5

SUBCHAPTER D—AIRMEN

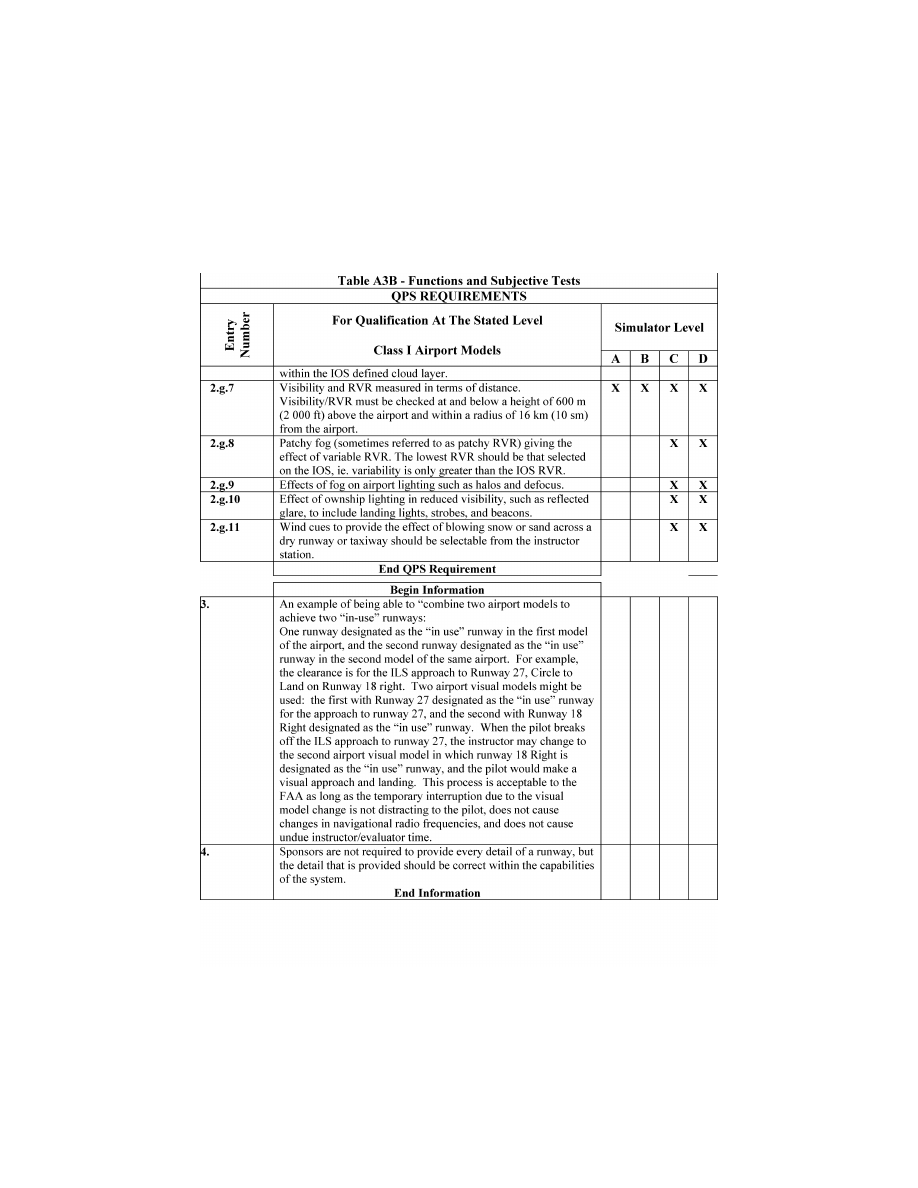

PART 60—FLIGHT SIMULATION

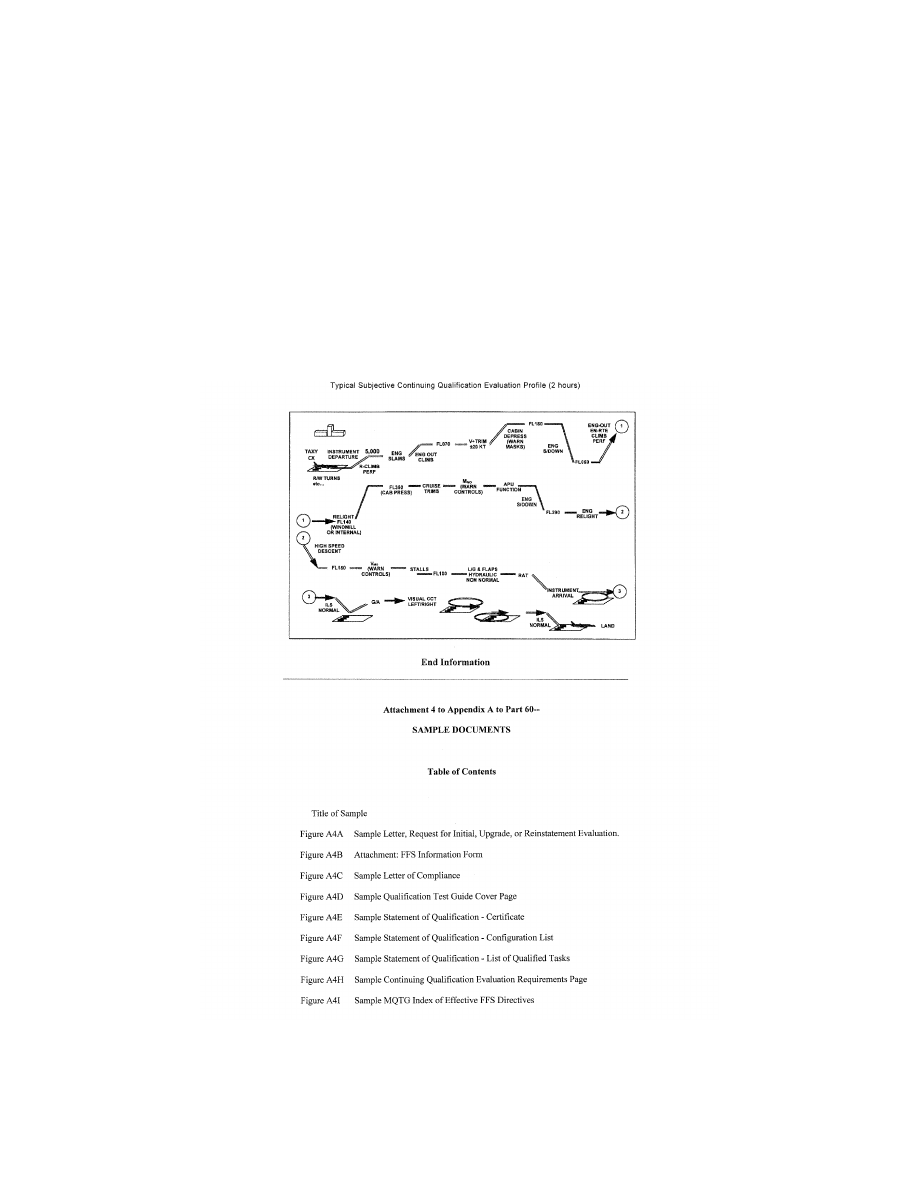

TRAINING DEVICE INITIAL AND

