691

Federal Aviation Administration, DOT

§ 31.12

(4) From 100 MHz to 8 GHz, use radiated

susceptibility tests at a minimum of 5 V/m.

[Doc. No. FAA–2006–23657, 72 FR 44028, Aug. 6,

2007]

PART 31—AIRWORTHINESS STAND-

ARDS: MANNED FREE BAL-

LOONS

Subpart A—General

Sec.

31.1

Applicability.

Subpart B—Flight Requirements

31.12

Proof of compliance.

31.14

Weight limits.

31.16

Empty weight.

31.17

Performance: Climb.

31.19

Performance: Uncontrolled descent.

31.20

Controllability.

Subpart C—Strength Requirements

31.21

Loads.

31.23

Flight load factor.

31.25

Factor of safety.

31.27

Strength.

Subpart D—Design Construction

31.31

General.

31.33

Materials.

31.35

Fabrication methods.

31.37

Fastenings.

31.39

Protection.

31.41

Inspection provisions.

31.43

Fitting factor.

31.45

Fuel cells.

31.46

Pressurized fuel systems.

31.47

Burners.

31.49

Control systems.

31.51

Ballast.

31.53

Drag rope.

31.55

Deflation means.

31.57

Rip cords.

31.59

Trapeze, basket, or other means pro-

vided for occupants.

31.61

Static discharge.

31.63

Safety belts.

31.65

Position lights.

Subpart E—Equipment

31.71

Function and installation.

Subpart F—Operating Limitations and

Information

31.81

General.

31.82

Instructions for Continued Airworthi-

ness.

31.83

Conspicuity.

31.85

Required basic equipment.

A

PPENDIX

A

TO

P

ART

31—I

NSTRUCTIONS FOR

C

ONTINUED

A

IRWORTHINESS

A

UTHORITY

: 49 U.S.C. 106(g), 40113, 44701–

44702, 44704.

S

OURCE

: Docket No. 1437, 29 FR 8258, July 1,

1964, as amended by Amdt. 31–1, 29 FR 14563,

Oct. 24, 1964, unless otherwise noted.

Subpart A—General

§ 31.1

Applicability.

(a) This part prescribes airworthiness

standards for the issue of type certifi-

cates and changes to those certificates,

for manned free balloons.

(b) Each person who applies under

Part 21 for such a certificate or change

must show compliance with the appli-

cable requirements of this part.

(c) For purposes of this part—

(1) A captive gas balloon is a balloon

that derives its lift from a captive

lighter-than-air gas;

(2) A hot air balloon is a balloon that

derives its lift from heated air;

(3) The envelope is the enclosure in

which the lifting means is contained;

(4) The basket is the container, sus-

pended beneath the envelope, for the

balloon occupants;

(5) The trapeze is a harness or is a

seat consisting of a horizontal bar or

platform suspended beneath the enve-

lope for the balloon occupants; and

(6) The design maximum weight is

the maximum total weight of the bal-

loon, less the lifting gas or air.

[Doc. No. 1437, 29 FR 8258, July 1, 1964, as

amended by Amdt. 31–3, 41 FR 55474, Dec. 20,

1976]

Subpart B—Flight Requirements

§ 31.12

Proof of compliance.

(a) Each requirement of this subpart

must be met at each weight within the

range of loading conditions for which

certification is requested. This must be

shown by—

(1) Tests upon a balloon of the type

for which certification is requested or

by calculations based on, and equal in

accuracy to, the results of testing; and

(2) Systematic investigation of each

weight if compliance cannot be reason-

ably inferred from the weights inves-

tigated.

VerDate Sep<11>2014

09:06 Jun 28, 2024

Jkt 262046

PO 00000

Frm 00701

Fmt 8010

Sfmt 8010

Y:\SGML\262046.XXX

262046

jspears on DSK121TN23PROD with CFR

692

14 CFR Ch. I (1–1–24 Edition)

§ 31.14

(b) Except as provided in § 31.17(b), al-

lowable weight tolerances during flight

testing are + 5 percent and

¥

10 per-

cent.

[Amdt. 31–4, 45 FR 60179, Sept. 11, 1980]

§ 31.14

Weight limits.

(a) The range of weights over which

the balloon may be safely operated

must be established.

(b)

Maximum weight. The maximum

weight is the highest weight at which

compliance with each applicable re-

quirement of this part is shown. The

maximum weight must be established

so that it is not more than—

(1) The highest weight selected by

the applicant;

(2) The design maximum weight

which is the highest weight at which

compliance with each applicable struc-

tural loading condition of this part is

shown; or

(3) The highest weight at which com-

pliance with each applicable flight re-

quirement of this part is shown.

(c) The information established under

paragraphs (a) and (b) of this section

must be made available to the pilot in

accordance with § 31.81.

