714

14 CFR Ch. I (1–1–24 Edition)

§ 33.68

not be manipulated while the fuel con-

trol device is mounted on the engine

must be secured by a locking device

and sealed, or otherwise be inacces-

sible. All other fuel control adjusting

means must be accessible and marked

to indicate the function of the adjust-

ment unless the function is obvious.

(b) There must be a fuel strainer or

filter between the engine fuel inlet

opening and the inlet of either the fuel

metering device or the engine-driven

positive displacement pump whichever

is nearer the engine fuel inlet. In addi-

tion, the following provisions apply to

each strainer or filter required by this

paragraph (b):

(1) It must be accessible for draining

and cleaning and must incorporate a

screen or element that is easily remov-

able.

(2) It must have a sediment trap and

drain except that it need not have a

drain if the strainer or filter is easily

removable for drain purposes.

(3) It must be mounted so that its

weight is not supported by the con-

necting lines or by the inlet or outlet

connections of the strainer or filter,

unless adequate strength margins

under all loading conditions are pro-

vided in the lines and connections.

(4) It must have the type and degree

of fuel filtering specified as necessary

for protection of the engine fuel system

against foreign particles in the fuel.

The applicant must show:

(i) That foreign particles passing

through the specified filtering means

do not impair the engine fuel system

functioning; and

(ii) That the fuel system is capable of

sustained operation throughout its

flow and pressure range with the fuel

initially saturated with water at 80

°

F

(27

°

C) and having 0.025 fluid ounces per

gallon (0.20 milliliters per liter) of free

water added and cooled to the most

critical condition for icing likely to be

encountered in operation. However,

this requirement may be met by dem-

onstrating the effectiveness of speci-

fied approved fuel anti-icing additives,

or that the fuel system incorporates a

fuel heater which maintains the fuel

temperature at the fuel strainer or fuel

inlet above 32

°

F (0

°

C) under the most

critical conditions.

(5) The applicant must demonstrate

that the filtering means has the capac-

ity (with respect to engine operating

limitations) to ensure that the engine

will continue to operate within ap-

proved limits, with fuel contaminated

to the maximum degree of particle size

and density likely to be encountered in

service. Operation under these condi-

tions must be demonstrated for a pe-

riod acceptable to the Administrator,

beginning when indication of impend-

ing filter blockage is first given by ei-

ther:

(i) Existing engine instrumentation;

or

(ii) Additional means incorporated

into the engine fuel system.

(6) Any strainer or filter bypass must

be designed and constructed so that the

release of collected contaminants is

minimized by appropriate location of

the bypass to ensure that collected

contaminants are not in the bypass

flow path.

(c) If provided as part of the engine,

the applicant must show for each fluid

injection (other than fuel) system and

its controls that the flow of the in-

jected fluid is adequately controlled.

[Amdt. 33–6, 39 FR 35466, Oct. 1, 1974, as

amended by Amdt. 33–10, 49 FR 6851, Feb. 23,

1984; Amdt. 33–18, 61 FR 31328, June 19, 1996;

Amdt. 33–25, 73 FR 48123, Aug. 18, 2008; Amdt.

33–26, 73 FR 48285, Aug. 19, 2008]

§ 33.68

Induction system icing.

Each engine, with all icing protec-

tion systems operating, must:

(a) Operate throughout its flight

power range, including the minimum

descent idle rotor speeds achievable in

flight, in the icing conditions defined

for turbojet, turbofan, and turboprop

engines in Appendices C and O of part

25 of this chapter, and Appendix D of

this part, and for turboshaft engines in

Appendix C of part 29 of this chapter,

without the accumulation of ice on the

engine components that:

(1) Adversely affects engine operation

or that causes an unacceptable perma-

nent loss of power or thrust or unac-

ceptable increase in engine operating

temperature; or

(2) Results in unacceptable tem-

porary power loss or engine damage; or

(3) Causes a stall, surge, or flameout

or loss of engine controllability. The

VerDate Sep<11>2014

09:06 Jun 28, 2024

Jkt 262046

PO 00000

Frm 00724

Fmt 8010

Sfmt 8010

Y:\SGML\262046.XXX

262046

jspears on DSK121TN23PROD with CFR

715

Federal Aviation Administration, DOT

§ 33.68

applicant must account for in-flight

ram effects in any critical point anal-

ysis or test demonstration of these

flight conditions.