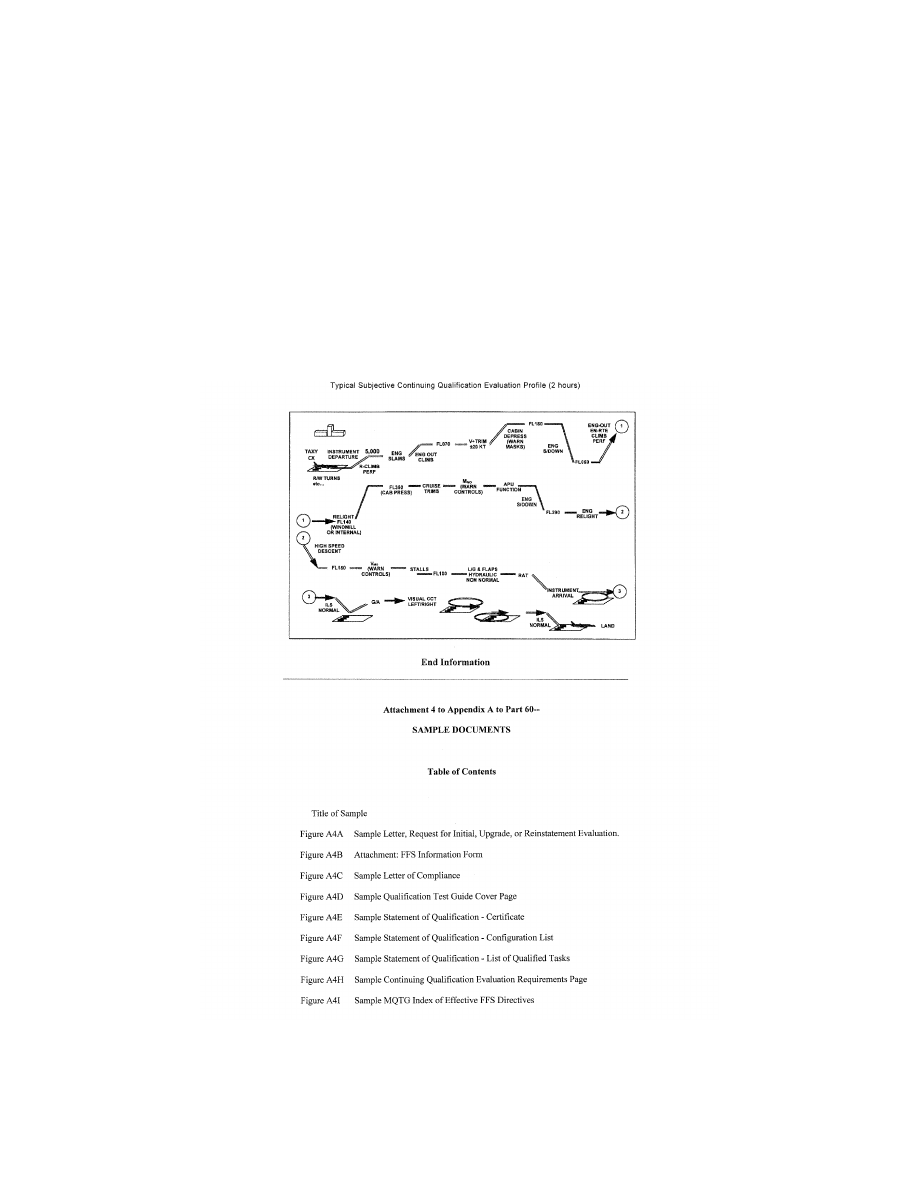

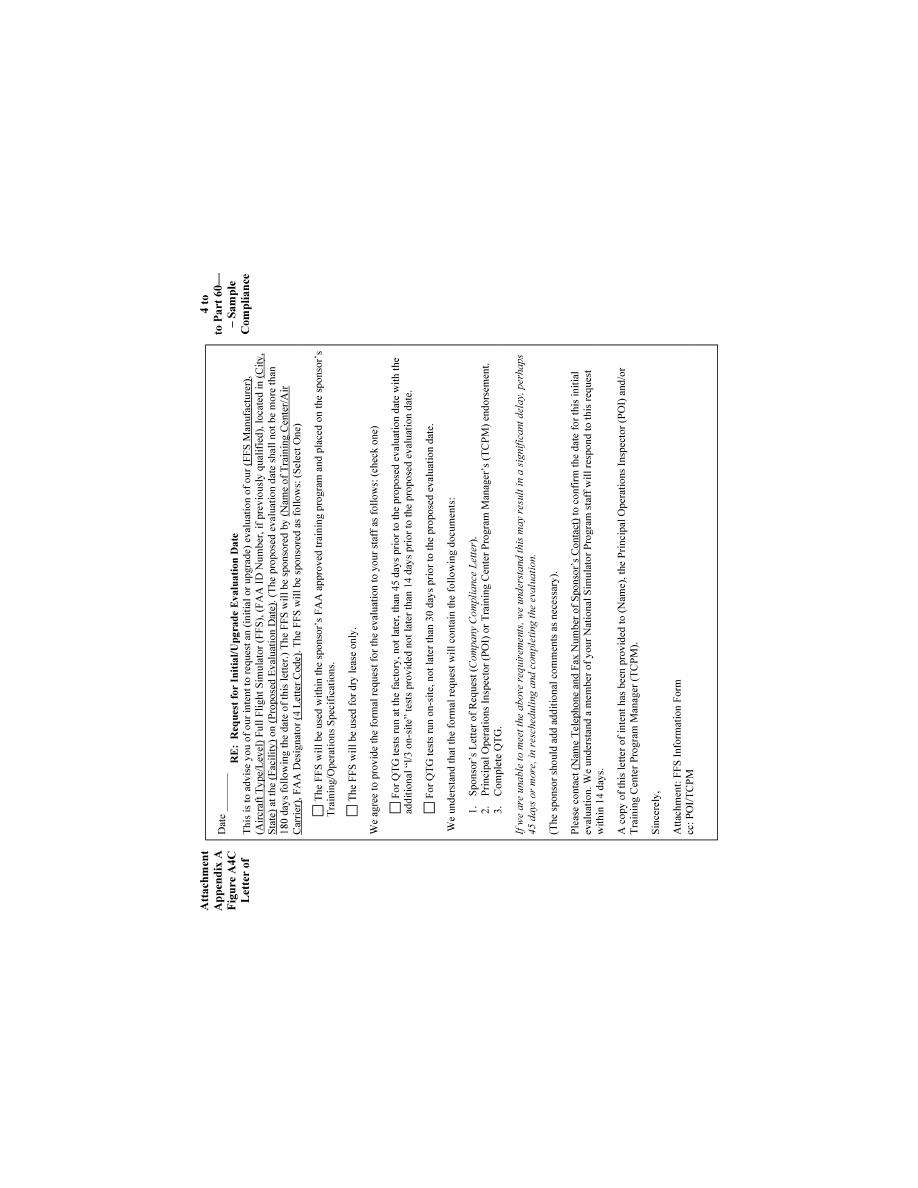

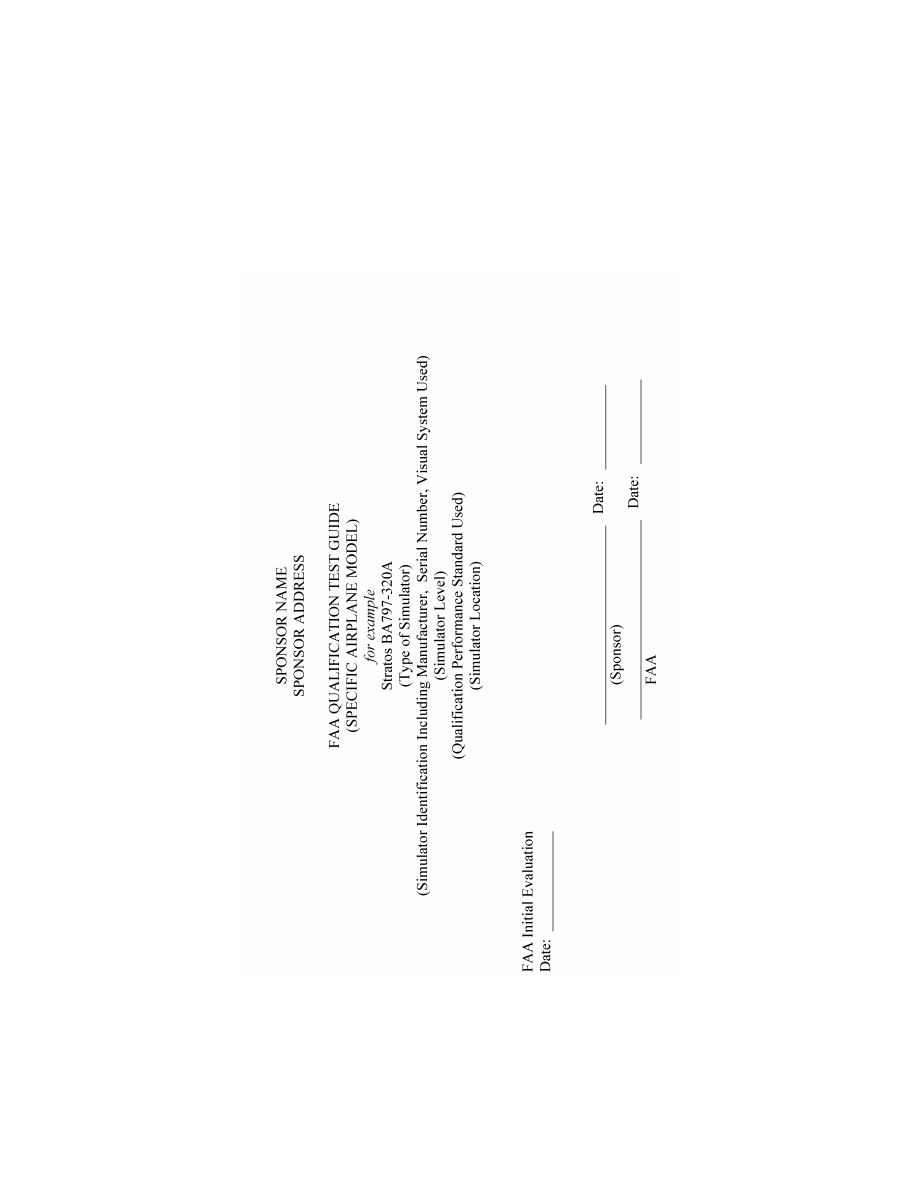

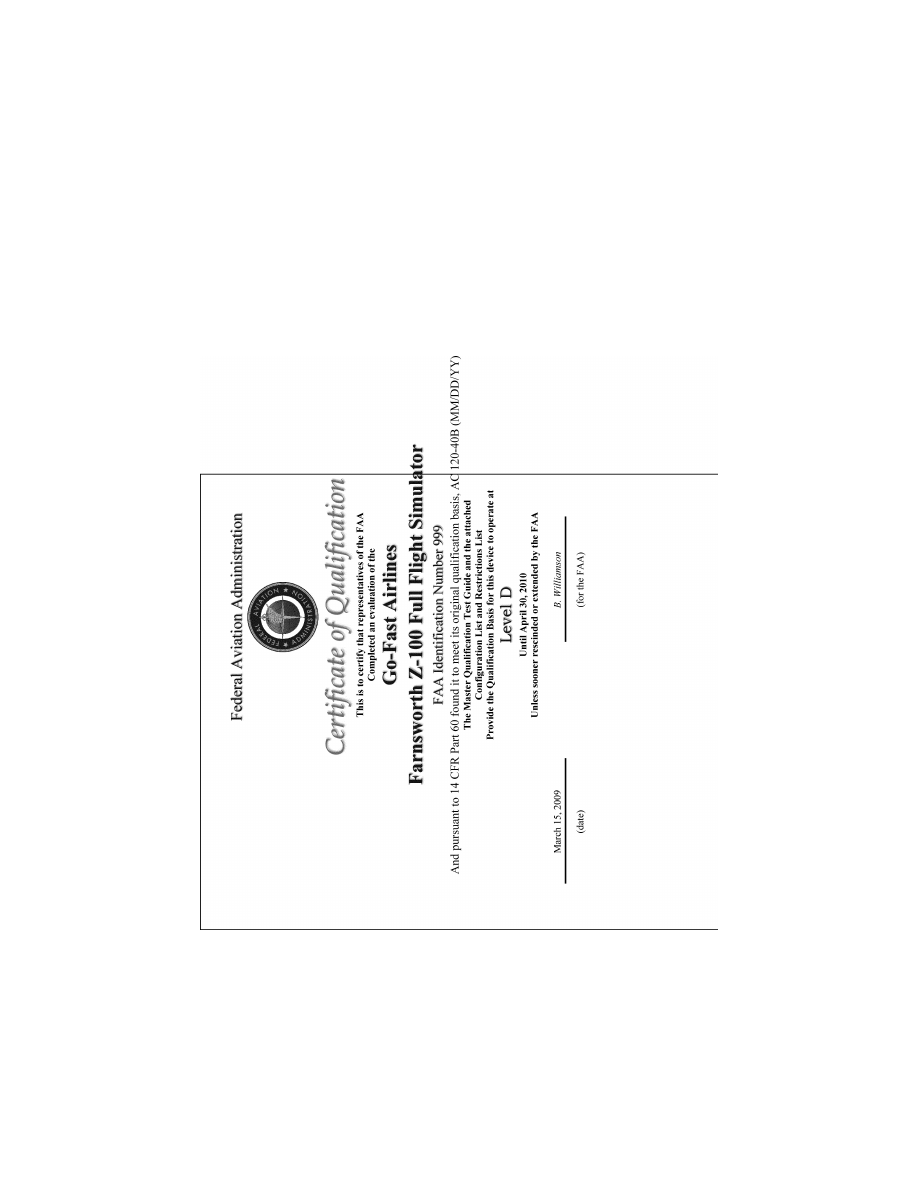