[Amdt. 31–3, 41 FR 55474, Dec. 20, 1976]

§ 31.16

Empty weight.

The empty weight must be deter-

mined by weighing the balloon with in-

stalled equipment but without lifting

gas or heater fuel.

[Amdt. 31–4, 45 FR 60179, Sept. 11, 1980]

§ 31.17

Performance: Climb.

(a) Each balloon must be capable of

climbing at least 300 feet in the first

minute after takeoff with a steady rate

of climb. Compliance with the require-

ments of this section must be shown at

each altitude and ambient temperature

for which approval is sought.

(b) Compliance with the require-

ments of paragraph (a) of this section

must be shown at the maximum weight

with a weight tolerance of + 5 percent.

[Amdt. 31–4, 45 FR 60179, Sept. 11, 1980]

§ 31.19

Performance: Uncontrolled de-

scent.

(a) The following must be determined

for the most critical uncontrolled de-

scent that can result from any single

failure of the heater assembly, fuel cell

system, gas value system, or maneu-

vering vent system, or from any single

tear in the balloon envelope between

tear stoppers:

(1) The maximum vertical velocity

attained.

(2) The altitude loss from the point of

failure to the point at which maximum

vertical velocity is attained.

(3) The altitude required to achieve

level flight after corrective action is

inititated, with the balloon descending

at the maximum vertical velocity de-

termined in paragraph (a)(1) of this sec-

tion.

(b) Procedures must be established

for landing at the maximum vertical

velocity determined in paragraph (a)(1)

of this section and for arresting that

descent rate in accordance with para-

graph (a)(3) of this section.

[Amdt. 31–4, 45 FR 60179, Sept. 11, 1980]

§ 31.20

Controllability.

The applicant must show that the

balloon is safely controllable and ma-

neuverable during takeoff, ascent, de-

scent, and landing without requiring

exceptional piloting skill.

[Amdt. 31–3, 41 FR 55474, Dec. 20, 1976]

Subpart C—Strength Requirements

§ 31.21

Loads.

Strength requirements are specified

in terms of limit loads, that are the

maximum load to be expected in serv-

ice, and ultimate loads, that are limit

loads multiplied by prescribed factors

of safety. Unless otherwise specified,

all prescribed loads are limit loads.

§ 31.23

Flight load factor.

In determining limit load, the limit

flight load factor must be at least 1.4.

§ 31.25

Factor of safety.

(a) Except as specified in paragraphs

(b) and (c) of this section, the factor of

safety is 1.5.

(b) A factor of safety of at least five

must be used in envelope design. A re-

duced factor of safety of at least two

may be used if it is shown that the se-

lected factor will preclude failure due

to creep or instantaneous rupture from

VerDate Sep<11>2014

09:06 Jun 28, 2024

Jkt 262046

PO 00000

Frm 00702

Fmt 8010

Sfmt 8010

Y:\SGML\262046.XXX

262046

jspears on DSK121TN23PROD with CFR

693

Federal Aviation Administration, DOT

§ 31.41

lack of rip stoppers. The selected fac-

tor must be applied to the more crit-

ical of the maximum operating pres-

sure or envelope stress.

(c) A factor of safety of at least five

must be used in the design of all fi-

brous or non-metallic parts of the rig-

ging and related attachments of the en-

velope to basket, trapeze, or other

means provided for carrying occupants.

The primary attachments of the enve-

lope to the basket, trapeze, or other

means provided for carrying occupants

must be designed so that failure is ex-

tremely remote or so that any single

failure will not jeopardize safety of

flight.

(d) In applying factors of safety, the

effect of temperature, and other oper-

ating characteristics, or both, that

may affect strength of the balloon

must be accounted for.

(e) For design purposes, an occupant

weight of at least 170 pounds must be

assumed.

[Doc. No. 1437, 29 FR 8258, July 1, 1964, as

amended by Amdt. 31–2, 30 FR 3377, Mar. 13,

1965]

§ 31.27

Strength.

(a) The structure must be able to

support limit loads without detri-

mental effect.

(b) The structure must be substan-

tiated by test to be able to withstand

the ultimate loads for at least three

seconds without failure. For the enve-

lope, a test of a representative part is

acceptable, if the part tested is large

enough to include critical seams,

joints, and load attachment points and

members.

(c) An ultimate free-fall drop test

must be made of the basket, trapeze, or

other place provided for occupants. The

test must be made at design maximum

weight on a horizontal surface, with

the basket, trapeze, or other means

provided for carrying occupants, strik-

ing the surface at angles of 0, 15, and 30

degrees. The weight may be distributed

to simulate actual conditions. There

must be no distortion or failure that is

likely to cause serious injury to the oc-

cupants. A drop test height of 36

inches, or a drop test height that pro-

duces, upon impact, a velocity equal to

the maximum vertical velocity deter-

mined in accordance with § 31.19,

whichever is higher, must be used.

