514

14 CFR Ch. I (1–1–24 Edition)

§ 27.623

(i) The strength requirements of

§ 27.305 at an ultimate load cor-

responding to a casting factor of 1.25;

and

(ii) The deformation requirements of

§ 27.305 at a load of 1.15 times the limit

load.

(d)

Noncritical castings. For each cast-

ing other than those specified in para-

graph (c) of this section, the following

apply:

(1) Except as provided in paragraphs

(d)(2) and (3) of this section, the casting

factors and corresponding inspections

must meet the following table:

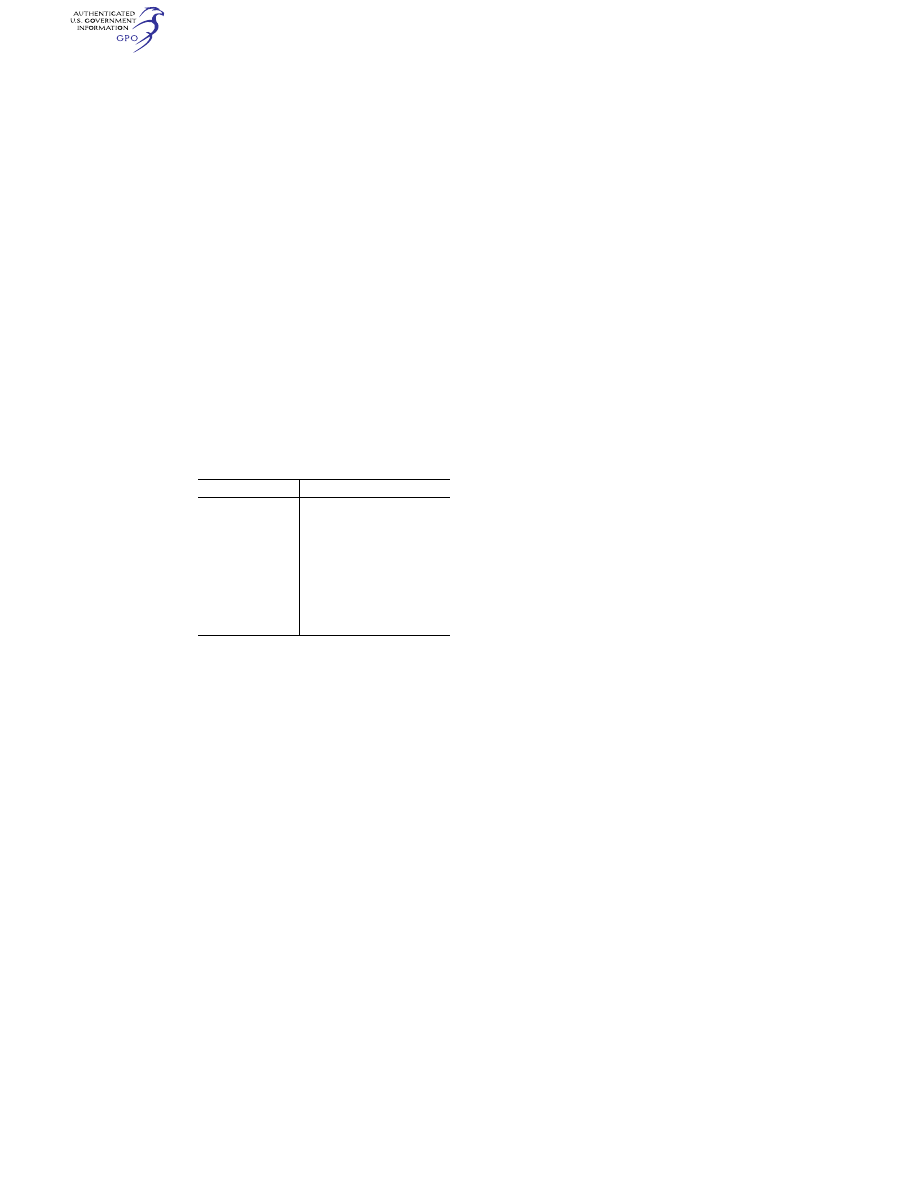

Casting factor

Inspection

2.0 or greater ...............

100 percent visual.

Less than 2.0, greater

than 1.5.

100 percent visual, and magnetic

particle (ferromagnetic materials),

penetrant (nonferromagnetic ma-

terials), or approved equivalent

inspection methods.

1.25 through 1.50 ........

100 percent visual, and magnetic

particle (ferromagnetic materials).

penetrant (nonferromagnetic ma-

terials), and radiographic or ap-

proved equivalent inspection

methods.

(2) The percentage of castings in-

spected by nonvisual methods may be

reduced below that specified in para-

graph (d)(1) of this section when an ap-

proved quality control procedure is es-

tablished.

(3) For castings procured to a speci-

fication that guarantees the mechan-

ical properties of the material in the

casting and provides for demonstration

of these properties by test of coupons

cut from the castings on a sampling

basis—

(i) A casting factor of 1.0 may be

used; and

(ii) The castings must be inspected as

provided in paragraph (d)(1) of this sec-

tion for casting factors of ‘‘1.25 through

1.50’’ and tested under paragraph (c)(2)

of this section.

[Doc. No. 5074, 29 FR 15695, Nov. 24, 1964, as

amended by Amdt. 27–34, 62 FR 46173, Aug. 29,

1997]

§ 27.623

Bearing factors.

(a) Except as provided in paragraph

(b) of this section, each part that has

clearance (free fit), and that is subject

to pounding or vibration, must have a

bearing factor large enough to provide

for the effects of normal relative mo-

tion.

(b) No bearing factor need be used on

a part for which any larger special fac-

tor is prescribed.

§ 27.625

Fitting factors.

For each fitting (part or terminal

used to join one structural member to

another) the following apply:

(a) For each fitting whose strength is

not proven by limit and ultimate load

tests in which actual stress conditions

are simulated in the fitting and sur-

rounding structures, a fitting factor of

at least 1.15 must be applied to each

part of—

(1) The fitting;

(2) The means of attachment; and

(3) The bearing on the joined mem-

bers.

(b) No fitting factor need be used—

(1) For joints made under approved

practices and based on comprehensive

test data (such as continuous joints in

metal plating, welded joints, and scarf

joints in wood); and

(2) With respect to any bearing sur-

face for which a larger special factor is

used.

(c) For each integral fitting, the part

must be treated as a fitting up to the

point at which the section properties

become typical of the member.

(d) Each seat, berth, litter, safety

belt, and harness attachment to the

structure must be shown by analysis,

tests, or both, to be able to withstand

the inertia forces prescribed in

§ 27.561(b)(3) multiplied by a fitting fac-

tor of 1.33.

[Doc. No. 5074, 29 FR 15695, Nov. 24, 1964, as

amended by Amdt. 27–35, 63 FR 43285, Aug. 12,

1998]

§ 27.629

Flutter.

Each aerodynamic surface of the

rotorcraft must be free from flutter

under each appropriate speed and

power condition.

[Doc. No. 5074, 29 FR 15695, Nov. 24, 1964, as

amended by Amdt. 27–26, 55 FR 8000, Mar. 6,

1990]

R

OTORS

§ 27.653

Pressure venting and drain-

age of rotor blades.

(a) For each rotor blade—

VerDate Sep<11>2014

09:06 Jun 28, 2024

Jkt 262046

PO 00000

Frm 00524

Fmt 8010

Sfmt 8010

Y:\SGML\262046.XXX

262046

jspears on DSK121TN23PROD with CFR