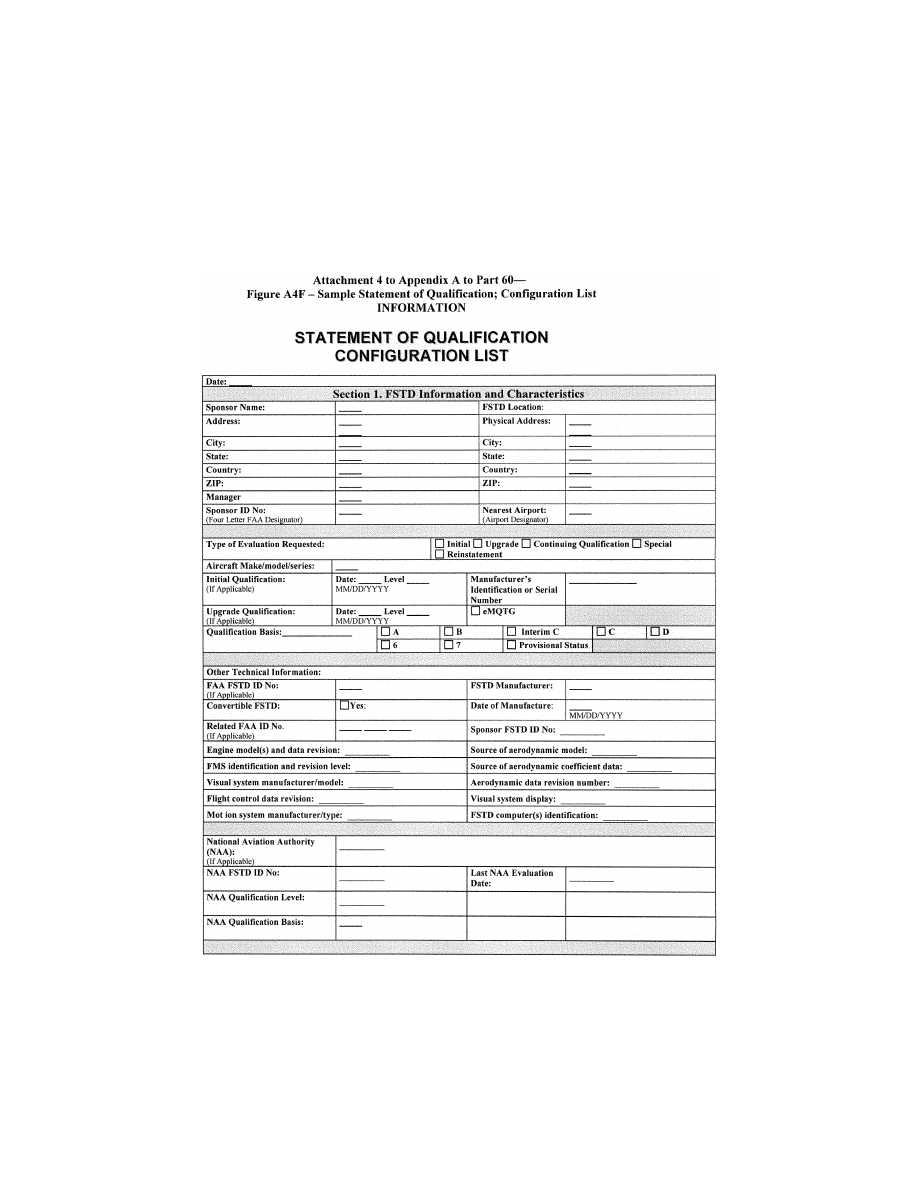

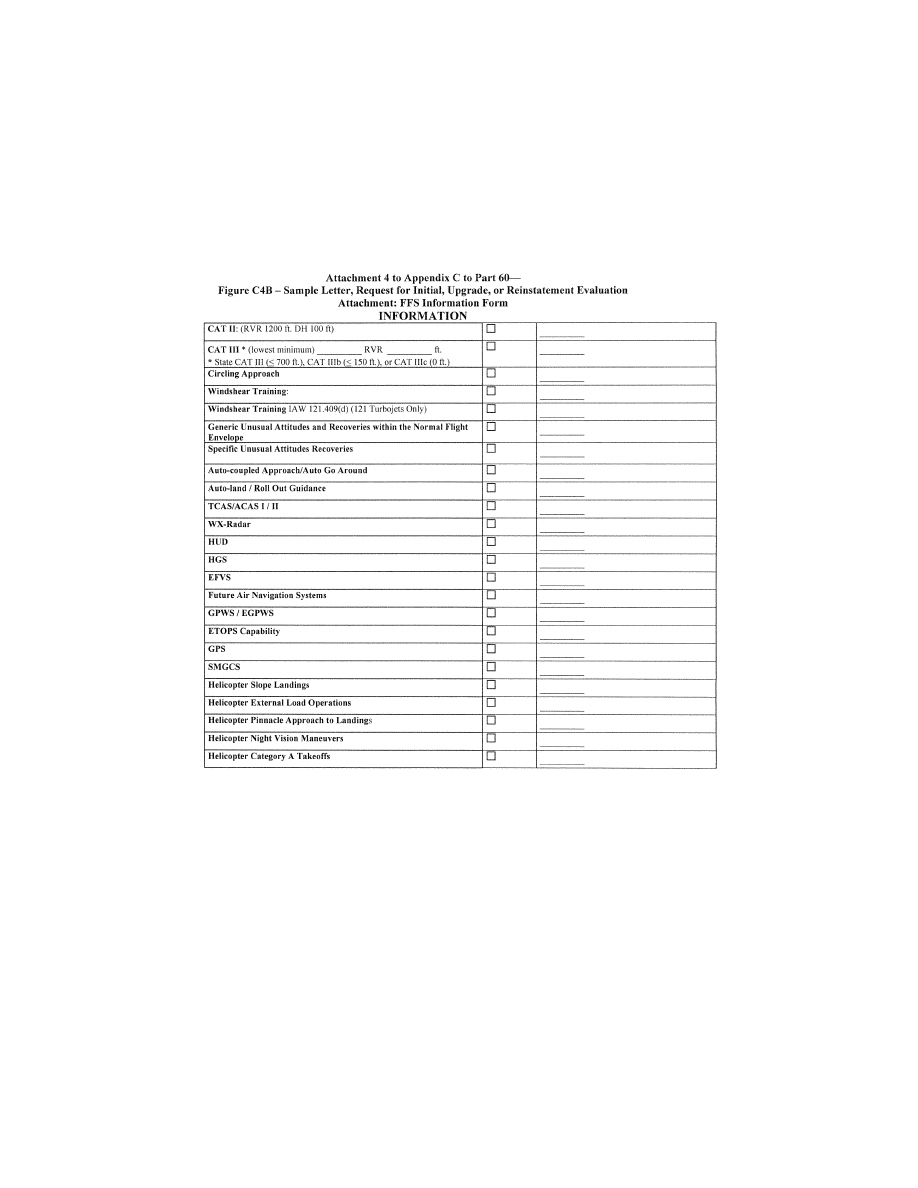

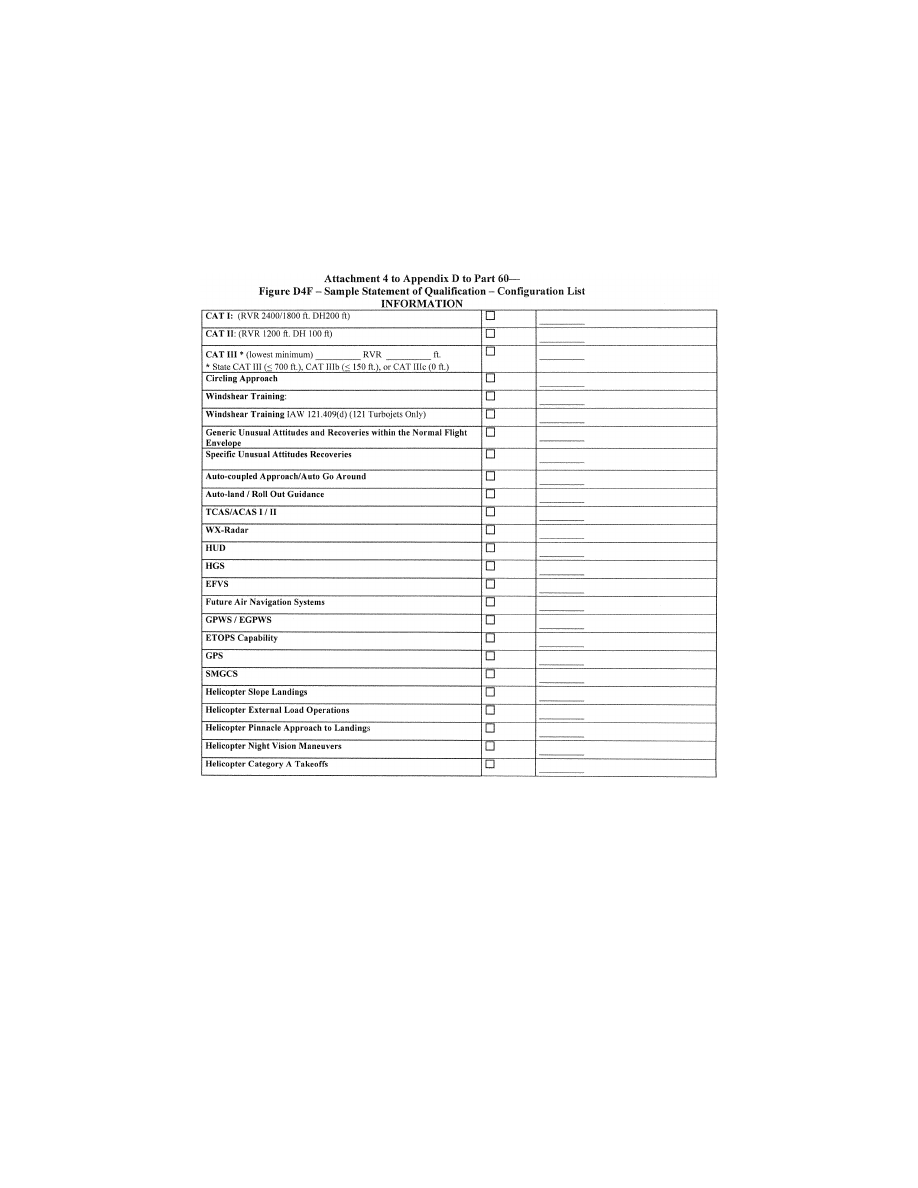

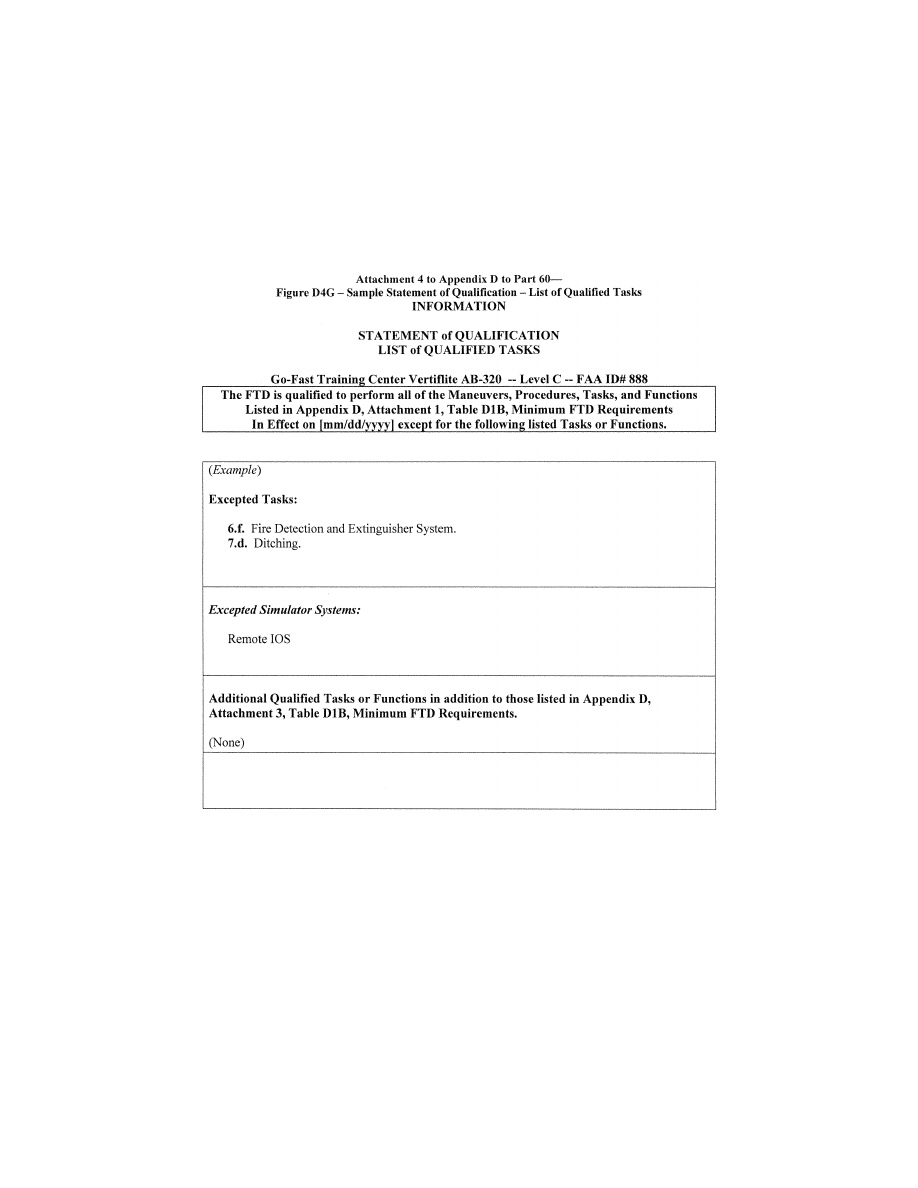