[Doc. No. 1437, 29 FR 8258, July 1, 1964, as

amended by Amdt. 31–4, 45 FR 60179, Sept. 11,

1980]

Subpart D—Design Construction

§ 31.31

General.

The suitability of each design detail

or part that bears on safety must be es-

tablished by tests or analysis.

§ 31.33

Materials.

(a) The suitability and durability of

all materials must be established on

the basis of experience or tests. Mate-

rials must conform to approved speci-

fications that will ensure that they

have the strength and other properties

assumed in the design data.

(b) Material strength properties must

be based on enough tests of material

conforming to specifications so as to

establish design values on a statistical

basis.

§ 31.35

Fabrication methods.

The methods of fabrication used

must produce a consistently sound

structure. If a fabrication process re-

quires close control to reach this objec-

tive, the process must be performed in

accordance with an approved process

specification.

§ 31.37

Fastenings.

Only approved bolts, pins, screws,

and rivets may be used in the struc-

ture. Approved locking devices or

methods must be used for all these

bolts, pins, and screws, unless the in-

stallation is shown to be free from vi-

bration. Self-locking nuts may not be

used on bolts that are subject to rota-

tion in service.

§ 31.39

Protection.

Each part of the balloon must be

suitably protected against deteriora-

tion or loss of strength in service due

to weathering, corrosion, or other

causes.

§ 31.41

Inspection provisions.

There must be a means to allow close

examination of each part that require

repeated inspection and adjustment.

VerDate Sep<11>2014

09:06 Jun 28, 2024

Jkt 262046

PO 00000

Frm 00703

Fmt 8010

Sfmt 8010

Y:\SGML\262046.XXX

262046

jspears on DSK121TN23PROD with CFR

694

14 CFR Ch. I (1–1–24 Edition)

§ 31.43

§ 31.43

Fitting factor.

(a) A fitting factor of at least 1.15

must be used in the analysis of each

fitting the strength of which is not

proven by limit and ultimate load tests

in which the actual stress conditions

are simulated in the fitting and sur-

rounding structure. This factor applies

to all parts of the fitting, the means of

attachment, and the bearing on the

members joined.

(b) Each part with an integral fitting

must be treated as a fitting up to the

point where the section properties be-

come typical of the member.

(c) The fitting factor need not be

used if the joint design is made in ac-

cordance with approved practices and

is based on comprehensive test data.

§ 31.45

Fuel cells.

If fuel cells are used, the fuel cells,

their attachments, and related sup-

porting structure must be shown by

tests to be capable of withstanding,

without detrimental distortion or fail-

ure, any inertia loads to which the in-

stallation may be subjected, including

the drop tests prescribed in § 31.27(c). In

the tests, the fuel cells must be loaded

to the weight and pressure equivalent

to the full fuel quantity condition.

[Amdt. 31–3, 41 FR 55474, Dec. 20, 1976]

§ 31.46

Pressurized fuel systems.

For pressurized fuel systems, each

element and its connecting fittings and

lines must be tested to an ultimate

pressure of at least twice the maximum

pressure to which the system will be

subjected in normal operation. No part

of the system may fail or malfunction

during the test. The test configuration

must be representative of the normal

fuel system installation and balloon

configuration.

[Amdt. 31–3, 41 FR 55474, Dec. 20, 1976]

§ 31.47

Burners.

(a) If a burner is used to provide the

lifting means, the system must be de-

signed and installed so as not to create

a fire hazard.

(b) There must be shielding to pro-

tect parts adjacent to the burner

flame, and the occupants, from heat ef-

fects.

(c) There must be controls, instru-

ments, or other equipment essential to

the safe control and operation of the

heater. They must be shown to be able

to perform their intended functions

during normal and emergency oper-

ation.

(d) The burner system (including the

burner unit, controls, fuel lines, fuel

cells, regulators, control valves, and

other related elements) must be sub-

stantiated by an endurance test of at

least 40 hours. Each element of the sys-

tem must be installed and tested to

simulate actual balloon installation

and use.

(1) The test program for the main

blast valve operation of the burner

must include:

(i) Five hours at the maximum fuel

pressure for which approval is sought,

with a burn time for each one minute

cycle of three to ten seconds. The burn

time must be established so that each

burner is subjected to the maximum

thermal shock for temperature affected

elements;

(ii) Seven and one-half hours at an

intermediate fuel pressure, with a burn

time for each one minute cycle of three

to ten seconds. An intermediate fuel

pressure is 40 to 60 percent of the range

between the maximum fuel pressure

referenced in paragraph (d)(1)(i) of this

section and minimum fuel pressure ref-

erenced in paragraph (d)(1)(iii);

(iii) Six hours and fifteen minutes at

the minimum fuel pressure for which

approval is sought, with a burn time

for each one minute cycle of three to

ten seconds;

(iv) Fifteen minutes of operation on

vapor, with a burn time for each one

minute cycle of at least 30 seconds; and

(v) Fifteen hours of normal flight op-

eration.