(b) Operate throughout its flight

power range, including minimum de-

scent idle rotor speeds achievable in

flight, in the icing conditions defined

for turbojet, turbofan, and turboprop

engines in Appendices C and O of part

25 of this chapter, and for turboshaft

engines in Appendix C of part 29 of this

chapter. In addition:

(1) It must be shown through Critical

Point Analysis (CPA) that the com-

plete ice envelope has been analyzed,

and that the most critical points must

be demonstrated by engine test, anal-

ysis, or a combination of the two to op-

erate acceptably. Extended flight in

critical flight conditions such as hold,

descent, approach, climb, and cruise,

must be addressed, for the ice condi-

tions defined in these appendices.

(2) It must be shown by engine test,

analysis, or a combination of the two

that the engine can operate acceptably

for the following durations:

(i) At engine powers that can sustain

level flight: A duration that achieves

repetitive, stabilized operation for tur-

bojet, turbofan, and turboprop engines

in the icing conditions defined in Ap-

pendices C and O of part 25 of this

chapter, and for turboshaft engines in

the icing conditions defined in Appen-

dix C of part 29 of this chapter.

(ii) At engine power below that which

can sustain level flight:

(A) Demonstration in altitude flight

simulation test facility: A duration of

10 minutes consistent with a simulated

flight descent of 10,000 ft (3 km) in alti-

tude while operating in Continuous

Maximum icing conditions defined in

Appendix C of part 25 of this chapter

for turbojet, turbofan, and turboprop

engines, and for turboshaft engines in

the icing conditions defined in Appen-

dix C of part 29 of this chapter, plus 40

percent liquid water content margin,

at the critical level of airspeed and air

temperature; or

(B) Demonstration in ground test fa-

cility: A duration of 3 cycles of alter-

nating icing exposure corresponding to

the liquid water content levels and

standard cloud lengths starting in

Intermittent Maximum and then in

Continuous Maximum icing conditions

defined in Appendix C of part 25 of this

chapter for turbojet, turbofan, and tur-

boprop engines, and for turboshaft en-

gines in the icing conditions defined in

Appendix C of part 29 of this chapter,

at the critical level of air temperature.