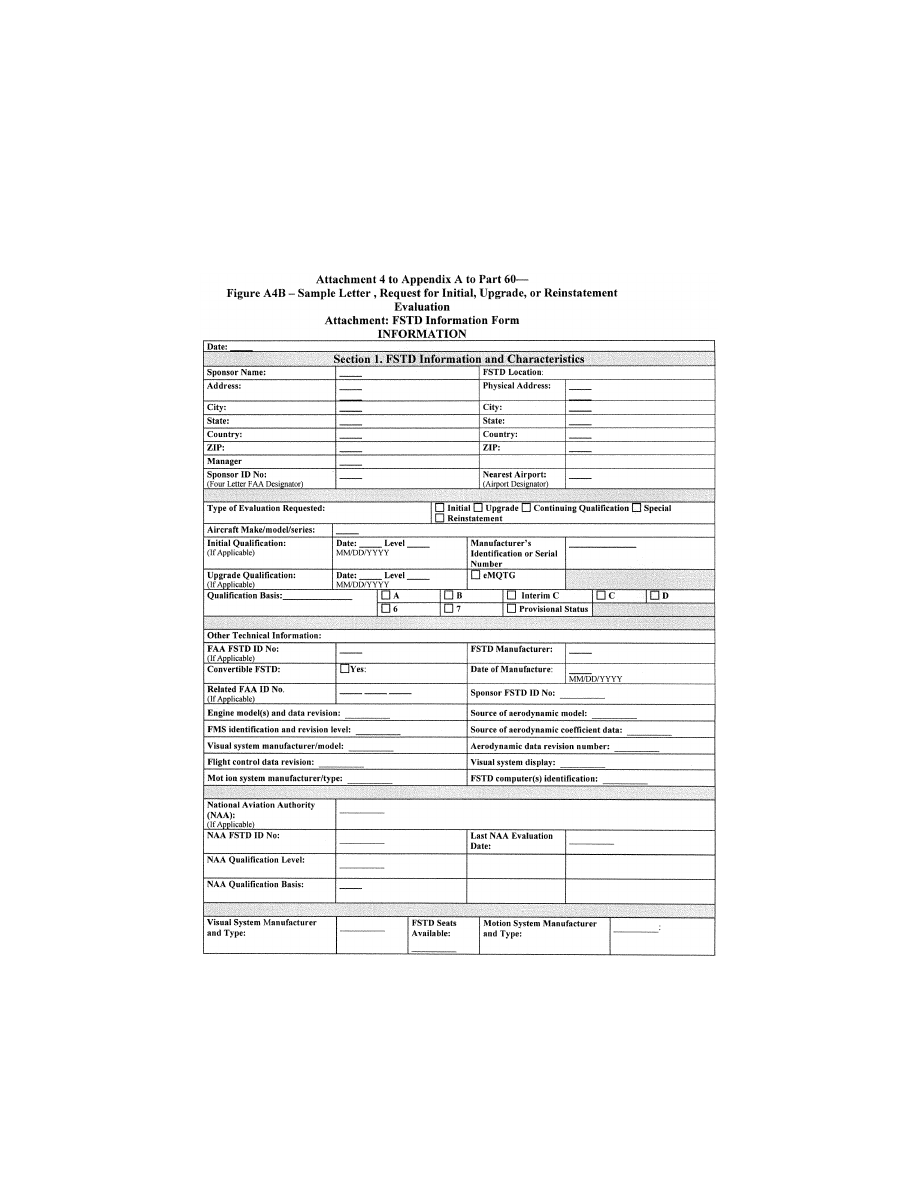

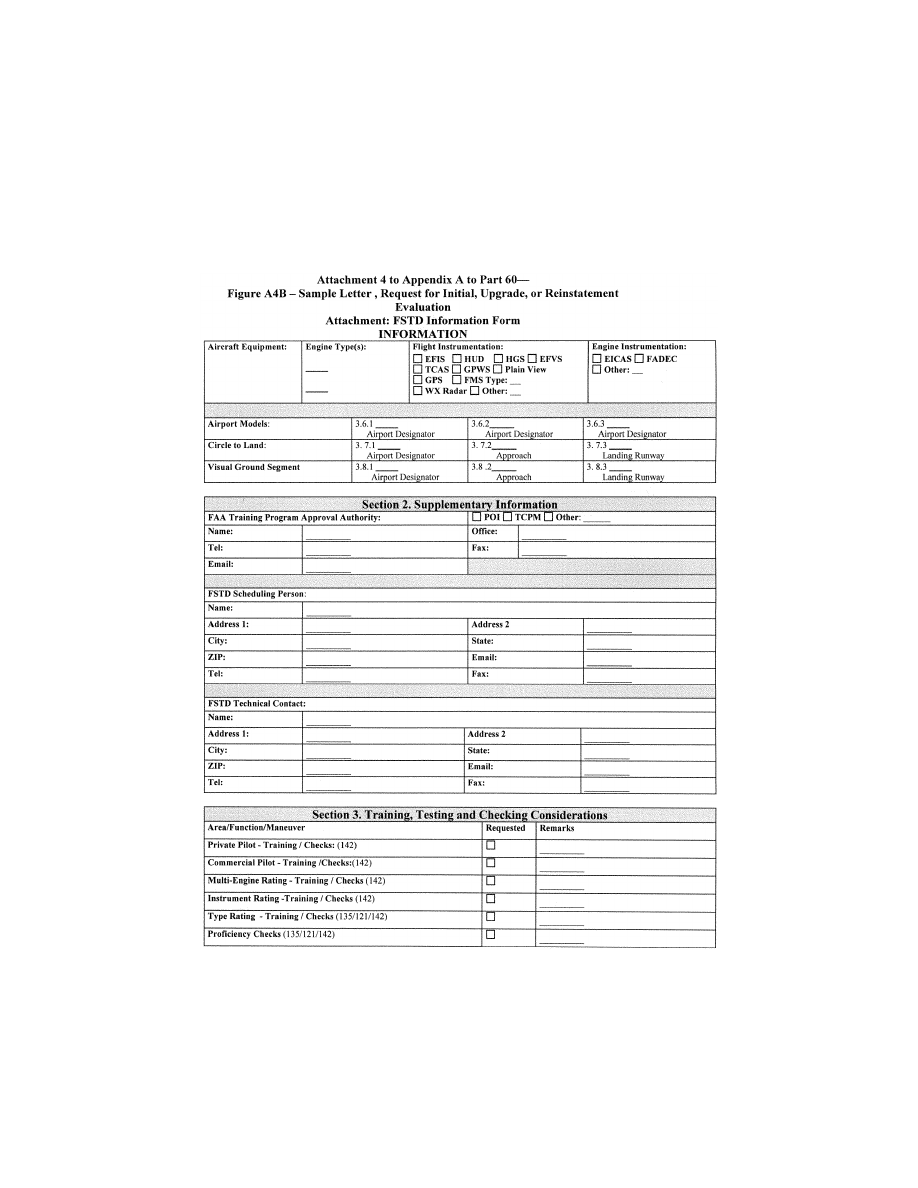

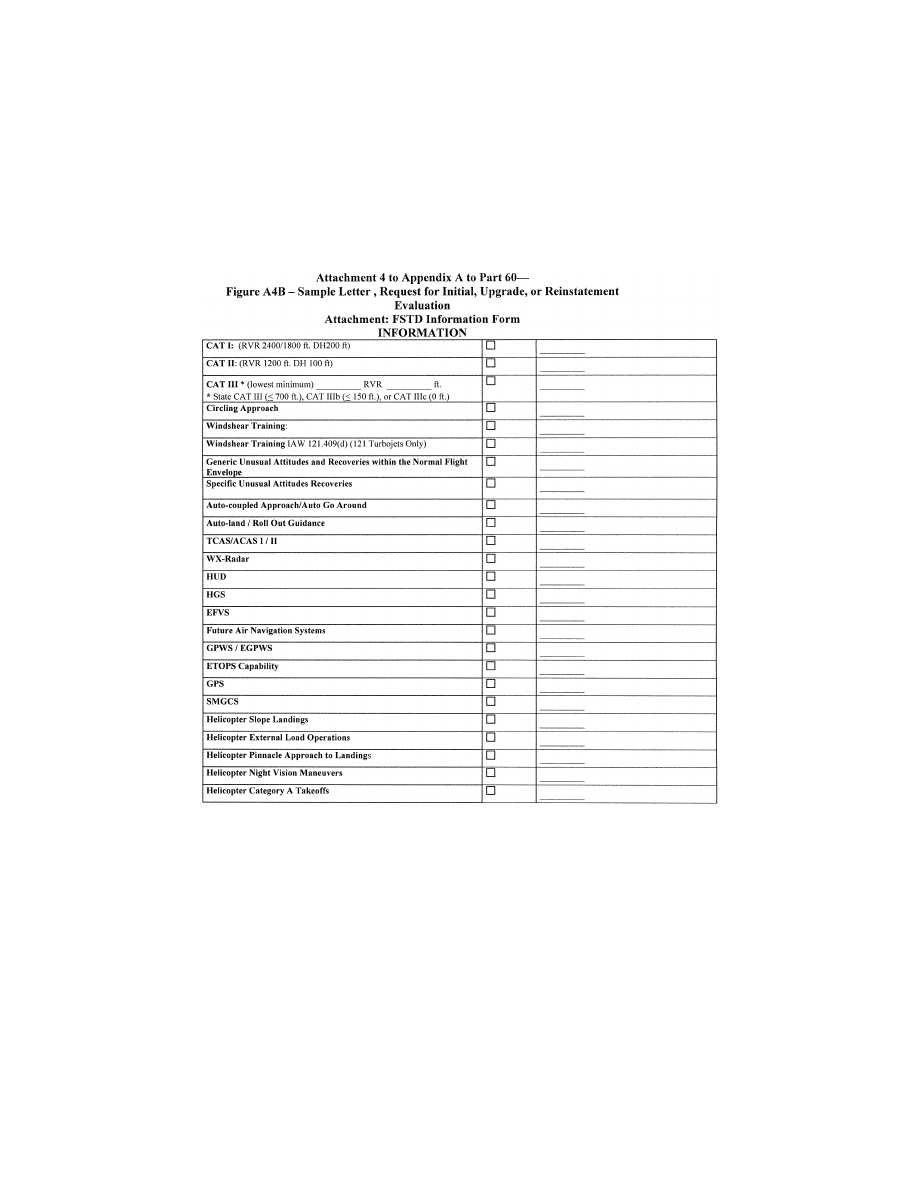

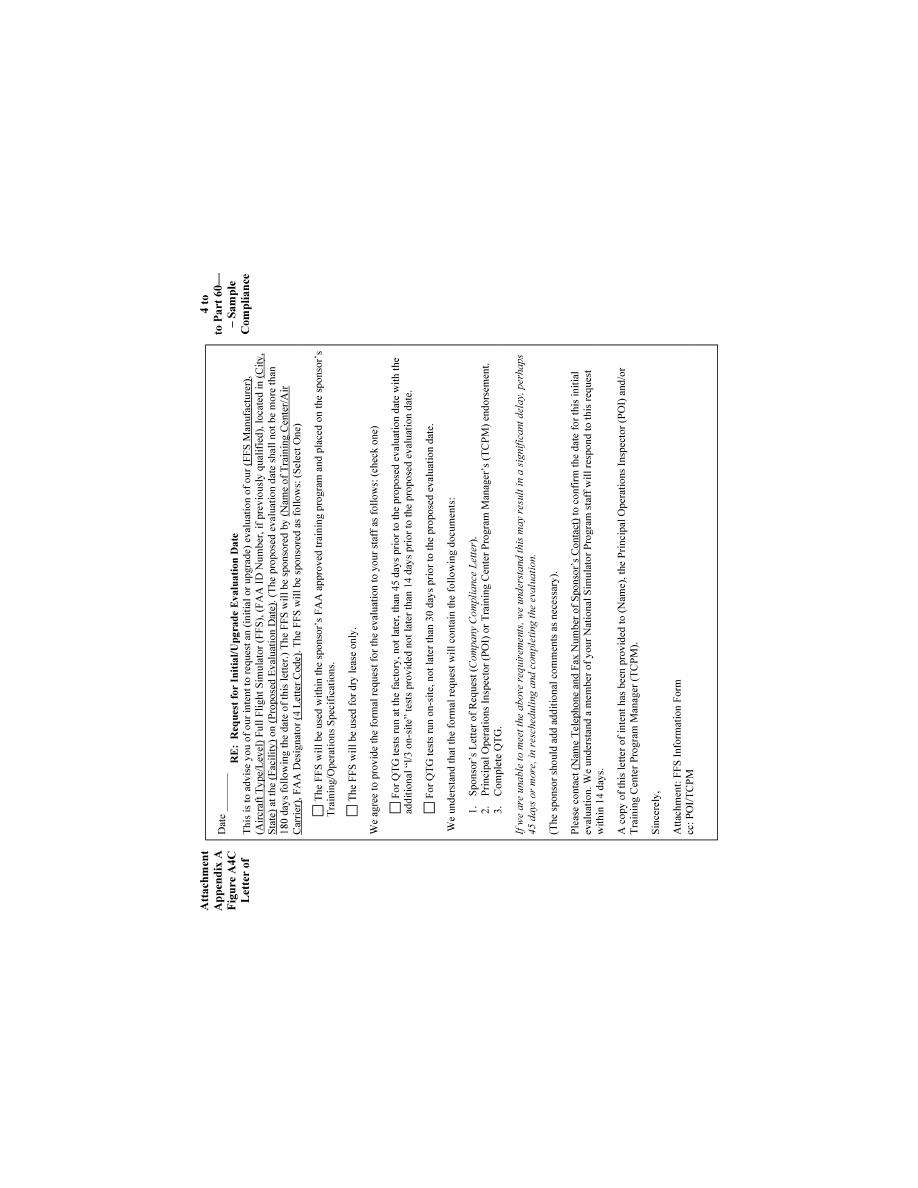