(2) The test program for the sec-

ondary or backup operation of the

burner must include six hours of oper-

ation with a burn time for each five

minute cycle of one minute at an inter-

mediate fuel pressure.

(e) The test must also include at

least three flameouts and restarts.

VerDate Sep<11>2014

09:06 Jun 28, 2024

Jkt 262046

PO 00000

Frm 00704

Fmt 8010

Sfmt 8010

Y:\SGML\262046.XXX

262046

jspears on DSK121TN23PROD with CFR

695

Federal Aviation Administration, DOT

§ 31.61

(f) Each element of the system must

be serviceable at the end of the test.

[Doc. No. 1437, 29 FR 8258, July 1, 1964, as

amended by Amdt. 31–2, 30 FR 3377, Mar. 13,

1965; Amdt. 31–7, 61 FR 18223, Apr. 24, 1996; 61

FR 20877, May 8, 1996]

§ 31.49

Control systems.

(a) Each control must operate easily,

smoothly, and positively enough to

allow proper performance of its func-

tions. Controls must be arranged and

identified to provide for convenience of

operation and to prevent the possi-

bility of confusion and subsequent in-

advertent operation.

(b) Each control system and oper-

ating device must be designed and in-

stalled in a manner that will prevent

jamming, chafing, or interference from

passengers, cargo, or loose objects. Pre-

caution must be taken to prevent for-

eign objects from jamming the con-

trols. The elements of the control sys-

tem must have design features or must

be distinctly and permanently marked

to minimize the possibility of incorrect

assembly that could result in malfunc-

tioning of the control system.

(c) Each balloon using a captive gas

as the lifting means must have an

automatic valve or appendix that is

able to release gas automatically at

the rate of at least three percent of the

total volume per minute when the bal-

loon is at its maximum operating pres-

sure.

(d) Each hot air balloon must have a

means to allow the controlled release

of hot air during flight.

(e) Each hot air balloon must have a

means to indicate the maximum enve-

lope skin temperatures occurring dur-

ing operation. The indicator must be

readily visible to the pilot and marked

to indicate the limiting safe tempera-

ture of the envelope material. If the

markings are on the cover glass of the

instrument, there must be provisions

to maintain the correct alignment of

the glass cover with the face of the

dial.

[Doc. No. 1437, 29 FR 8258, July 1, 1964, as

amended by Amdt. 31–2, 30 FR 3377, Mar. 13,

1965]

§ 31.51

Ballast.

Each captive gas balloon must have a

means for the safe storage and con-

trolled release of ballast. The ballast

must consist of material that, if re-

leased during flight, is not hazardous

to persons on the ground.

§ 31.53

Drag rope.

If a drag rope is used, the end that is

released overboard must be stiffened to

preclude the probability of the rope be-

coming entangled with trees, wires, or

other objects on the ground.

§ 31.55

Deflation means.

There must be a means to allow

emergency deflation of the envelope so

as to allow a safe emergency landing. If

a system other than a manual system

is used, the reliability of the system

used must be substantiated.

[Amdt. 31–2, 30 FR 3377, Mar. 13, 1965]

§ 31.57

Rip cords.

(a) If a rip cord is used for emergency

deflation, it must be designed and in-

stalled to preclude entanglement.

(b) The force required to operate the

rip cord may not be less than 25, or

more than 75, pounds.

(c) The end of the rip cord to be oper-

ated by the pilot must be colored red.

(d) The rip cord must be long enough

to allow an increase of at least 10 per-

cent in the vertical dimension of the

envelope.

§ 31.59

Trapeze, basket, or other

means provided for occupants.

(a) The trapeze, basket, or other

means provided for carrying occupants

may not rotate independently of the

envelope.

(b) Each projecting object on the tra-

peze, basket, or other means provided

for carrying occupants, that could

cause injury to the occupants, must be

padded.

§ 31.61

Static discharge.

Unless shown not to be necessary for

safety, there must be appropriate bond-

ing means in the design of each balloon

using flammable gas as a lifting means

to ensure that the effects of static dis-

charges will not create a hazard.

[Amdt. 31–2, 30 FR 3377, Mar. 13, 1965]

VerDate Sep<11>2014

09:06 Jun 28, 2024

Jkt 262046

PO 00000

Frm 00705

Fmt 8010

Sfmt 8010

Y:\SGML\262046.XXX

262046

jspears on DSK121TN23PROD with CFR

696

14 CFR Ch. I (1–1–24 Edition)

§ 31.63

§ 31.63

Safety belts.

(a) There must be a safety belt, har-

ness, or other restraining means for

each occupant, unless the Adminis-

trator finds it unnecessary. If installed,

the belt, harness, or other restraining

means and its supporting structure

must meet the strength requirements

of subpart C of this part.