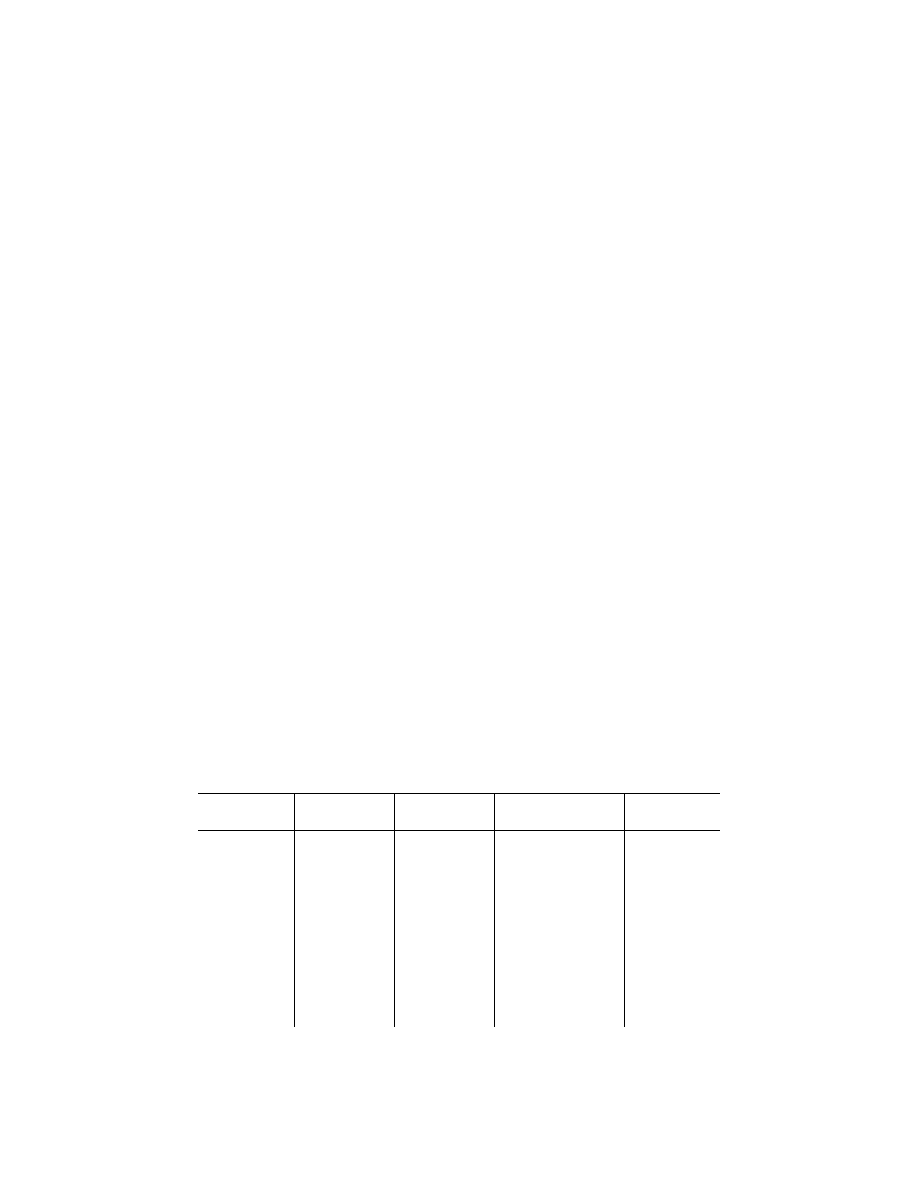

(c) In addition to complying with

paragraph (b) of this section, the fol-

lowing conditions shown in Table 1 of

this section unless replaced by similar

CPA test conditions that are more crit-

ical or produce an equivalent level of

severity, must be demonstrated by an

engine test:

T

ABLE

1—C

ONDITIONS

T

HAT

M

UST

B

E

D

EMONSTRATED BY AN

E

NGINE

T

EST

Condition

Total air temperature

Supercooled water

concentrations

(minimum)

Median volume drop diameter

Duration

1. Glaze ice condi-

tions.

21 to 25

°

F (

¥

6 to

¥

4

°

C).

2 g/m

3

........................

25 to 35 microns ...................

(a) 10-minutes for

power below sus-

tainable level flight

(idle descent).

(b) Must show repet-

itive, stabilized op-

eration for higher

powers (50%, 75%,

100%MC).

2. Rime ice conditions

¥

10 to 0

°

F (

¥

23 to

¥

18

°

C).

1 g/m

3

........................

15 to 25 microns ...................

(a) 10-minutes for

power below sus-

tainable level flight

(idle descent).

(b) Must show repet-

itive, stabilized op-

eration for higher

powers (50%, 75%,

100%MC).

