481

Federal Aviation Administration, DOT

§ 26.41

any necessary modification parts will

be made available to affected persons.

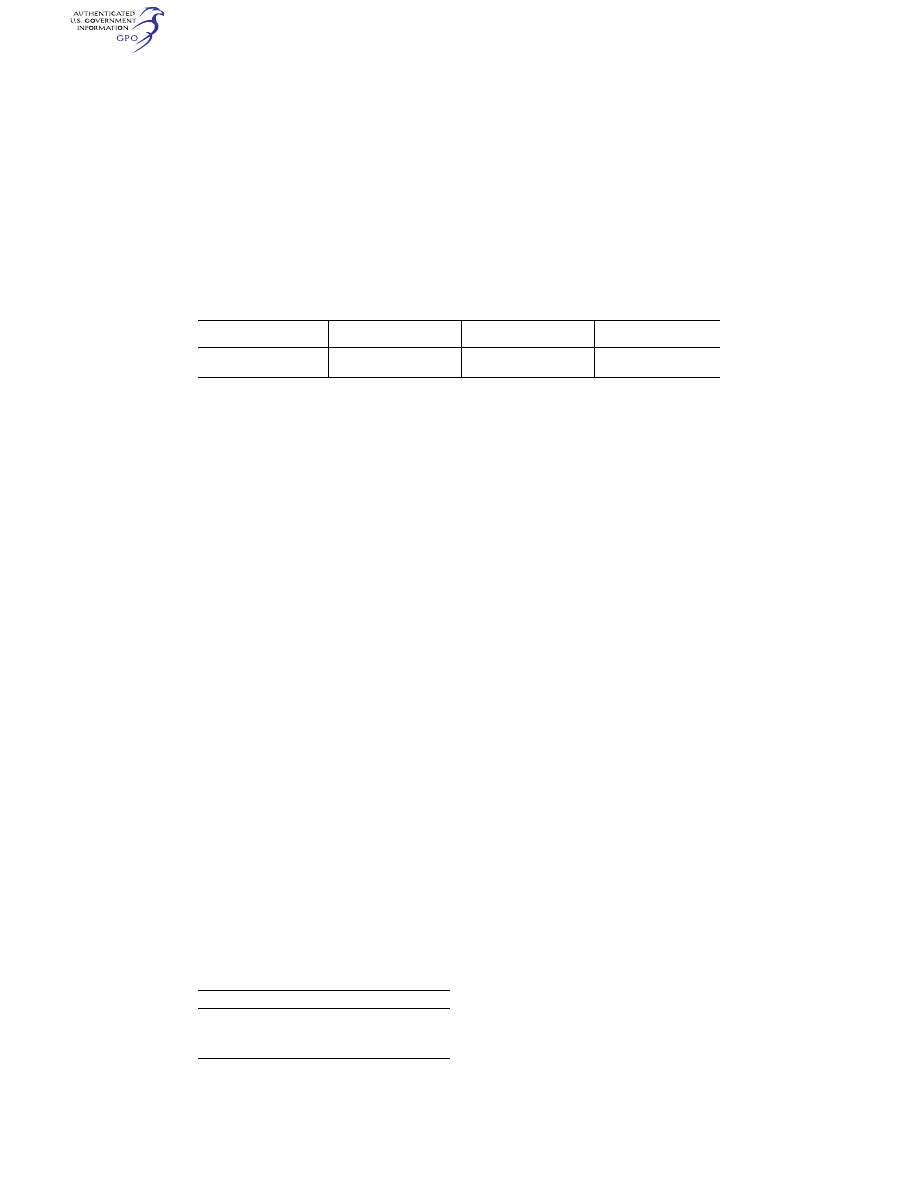

T

ABLE

2—C

OMPLIANCE

P

LANNING

D

ATES

Flammability exposure anal-

ysis plan

Impact assessment plan

Design changes and service

instructions plan

STC and Field Approval Hold-

ers.

March 26, 2009 ......................

February 26, 2011 ..................

August 26, 2011.

(g) Each person subject to this sec-

tion must implement the compliance

plans, or later revisions, as approved

under paragraph (f) of this section.

[Doc. No. FAA–2005–22997, 73 FR 42499, July

21, 2008, as amended by Amdt. 26–3, 74 FR

31619, July 2, 2009; Doc. No. FAA–2018–0119,

Amdt. 26–7, 83 FR 9170, Mar. 5, 2018]

§ 26.37

Pending type certification

projects: Fuel tank flammability.

(a)

Applicability. This section applies

to any new type certificate for a trans-

port category airplane, if the applica-

tion was made before December 26,

2008, and if the certificate was not

issued before December 26, 2008. This

section applies only if the airplane

would have—

(1) A maximum type-certificated pas-

senger capacity of 30 or more, or

(2) A maximum payload capacity of

7,500 pounds or more.

(b) If the application was made on or

after June 6, 2001, the requirements of

14 CFR 25.981 in effect on December 26,

2008, apply.

[Doc. No. FAA–2005–22997, 73 FR 42499, July

21, 2008, as amended by Amdt. 26–3, 74 FR

31619, July 2, 2009]

§ 26.39

Newly produced airplanes: Fuel

tank flammability.

(a)

Applicability: This section applies

to Boeing model airplanes specified in

Table 1 of this section, including pas-

senger and cargo versions of each

model, when application is made for

original certificates of airworthiness or

export airworthiness approvals after

December 27, 2010.

T

ABLE

1

Model—Boeing

747 Series

737 Series

777 Series

767 Series

(b) Any fuel tank meeting all of the

criteria stated in paragraphs (b)(1),

(b)(2) and (b)(3) of this section must

have flammability reduction means

(FRM) or ignition mitigation means

(IMM) that meet the requirements of 14

CFR 25.981 in effect on December 26,

2008.