(b) This section does not apply to bal-

loons that incorporate a basket or gon-

dola.

[Amdt. 31–2, 30 FR 3377, Mar. 13, 1965, as

amended by Amdt. 31–3, 41 FR 55474, Dec. 20,

1976]

§ 31.65

Position lights.

(a) If position lights are installed,

there must be one steady aviation

white position light and one flashing

aviation red (or flashing aviation

white) position light with an effective

flash frequency of at least 40, but not

more than 100, cycles per minute.

(b) Each light must provide 360

°

hori-

zontal coverage at the intensities pre-

scribed in this paragraph. The fol-

lowing light intensities must be deter-

mined with the light source operating

at a steady state and with all light cov-

ers and color filters in place and at the

manufacturer’s rated minimum volt-

age. For the flashing aviation red light,

the measured values must be adjusted

to correspond to a red filter tempera-

ture of at least 130

°

F:

(1) The intensities in the horizontal

plane passing through the light unit

must equal or exceed the following val-

ues:

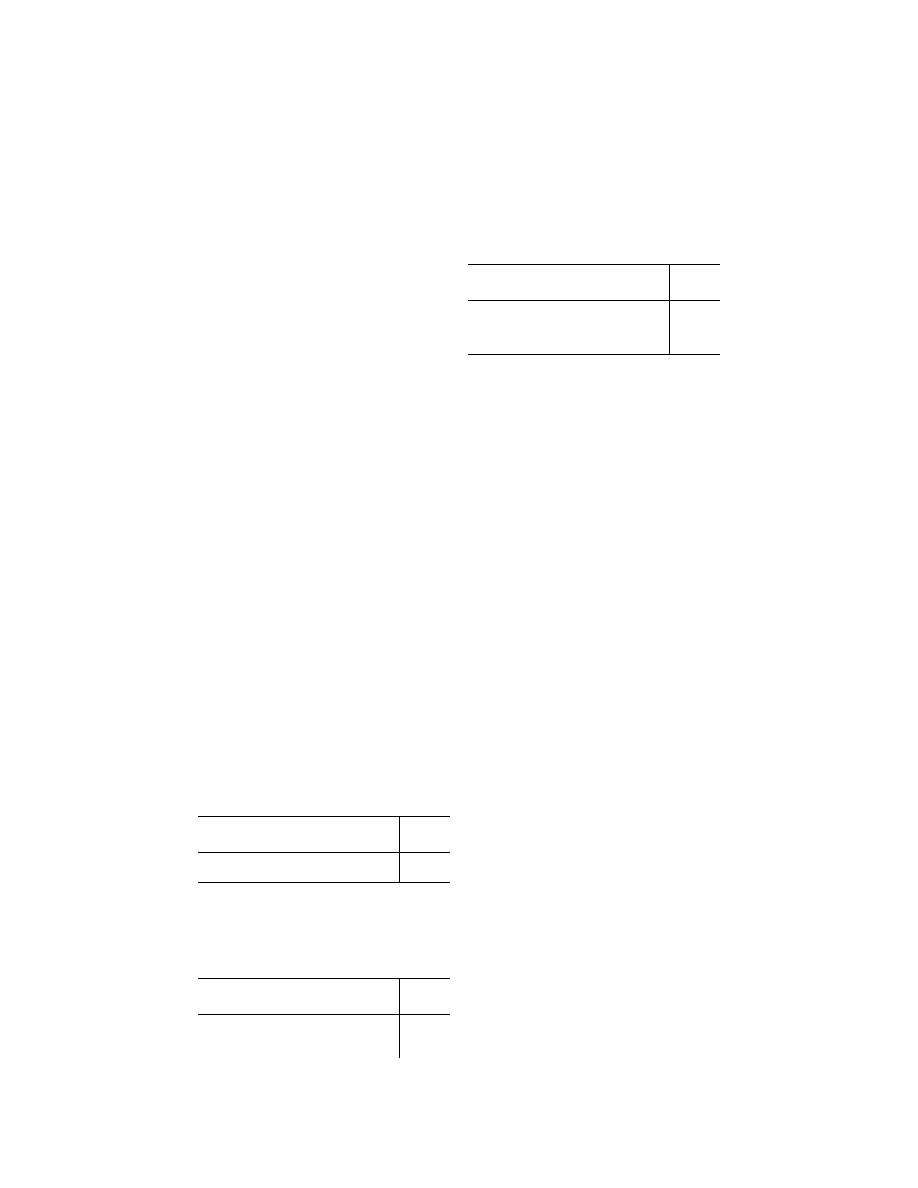

Position light

Minimum

intensity

(candles)

Steady white ........................................................

20

Flashing red or white ...........................................