VerDate Sep<11>2014

09:06 Jun 28, 2024

Jkt 262046

PO 00000

Frm 00725

Fmt 8010

Sfmt 8010

Y:\SGML\262046.XXX

262046

jspears on DSK121TN23PROD with CFR

716

14 CFR Ch. I (1–1–24 Edition)

§ 33.69

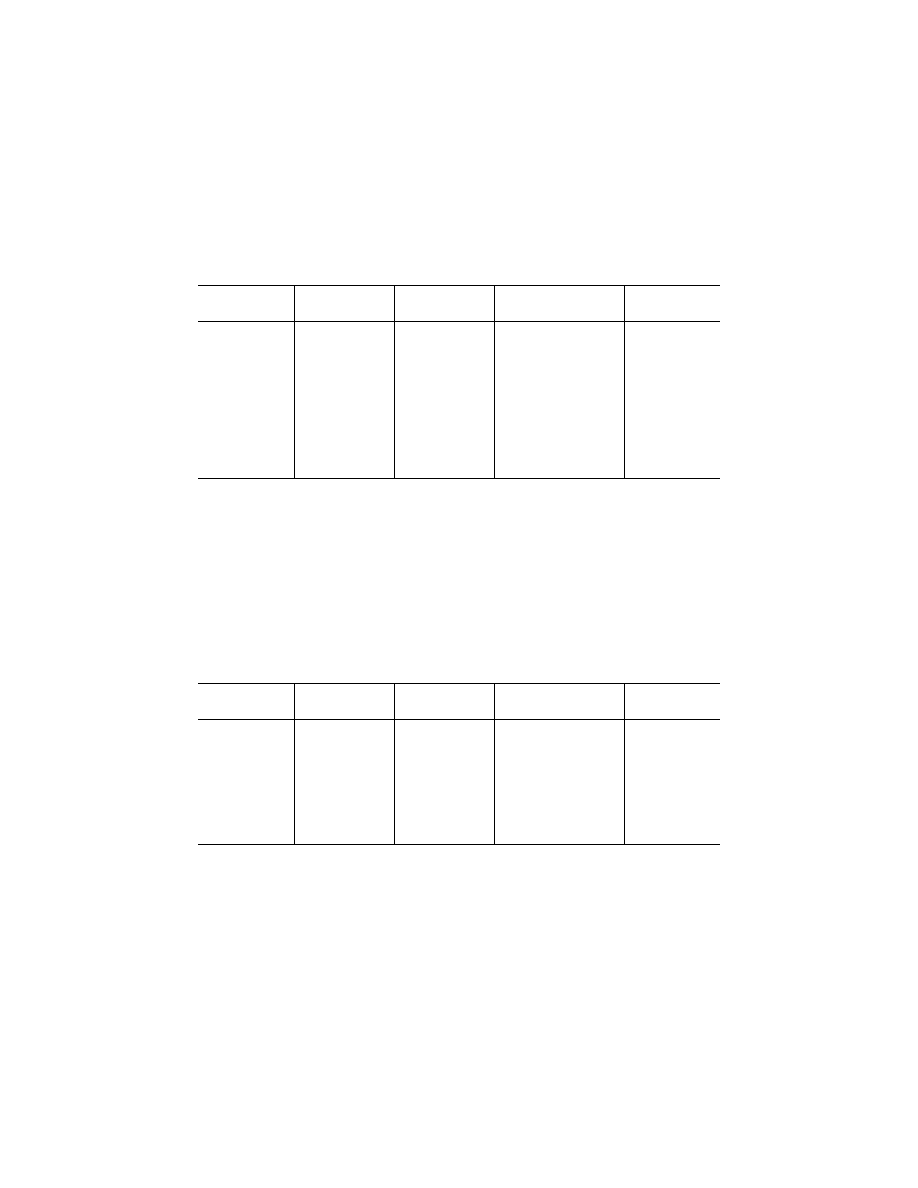

T

ABLE

1—C

ONDITIONS

T

HAT

M

UST

B

E

D

EMONSTRATED BY AN

E

NGINE

T

EST

—Continued

Condition

Total air temperature

Supercooled water

concentrations

(minimum)

Median volume drop diameter

Duration

3. Glaze ice holding

conditions.

(Turbojet, turbofan,

and turboprop only).

Turbojet and Tur-

bofan, only: 10 to

18

°

F (

¥

12 to

¥

8

°

C).

Alternating cycle: First

1.7 g/m

3

(1 minute),

Then 0.3 g/m

3

(6

minute).

20 to 30 microns ...................

Must show repetitive,

stabilized operation

(or 45 minutes

max).

Turboprop, only: 2 to

10

°

F (

¥

17 to

¥

12

°

C).

.

4. Rime ice holding

conditions.

(Turbojet, turbofan,

and turboprop only).

Turbojet and Tur-

bofan, only:

¥

10 to

0

°

F (

¥

23 to

¥

18

°

C).

0.25 g/m

3

...................

20 to 30 microns ...................

Must show repetitive,

stabilized operation

(or 45 minutes

max).

Turboprop, only: 2 to

10

°

F (

¥

17 to

¥

12

°

C).

....................................

................................................