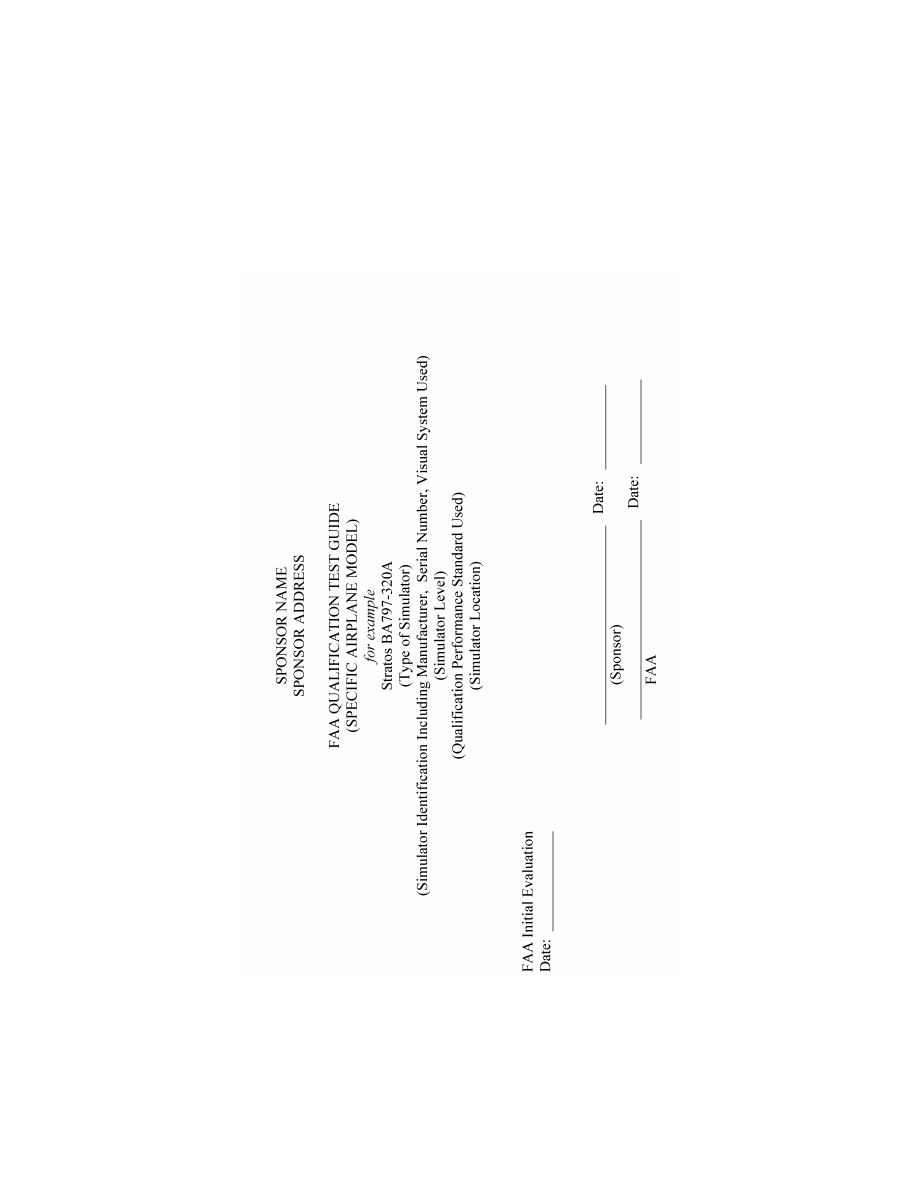

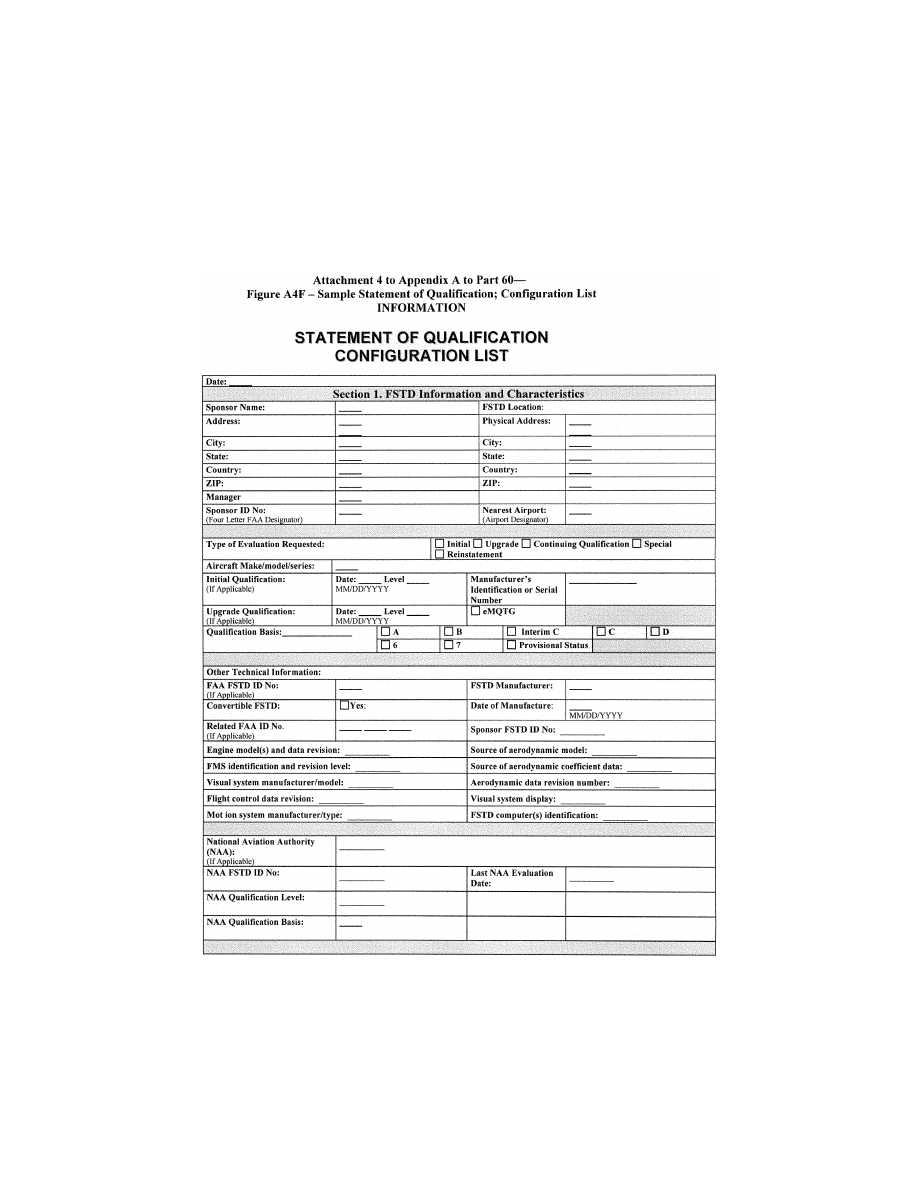

CONTINUING QUALIFICATION

AND USE

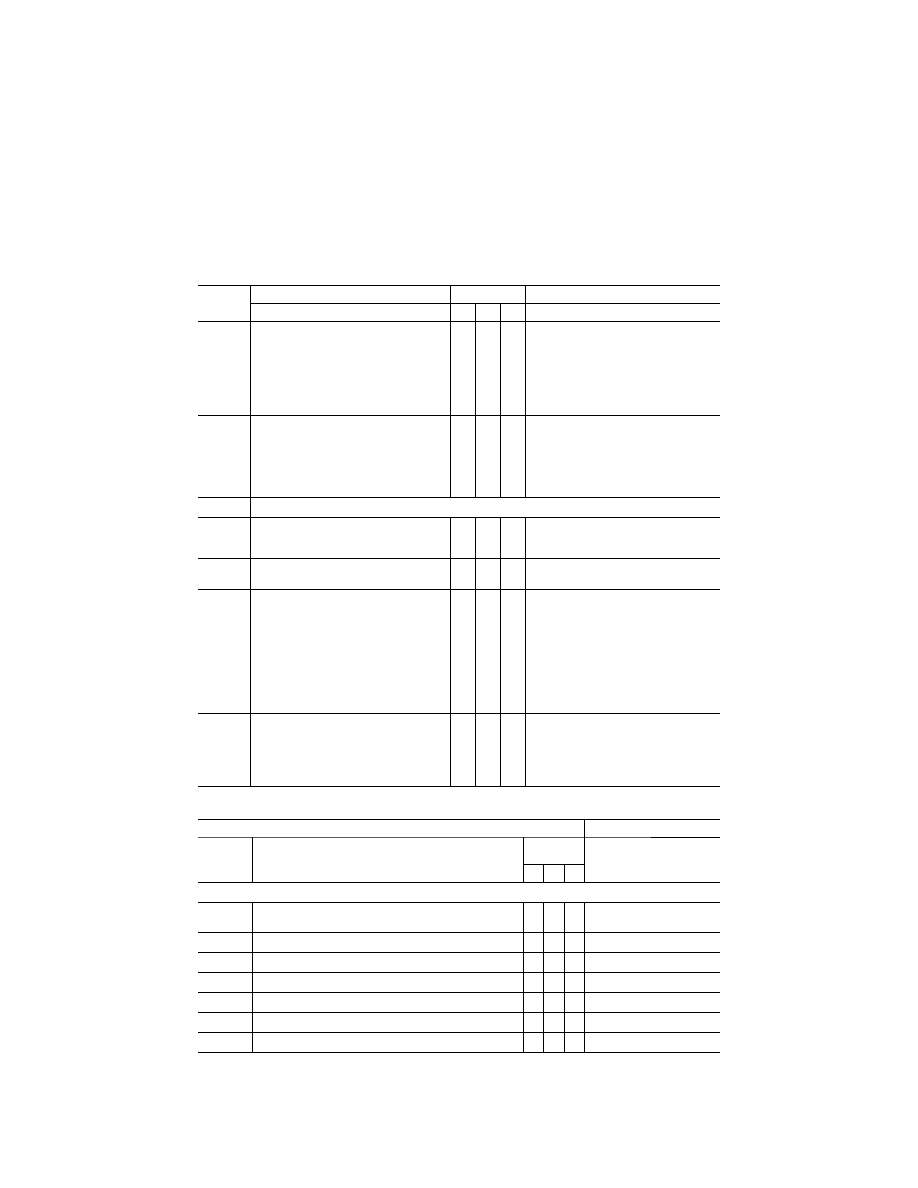