40

(2) The intensities in vertical planes

must equal or exceed the following val-

ues. An intensity of one unit cor-

responds to the applicable horizontal

plane intensity specified in paragraph

(b)(1) of this section.

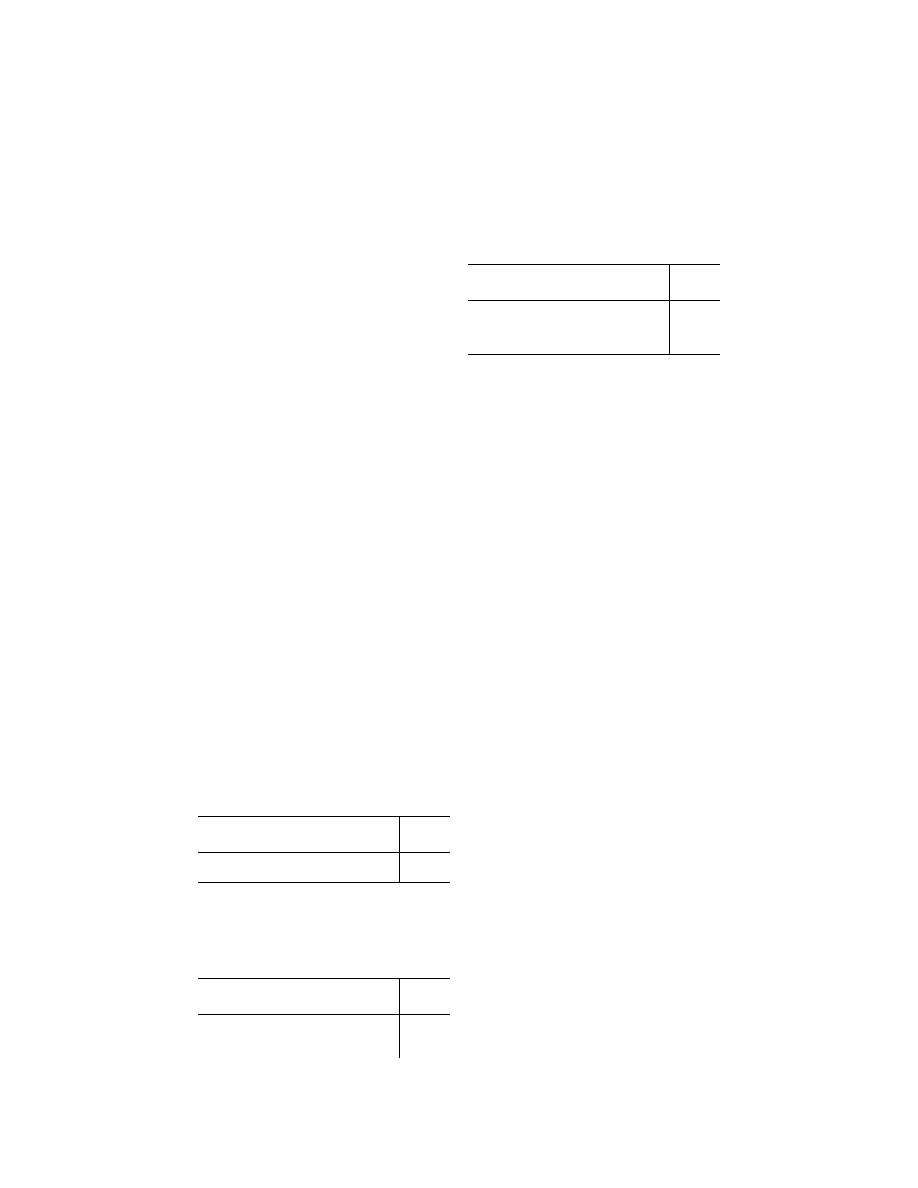

Angles above and below the horizontal in any

vertical plane (degrees)

Minimum

intensity

(units)

0 ...........................................................................

1.00

0 to 5 ...................................................................

0.90

5 to 10 .................................................................

0.80

10 to 15 ...............................................................

0.70

Angles above and below the horizontal in any

vertical plane (degrees)

Minimum

intensity

(units)

15 to 20 ...............................................................

0.50

20 to 30 ...............................................................

0.30

30 to 40 ...............................................................

0.10

40 to 60 ...............................................................

0.05

(c) The steady white light must be lo-

cated not more than 20 feet below the

basket, trapeze, or other means for car-

rying occupants. The flashing red or

white light must be located not less

than 7, nor more than 10, feet below the

steady white light.

(d) There must be a means to retract

and store the lights.

(e) Each position light color must

have the applicable International Com-

mission on Illumination chromaticity

coordinates as follows:

(1)

Aviation red—

y is not greater than 0.335; and z is not great-

er than 0.002.