(1) The fuel tank is Normally

Emptied.

(2) Any portion of the fuel tank is lo-

cated within the fuselage contour.

(3) The fuel tank exceeds a Fleet Av-

erage Flammability Exposure of 7 per-

cent.

(c) All other fuel tanks that exceed

an Fleet Average Flammability Expo-

sure of 7 percent must have an IMM

that meets 14 CFR 25.981(d) in effect on

December 26, 2008, or an FRM that

meets all of the requirements of Appen-

dix M to this part, except instead of

complying with paragraph M25.1 of

that appendix, the Fleet Average Flam-

mability Exposure may not exceed 7

percent.

[Doc. No. FAA–2005–22997, 73 FR 42499, July

21, 2008, as amended by Amdt. 26–3, 74 FR

31619, July 2, 2009]

Subpart E—Aging Airplane Safe-

ty—Damage Tolerance Data

for Repairs and Alterations

S

OURCE

: Docket No. FAA–2005–21693, 72 FR

70505, Dec. 12, 2007, unless otherwise noted.

§ 26.41

Definitions.

Affects (or Affected) means structure

has been physically repaired, altered,

or modified, or the structural loads

acting on the structure have been in-

creased or redistributed.

Baseline structure means structure

that is designed under the original type

certificate or amended type certificate

for that airplane model.

VerDate Sep<11>2014

09:06 Jun 28, 2024

Jkt 262046

PO 00000

Frm 00491

Fmt 8010

Sfmt 8010

Y:\SGML\262046.XXX

262046

jspears on DSK121TN23PROD with CFR

482

14 CFR Ch. I (1–1–24 Edition)

§ 26.43

Damage Tolerance Evaluation (DTE)

means a process that leads to a deter-

mination of maintenance actions nec-

essary to detect or preclude fatigue

cracking that could contribute to a

catastrophic failure. As applied to re-

pairs and alterations, a DTE includes

the evaluation both of the repair or al-

teration and of the fatigue critical

structure affected by the repair or al-

teration.

Damage Tolerance Inspection (DTI)

means the inspection developed as a re-

sult of a DTE. A DTI includes the areas

to be inspected, the inspection method,

the inspection procedures, including

acceptance and rejection criteria, the

threshold, and any repeat intervals as-

sociated with those inspections. The

DTI may specify a time limit when a

repair or alteration needs to be re-

placed or modified. If the DTE con-

cludes that DT-based supplemental

structural inspections are not nec-

essary, the DTI contains a statement

to that effect.

DT data mean DTE documentation

and the DTI.

DTE documentation means data that

identify the evaluated fatigue critical

structure, the basic assumptions ap-

plied in a DTE, and the results of a

DTE.

Fatigue critical structure means air-

plane structure that is susceptible to

fatigue cracking that could contribute

to a catastrophic failure, as determined

in accordance with § 25.571 of this chap-

ter. Fatigue critical structure includes

structure, which, if repaired or altered,

could be susceptible to fatigue crack-

ing and contribute to a catastrophic

failure. Such structure may be part of

the baseline structure or part of an al-

teration.

Implementation schedule consists of

documentation that establishes the

timing for accomplishing the necessary

actions for developing DT data for re-

pairs and alterations, and for incor-

porating those data into an operator’s

continuing airworthiness maintenance

program. The documentation must

identify times when actions must be

taken as specific numbers of airplane

flight hours, flight cycles, or both.

Published repair data mean instruc-

tions for accomplishing repairs, which

are published for general use in struc-

tural repair manuals and service bul-

letins (or equivalent types of docu-

ments).

§ 26.43

Holders of and applicants for

type certificates—Repairs.

(a)

Applicability. Except as specified

in paragraph (g) of this section, this

section applies to transport category,

turbine powered airplane models with a

type certificate issued after January 1,

1958, that as a result of original type

certification or later increase in capac-

ity have—

(1) A maximum type certificated pas-

senger seating capacity of 30 or more;

or

(2) A maximum payload capacity of

7,500 pounds or more.

(b)

List of fatigue critical baseline struc-

ture. For airplanes specified in para-

graph (a) of this section, the holder of

or applicant for a type certificate

must—

(1) Identify fatigue critical baseline

structure for all airplane model vari-

ations and derivatives approved under

the type certificate; and

(2) Develop and submit to the respon-

sible Aircraft Certification Service of-

fice for review and approval, a list of

the structure identified under para-

graph (b)(1) of this section and, upon

approval, make the list available to

persons required to comply with § 26.47

and §§ 121.1109 and 129.109 of this chap-

ter.

(c)

Existing and future published repair

data. For repair data published by a

holder of a type certificate that is cur-

rent as of January 11, 2008 and for all

later published repair data, the holder

of a type certificate must—

(1) Review the repair data and iden-

tify each repair specified in the data

that affects fatigue critical baseline

structure identified under paragraph

(b)(1) of this section;

(2) Perform a DTE and develop the

DTI for each repair identified under

paragraph (c)(1) of this section, unless

previously accomplished;

(3) Submit the DT data to the respon-

sible Aircraft Certification Service of-

fice or its properly authorized des-

ignees for review and approval; and

(4) Upon approval, make the DTI

available to persons required to comply

VerDate Sep<11>2014

09:06 Jun 28, 2024

Jkt 262046

PO 00000

Frm 00492

Fmt 8010

Sfmt 8010

Y:\SGML\262046.XXX

262046

jspears on DSK121TN23PROD with CFR