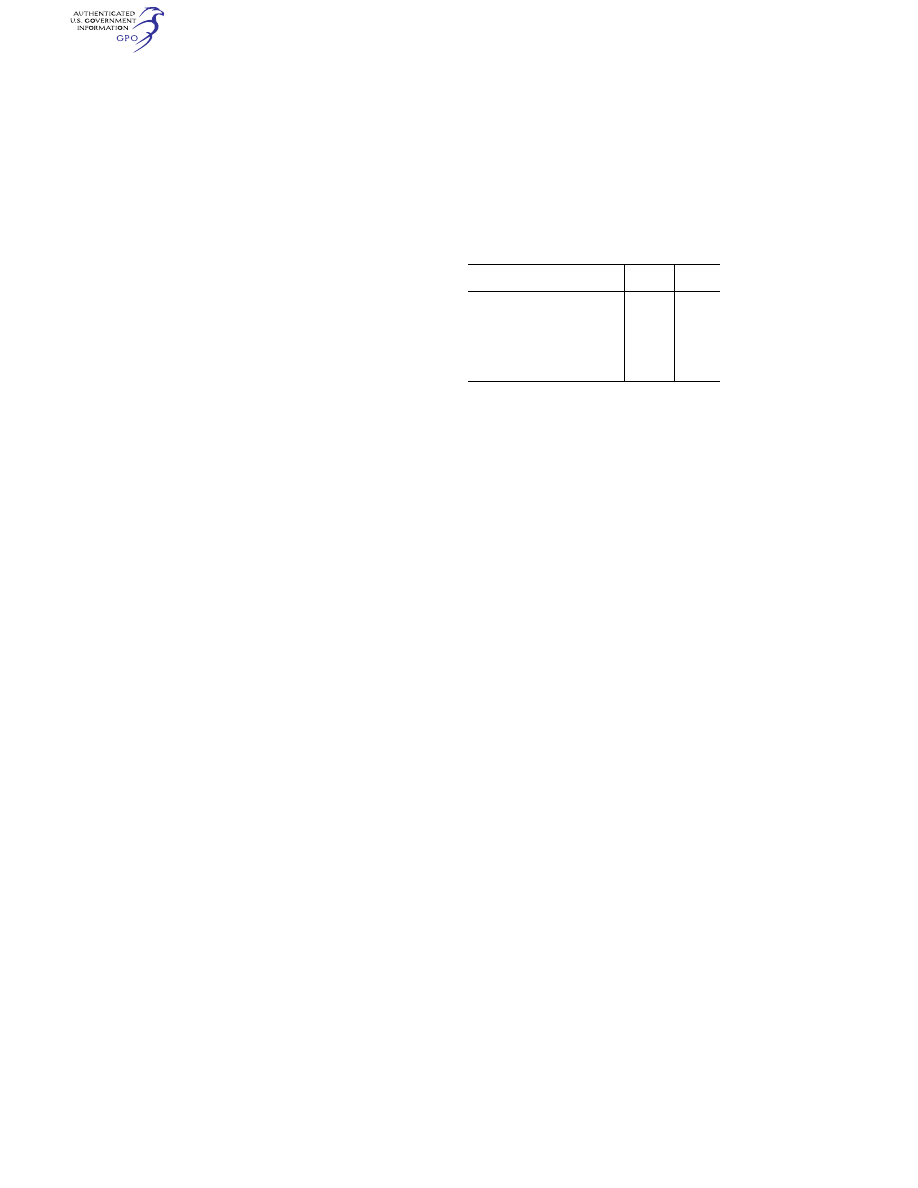

Element

Proof

(xDOP)

Ultimate

(xDOP)

1. Tubes and fittings. .........................

1.5

3.0

2. Pressure vessels containing gas:

High pressure (e.g., accumula-

tors) .........................................

3.0 4.0

Low pressure (e.g., reservoirs) ..

1.5

3.0

3. Hoses ............................................

2.0

4.0

4. All other elements .........................

1.5

2.0

(2) Withstand, without deformation

that would prevent it from performing

its intended function, the design oper-

ating pressure in combination with

limit structural loads that may be im-

posed;

(3) Withstand, without rupture, the

design operating pressure multiplied by

a factor of 1.5 in combination with ulti-

mate structural load that can reason-

ably occur simultaneously;

(4) Withstand the fatigue effects of

all cyclic pressures, including tran-

sients, and associated externally in-

duced loads, taking into account the

consequences of element failure; and

(5) Perform as intended under all en-

vironmental conditions for which the

airplane is certificated.

(b)

System design. Each hydraulic sys-

tem must:

(1) Have means located at a

flightcrew station to indicate appro-

priate system parameters, if

(i) It performs a function necessary

for continued safe flight and landing;

or

(ii) In the event of hydraulic system

malfunction, corrective action by the

crew to ensure continued safe flight

and landing is necessary;

(2) Have means to ensure that system

pressures, including transient pres-

sures and pressures from fluid volu-

metric changes in elements that are

likely to remain closed long enough for

such changes to occur, are within the

design capabilities of each element,

such that they meet the requirements

defined in § 25.1435(a)(1) through (a)(5);

(3) Have means to minimize the re-

lease of harmful or hazardous con-

centrations of hydraulic fluid or vapors

into the crew and passenger compart-

ments during flight;

(4) Meet the applicable requirements

of §§ 25.863, 25.1183, 25.1185, and 25.1189 if

a flammable hydraulic fluid is used;

and

VerDate Sep<11>2014

09:06 Jun 28, 2024

Jkt 262046

PO 00000

Frm 00368

Fmt 8010

Sfmt 8010

Y:\SGML\262046.XXX

262046

jspears on DSK121TN23PROD with CFR