(2)

Aviation white—

x is not less than 0.300 and not greater than

0.540;

y is not less than x

¥

0.040 or

y

o

¥

0.010, which-

ever is the smaller; and

y is not greater than x + 0.020 nor

0.636

¥

0.0400

x;

Where

y

o

is the

y coordinate of the Planckian

radiator for the value of

x considered.

[Doc. No. 1437, 29 FR 8258, July 1, 1964, as

amended by Amdt. 31–1, 29 FR 14563, Oct. 24,

1964; Amdt. 31–4, 45 FR 60179, Sept. 11, 1980]

Subpart E—Equipment

§ 31.71

Function and installation.

(a) Each item of installed equipment

must—

(1) Be of a kind and design appro-

priate to its intended function;

(2) Be permanently and legibly

marked or, if the item is too small to

mark, tagged as to its identification,

function, or operating limitations, or

any applicable combination of those

factors;

(3) Be installed according to limita-

tions specified for that equipment; and

(4) Function properly when installed.

(b) No item of installed equipment,

when performing its function, may af-

fect the function of any other equip-

ment so as to create an unsafe condi-

tion.

VerDate Sep<11>2014

09:06 Jun 28, 2024

Jkt 262046

PO 00000

Frm 00706

Fmt 8010

Sfmt 8010

Y:\SGML\262046.XXX

262046

jspears on DSK121TN23PROD with CFR

697

Federal Aviation Administration, DOT

Pt. 31, App. A

(c) The equipment, systems, and in-

stallations must be designed to prevent

hazards to the balloon in the event of a

probable malfunction or failure.

[Amdt. 31–4, 45 FR 60180, Sept. 11, 1980]

Subpart F—Operating Limitations

and Information

§ 31.81

General.

(a) The following information must

be established:

(1) Each operating limitation, includ-

ing the maximum weight determined

under § 31.14.

(2) The normal and emergency proce-

dures.

(3) Other information necessary for

safe operation, including—

(i) The empty weight determined

under § 31.16;

(ii) The rate of climb determined

under § 31.17, and the procedures and

conditions used to determine perform-

ance;

(iii) The maximum vertical velocity,

the altitude drop required to attain

that velocity, and altitude drop re-

quired to recover from a descent at

that velocity, determined under § 31.19,

and the procedures and conditions used

to determine performance; and

(iv) Pertinent information peculiar

to the balloon’s operating characteris-

tics.

(b) The information established in

compliance with paragraph (a) of this

section must be furnished by means

of—

(1) A Balloon Flight Manual; or

(2) A placard on the balloon that is

clearly visible to the pilot.

[Amdt. 31–4, 45 FR 60180, Sept. 11, 1980]

§ 31.82

Instructions for Continued Air-

worthiness.

The applicant must prepare Instruc-

tions for Continued Airworthiness in

accordance with appendix A to this

part that are acceptable to the Admin-

istrator. The instructions may be in-

complete at type certification if a pro-

gram exists to ensure their completion

prior to delivery of the first balloon or

issuance of a standard certificate of

airworthiness, whichever occurs later.

[Amdt. 31–4, 45 FR 60180, Sept. 11, 1980]

§ 31.83

Conspicuity.

The exterior surface of the envelope

must be of a contrasting color or colors

so that it will be conspicuous during

operation. However, multicolored ban-

ners or streamers are acceptable if it

can be shown that they are large

enough, and there are enough of them

of contrasting color, to make the bal-

loon conspicuous during flight.

§ 31.85

Required basic equipment.

In addition to any equipment re-

quired by this subchapter for a specific

kind of operation, the following equip-

ment is required:

(a) For all balloons:

(1) [Reserved]

(2) An altimeter.

(3) A rate of climb indicator.

(b) For hot air balloons:

(1) A fuel quantity gauge. If fuel cells

are used, means must be incorporated

to indicate to the crew the quantity of

fuel in each cell during flight. The

means must be calibrated in appro-

priate units or in percent of fuel cell

capacity.

(2) An envelope temperature indi-

cator.

(c) For captive gas balloons, a com-

pass.

[Amdt. 31–2, 30 FR 3377, Mar. 13, 1965, as

amended by Amdt. 31–3, 41 FR 55474, Dec. 20,

1976; Amdt. 31–4, 45 FR 60180, Sept. 11, 1980]

A

PPENDIX

A

TO

P

ART

31—I

NSTRUCTIONS

FOR

C

ONTINUED

A

IRWORTHINESS

A

31.1

GENERAL

(a) This appendix specifies requirements

for the preparation of Instructions for Con-

tinued Airworthiness as required by § 31.82.

(b) The Instructions for Continued Air-

worthiness for each balloon must include the

Instructions for Continued Airworthiness for

all balloon parts required by this chapter

and any required information relating to the

interface of those parts with the balloon. If

Instructions for Continued Airworthiness are

not supplied by the part manufacturer for a

balloon part, the Instructions for Continued

Airworthiness for the balloon must include

the information essential to the continued

airworthiness of the balloon.