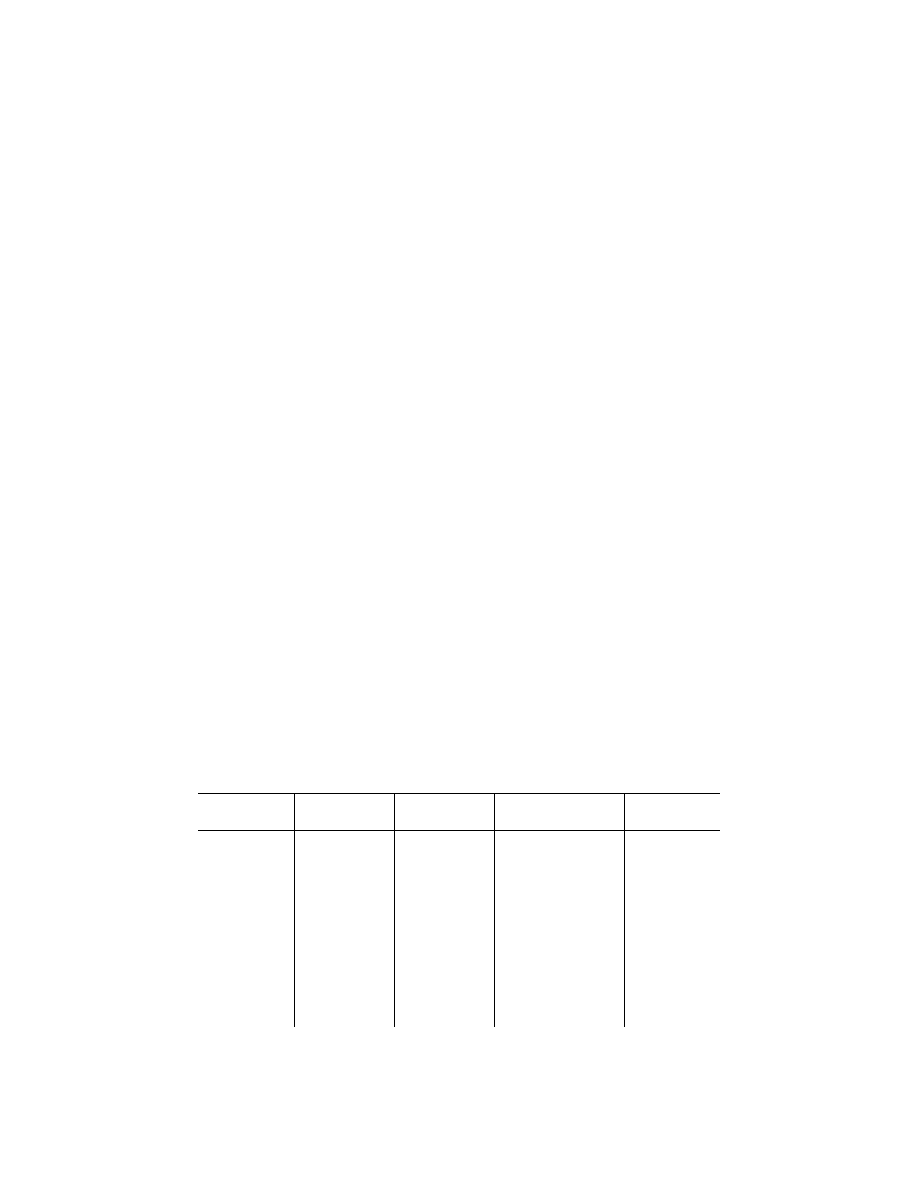

(d) Operate at ground idle speed for a

minimum of 30 minutes at each of the

following icing conditions shown in

Table 2 of this section with the avail-

able air bleed for icing protection at its

critical condition, without adverse ef-

fect, followed by acceleration to take-

off power or thrust. During the idle op-

eration, the engine may be run up peri-

odically to a moderate power or thrust

setting in a manner acceptable to the

Administrator. Analysis may be used

to show ambient temperatures below

the tested temperature are less crit-

ical. The applicant must document any

demonstrated run ups and minimum

ambient temperature capability in the

engine operating manual as mandatory

in icing conditions. The applicant must

demonstrate, with consideration of ex-

pected airport elevations, the fol-

lowing:

T

ABLE

2—D

EMONSTRATION

M

ETHODS FOR

S

PECIFIC

I

CING

C

ONDITIONS

Condition

Total air temperature

Supercooled water

concentrations

(minimum)

Mean effective particle di-

ameter

Demonstration

1. Rime ice condition

0 to 15

°

F (

¥

18 to

¥

9

°

C).

Liquid—0.3 g/m

3

........

15–25 microns .......................

By engine test.

2. Glaze ice condition

20 to 30

°

F (

¥

7 to

¥

1

°

C).

Liquid—0.3 g/m

3

........

15–25 microns .......................

By engine test.

3. Snow ice condition

26 to 32

°

F (

¥

3 to 0

°

C).

Ice—0.9 g/m

3

............

100 microns ...........................

(minimum) ..............................

By test, analysis or

combination of the

two.

4. Large drop glaze

ice condition (Tur-

bojet, turbofan, and

turboprop only).

15 to 30

°

F (-9 to -1

°

C).

Liquid—0.3 g/m

3

........

100 microns (minimum) .........

By test, analysis or

combination of the

two.

(e) Demonstrate by test, analysis, or

combination of the two, acceptable op-

eration for turbojet, turbofan, and tur-

boprop engines in mixed phase and ice

crystal icing conditions throughout

Appendix D of this part, icing envelope

throughout its flight power range, in-

cluding minimum descent idling

speeds.

[Amdt. 33–34, 79 FR 66536, Nov. 4, 2014]

§ 33.69

Ignitions system.

Each engine must be equipped with

an ignition system for starting the en-

gine on the ground and in flight. An

electric ignition system must have at

least two igniters and two separate sec-

ondary electric circuits, except that

only one igniter is required for fuel

burning augmentation systems.

[Amdt. 33–6, 39 FR 35466, Oct. 1, 1974]

VerDate Sep<11>2014

09:06 Jun 28, 2024

Jkt 262046

PO 00000

Frm 00726

Fmt 8010

Sfmt 8010

Y:\SGML\262046.XXX

262046

jspears on DSK121TN23PROD with CFR