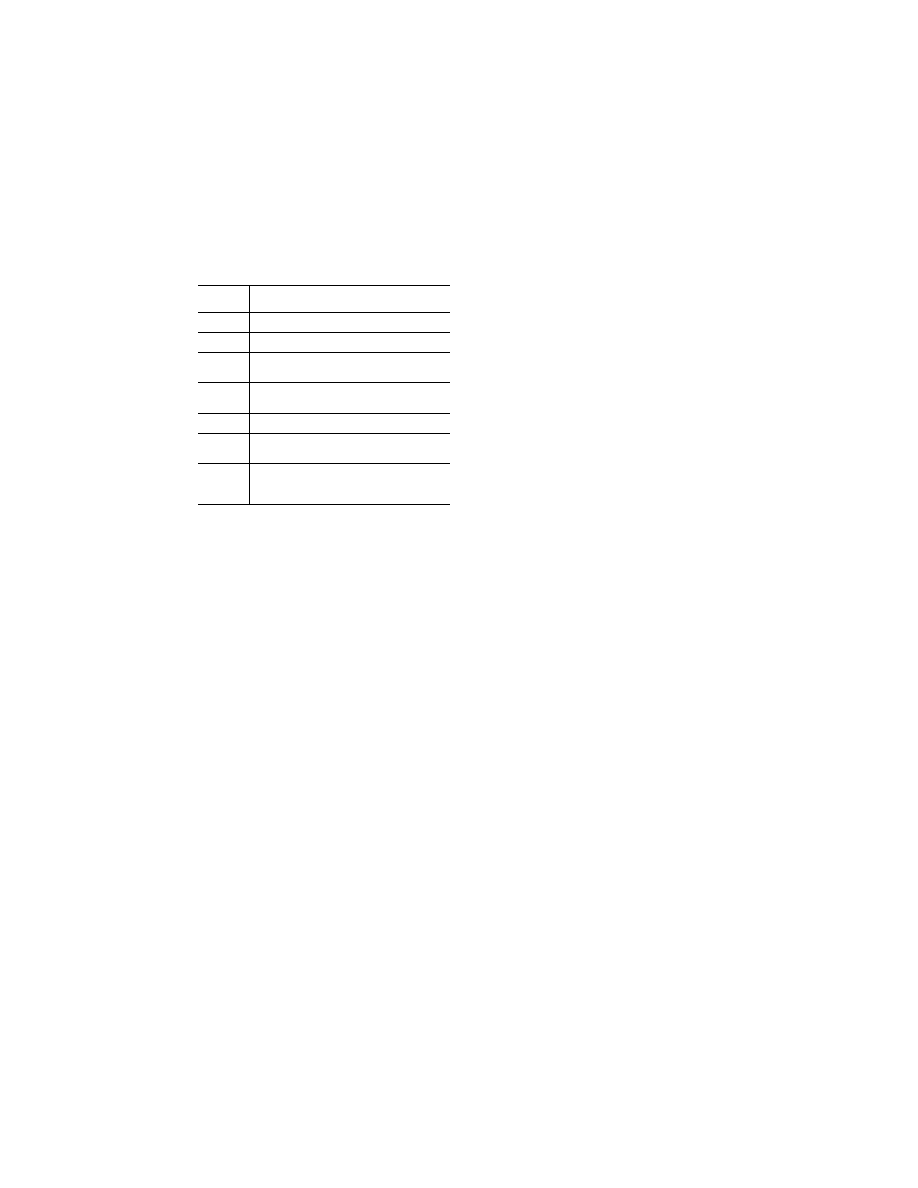

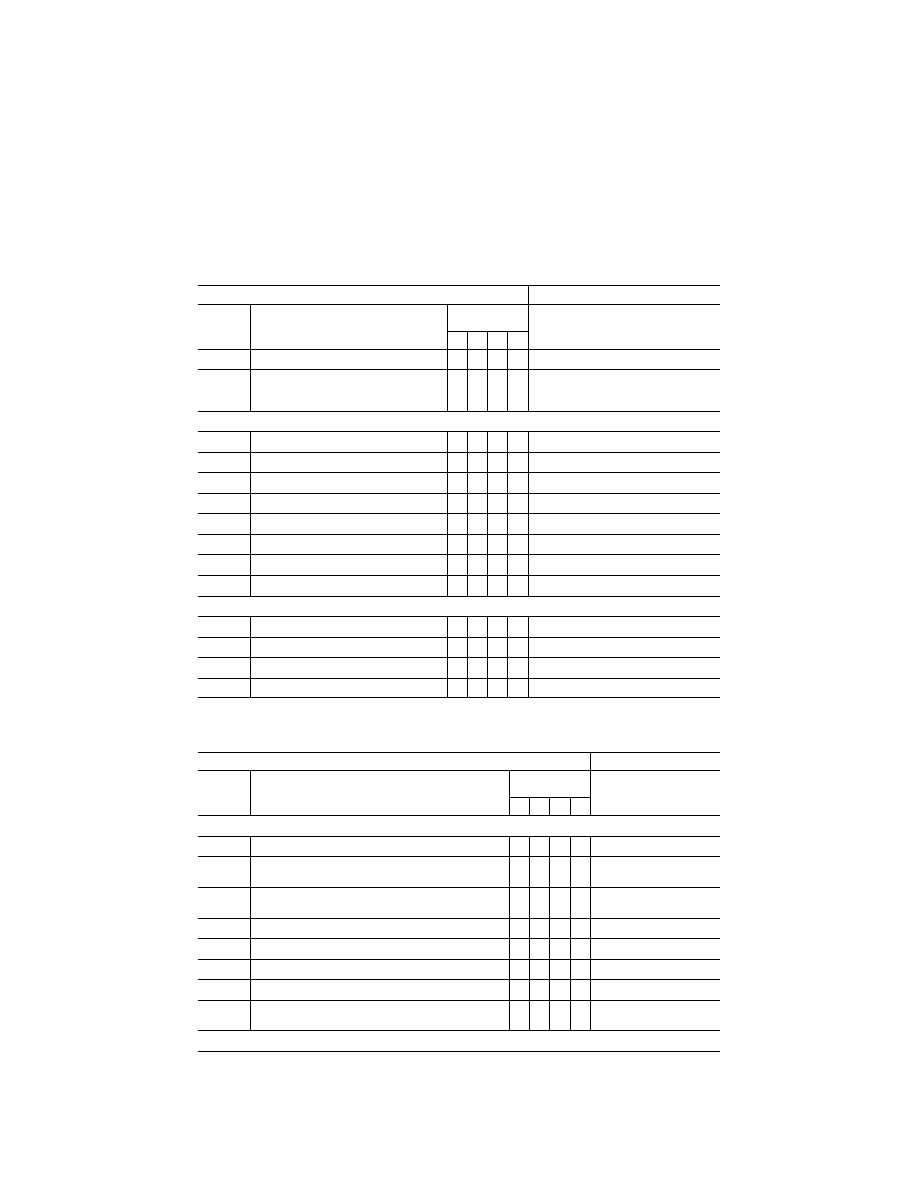

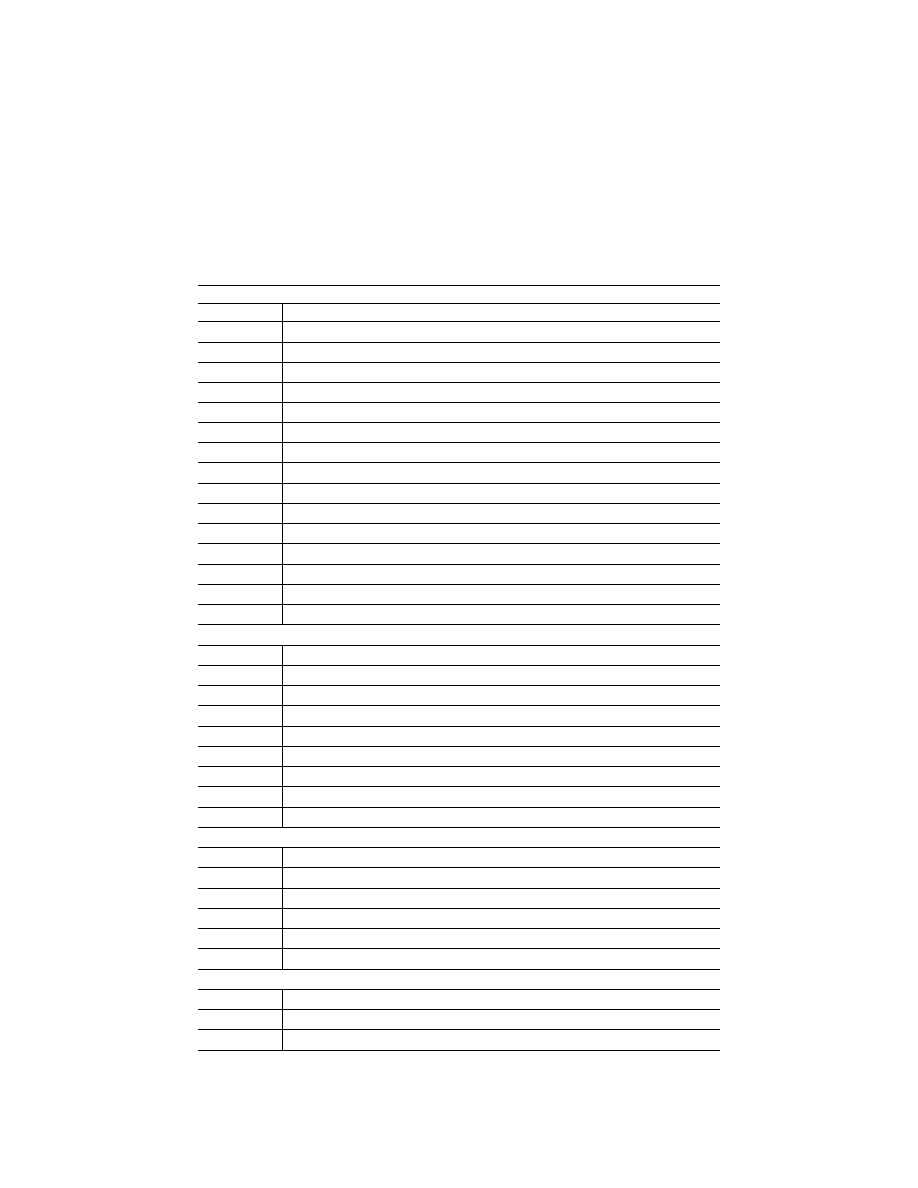