(c) The applicant must submit to the FAA

a program to show how changes to the In-

structions for Continued Airworthiness made

VerDate Sep<11>2014

09:06 Jun 28, 2024

Jkt 262046

PO 00000

Frm 00707

Fmt 8010

Sfmt 8002

Y:\SGML\262046.XXX

262046

jspears on DSK121TN23PROD with CFR

698

14 CFR Ch. I (1–1–24 Edition)

Pt. 33

by the applicant or by the manufacturers of

balloon parts will be distributed.

A

31.2

FORMAT

(a) The Instructions for Continued Air-

worthiness must be in the form of a manual

or manuals as appropriate for the quantity

of data to be provided.

(b) The format of the manual or manuals

must provide for a practical arrangement.

A

31.3

CONTENT

The contents of the manual or manuals

must be prepared in the English language.

The Instructions for Continued Airworthi-

ness must contain the following information:

(a) Introduction information that includes

an explanation of the balloon’s features and

data to the extent necessary for mainte-

nance or preventive maintenance.

(b) A description of the balloon and its sys-

tems and installations.

(c) Basic control and operation informa-

tion for the balloon and its components and

systems.

(d) Servicing information that covers de-

tails regarding servicing of balloon compo-

nents, including burner nozzles, fuel tanks,

and valves during operations.

(e) Maintenance information for each part

of the balloon and its envelope, controls, rig-

ging, basket structure, fuel systems, instru-

ments, and heater assembly that provides

the recommended periods at which they

should be cleaned, adjusted, tested, and lu-

bricated, the applicable wear tolerances, and

the degree of work recommended at these pe-

riods. However, the applicant may refer to

an accessory, instrument, or equipment

manufacturer as the source of this informa-

tion if the applicant shows that the item has

an exceptionally high degree of complexity

requiring specialized maintenance tech-

niques, test equipment, or expertise. The rec-

ommended overhaul periods and necessary

cross references to the Airworthiness Limi-

tations section of the manual must also be

included. In addition, the applicant must in-

clude an inspection program that includes

the frequency and extent of the inspections

necessary to provide for the continued air-

worthiness of the balloon.

(f) Troubleshooting information describing

probable malfunctions, how to recognize

those malfunctions, and the remedial action

for those malfunctions.

(g) Details of what, and how, to inspect

after a hard landing.

(h) Instructions for storage preparation in-

cluding any storage limits.

(i) Instructions for repair on the balloon

envelope and its basket or trapeze.

A

31.4

AIRWORTHINESS LIMITATIONS SECTION

The Instructions for Continued Airworthi-

ness must contain a section titled Airworthi-

ness Limitations that is segregated and

clearly distinguishable from the rest of the

document. This section must set forth each

mandatory replacement time, structural in-

spection interval, and related structural in-

spection procedure, including envelope struc-

tural integrity, required for type certifi-

cation. If the Instructions for Continued Air-

worthiness consist of multiple documents,

the section required by this paragraph must

be included in the principal manual. This

section must contain a legible statement in

a prominent location that reads: ‘‘The Air-

worthiness Limitations section is FAA ap-

proved and specifies maintenance required

under §§ 43.16 and 91.403 of the Federal Avia-

tion Regulations.’’

[Amdt. 31–4, 45 FR 60180, Sept. 11, 1980, as

amended by Amdt. 31–5, 54 FR 34330, Aug. 18,

1989]

PART 33—AIRWORTHINESS

STANDARDS: AIRCRAFT ENGINES

Subpart A—General

Sec.

33.1

Applicability.

33.3

General.

33.4

Instructions for Continued Airworthi-

ness.

33.5

Instruction manual for installing and

operating the engine.

33.7

Engine ratings and operating limita-

tions.

33.8

Selection of engine power and thrust

ratings.

Subpart B—Design and Construction;

General

33.11

Applicability.

33.13

[Reserved]

33.15

Materials.

33.17

Fire protection.

33.19

Durability.

33.21

Engine cooling.

33.23

Engine mounting attachments and

structure.

33.25

Accessory attachments.

33.27

Turbine, compressor, fan, and turbo-

supercharger rotor overspeed.

33.28

Engine control systems.

33.29

Instrument connection.

Subpart C—Design and Construction;

Reciprocating Aircraft Engines

33.31

Applicability.

33.33

Vibration.

33.34

Turbocharger rotors.

33.35

Fuel and induction system.

33.37

Ignition system.

33.39

Lubrication system.

VerDate Sep<11>2014

09:06 Jun 28, 2024

Jkt 262046

PO 00000

Frm 00708

Fmt 8010

Sfmt 8010

Y:\SGML\262046.XXX

262046

jspears on DSK121TN23PROD with CFR