716

14 CFR Ch. I (1–1–24 Edition)

§ 33.69

T

ABLE

1—C

ONDITIONS

T

HAT

M

UST

B

E

D

EMONSTRATED BY AN

E

NGINE

T

EST

—Continued

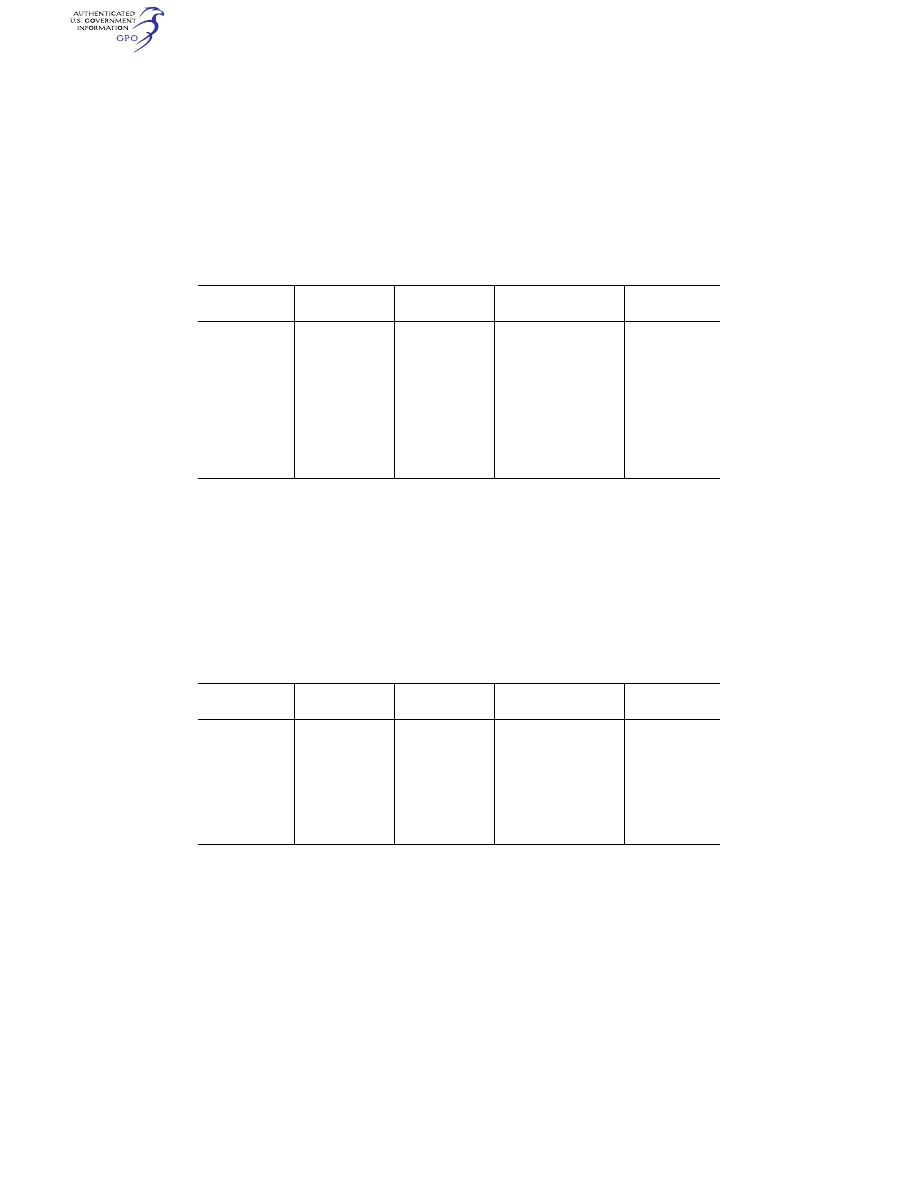

Condition

Total air temperature

Supercooled water

concentrations

(minimum)

Median volume drop diameter

Duration

3. Glaze ice holding

conditions.

(Turbojet, turbofan,

and turboprop only).

Turbojet and Tur-

bofan, only: 10 to

18

°

F (

¥

12 to

¥

8

°

C).

Alternating cycle: First

1.7 g/m

3

(1 minute),

Then 0.3 g/m

3

(6

minute).

20 to 30 microns ...................

Must show repetitive,

stabilized operation

(or 45 minutes

max).

Turboprop, only: 2 to

10

°

F (

¥

17 to

¥

12

°

C).

.

4. Rime ice holding

conditions.

(Turbojet, turbofan,

and turboprop only).

Turbojet and Tur-

bofan, only:

¥

10 to

0

°

F (

¥

23 to

¥

18

°

C).

0.25 g/m

3

...................

20 to 30 microns ...................

Must show repetitive,

stabilized operation

(or 45 minutes

max).

Turboprop, only: 2 to

10

°

F (

¥

17 to

¥

12

°

C).

....................................

................................................

(d) Operate at ground idle speed for a

minimum of 30 minutes at each of the

following icing conditions shown in

Table 2 of this section with the avail-

able air bleed for icing protection at its

critical condition, without adverse ef-

fect, followed by acceleration to take-

off power or thrust. During the idle op-

eration, the engine may be run up peri-

odically to a moderate power or thrust

setting in a manner acceptable to the

Administrator. Analysis may be used

to show ambient temperatures below

the tested temperature are less crit-

ical. The applicant must document any

demonstrated run ups and minimum

ambient temperature capability in the

engine operating manual as mandatory

in icing conditions. The applicant must

demonstrate, with consideration of ex-

pected airport elevations, the fol-

lowing:

T

ABLE

2—D

EMONSTRATION

M

ETHODS FOR

S

PECIFIC

I

CING

C

ONDITIONS

Condition

Total air temperature

Supercooled water

concentrations

(minimum)

Mean effective particle di-

ameter

Demonstration

1. Rime ice condition

0 to 15

°

F (

¥

18 to

¥

9

°

C).

Liquid—0.3 g/m

3

........

15–25 microns .......................

By engine test.

2. Glaze ice condition

20 to 30

°

F (

¥

7 to

¥

1

°

C).

Liquid—0.3 g/m

3

........

15–25 microns .......................

By engine test.

3. Snow ice condition

26 to 32

°

F (

¥

3 to 0

°

C).

Ice—0.9 g/m

3

............

100 microns ...........................

(minimum) ..............................

By test, analysis or

combination of the

two.

4. Large drop glaze

ice condition (Tur-

bojet, turbofan, and

turboprop only).

15 to 30

°

F (-9 to -1

°

C).

Liquid—0.3 g/m

3

........

100 microns (minimum) .........

By test, analysis or

combination of the

two.

(e) Demonstrate by test, analysis, or

combination of the two, acceptable op-

eration for turbojet, turbofan, and tur-

boprop engines in mixed phase and ice

crystal icing conditions throughout

Appendix D of this part, icing envelope

throughout its flight power range, in-

cluding minimum descent idling

speeds.

[Amdt. 33–34, 79 FR 66536, Nov. 4, 2014]

§ 33.69

Ignitions system.

Each engine must be equipped with

an ignition system for starting the en-

gine on the ground and in flight. An

electric ignition system must have at

least two igniters and two separate sec-

ondary electric circuits, except that

only one igniter is required for fuel

burning augmentation systems.

[Amdt. 33–6, 39 FR 35466, Oct. 1, 1974]

VerDate Sep<11>2014

09:06 Jun 28, 2024

Jkt 262046

PO 00000

Frm 00726

Fmt 8010

Sfmt 8010

Y:\SGML\262046.XXX

262046

jspears on DSK121TN23PROD with CFR