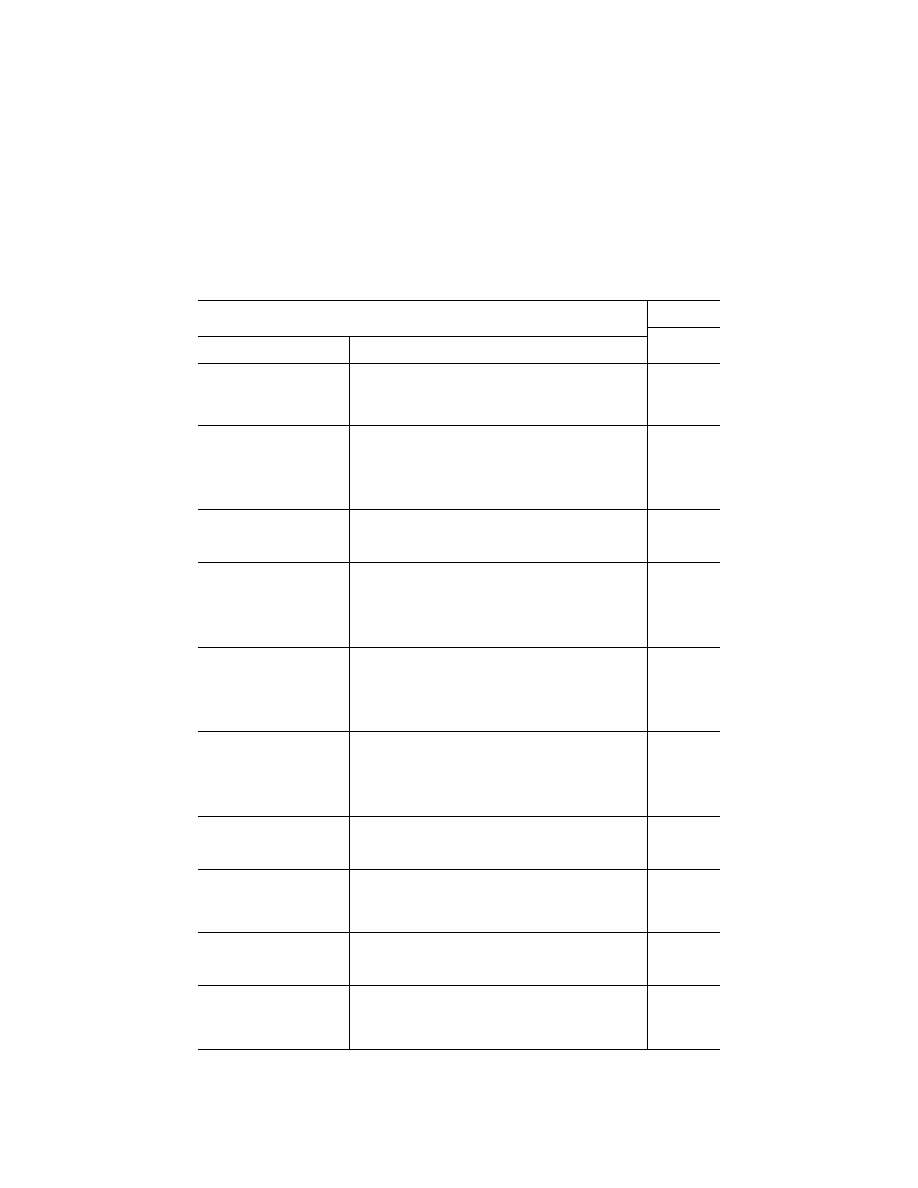

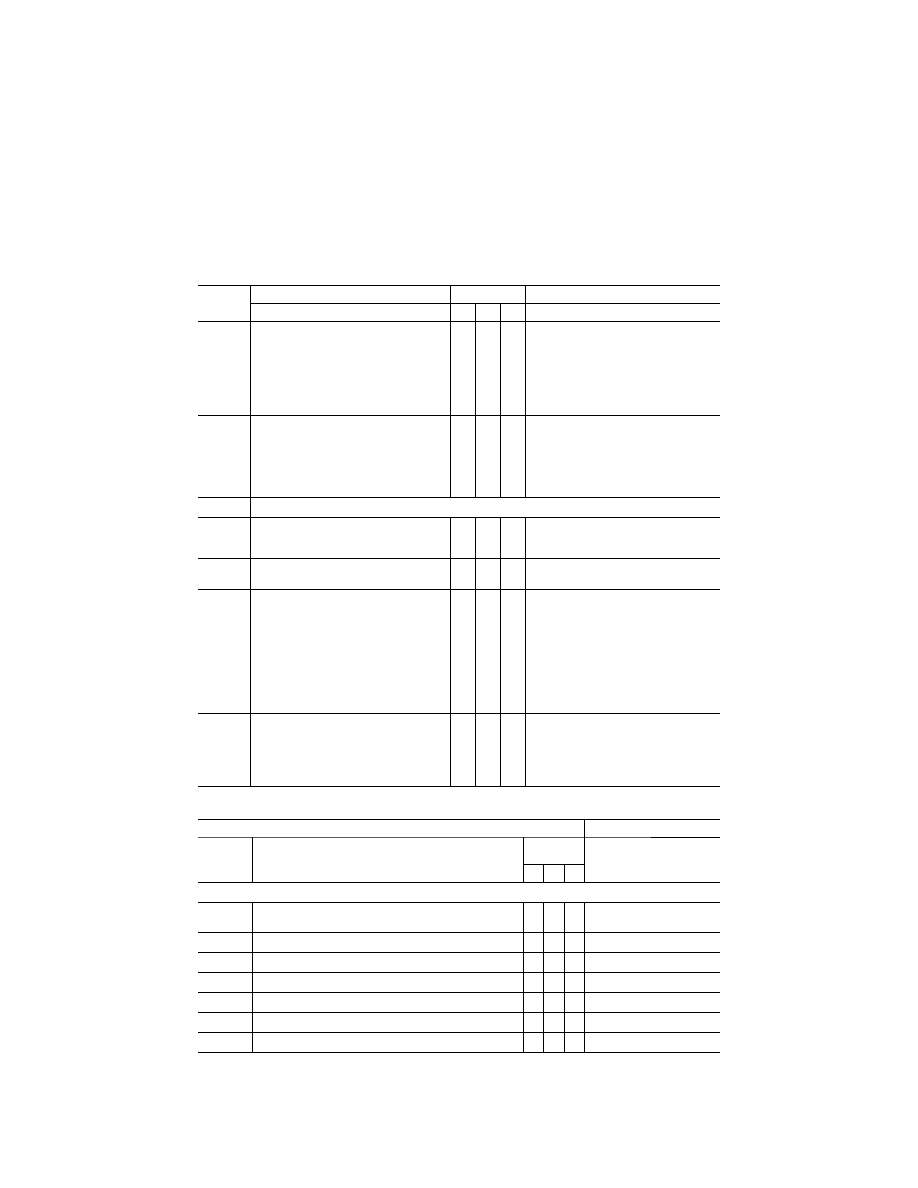

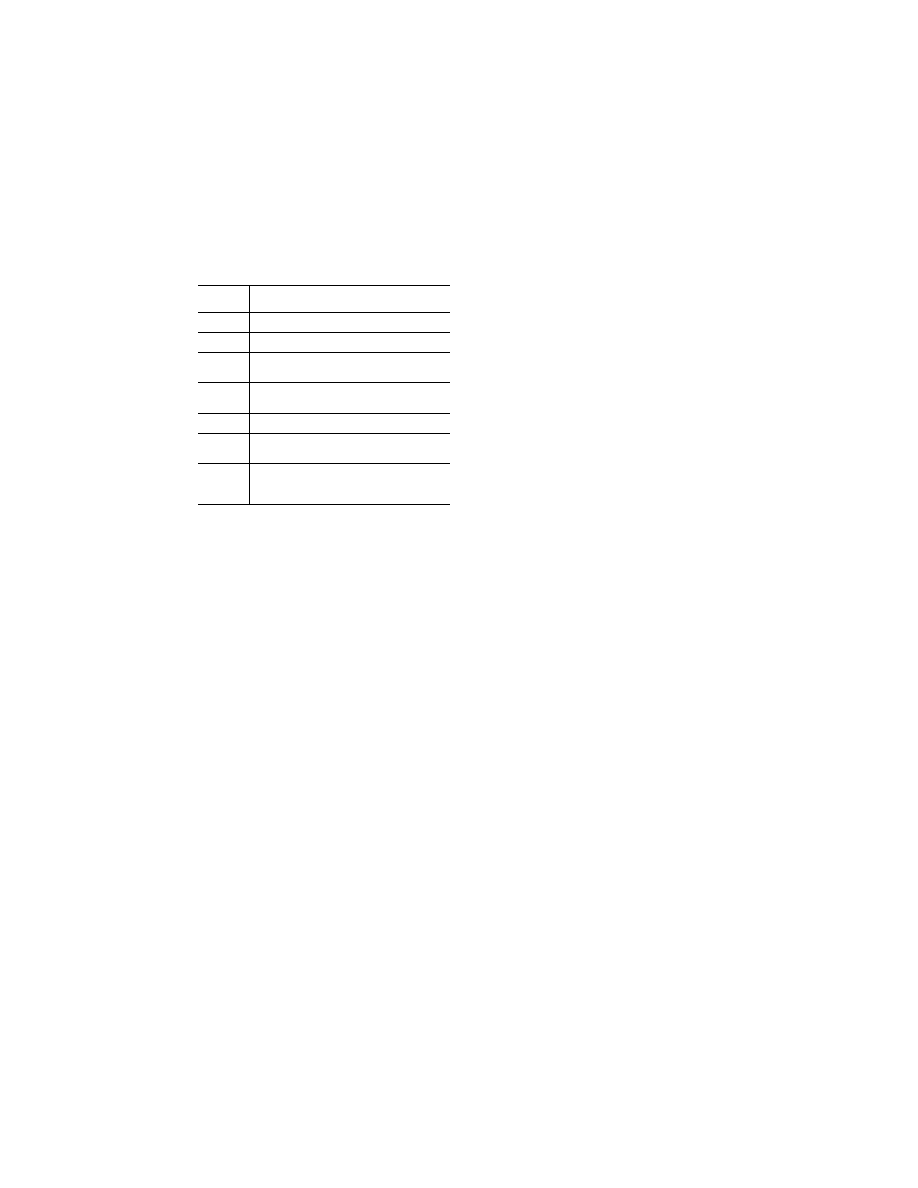

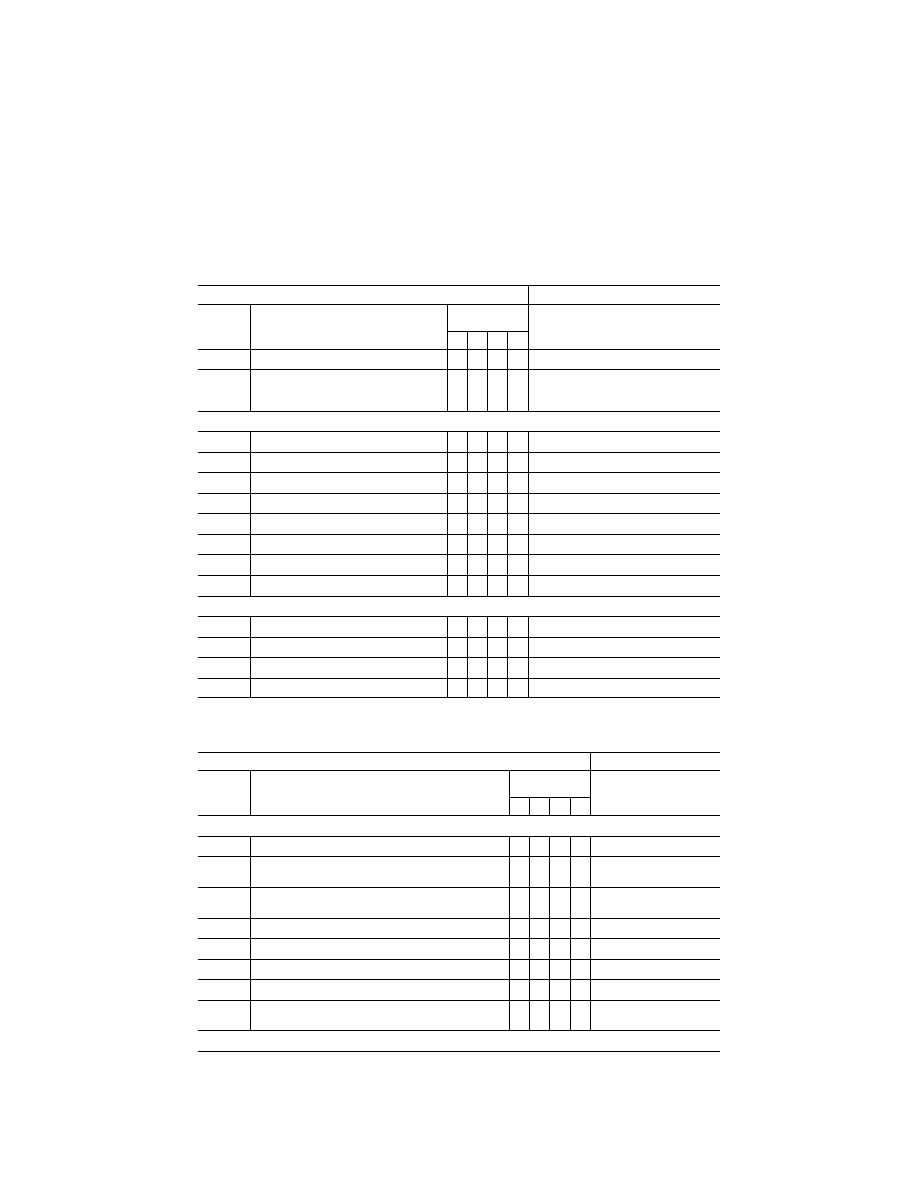

Sec.

60.1

Applicability.

60.2

Applicability of sponsor rules to per-

sons who are not sponsors and who are

engaged in certain unauthorized activi-

ties.

60.3

Definitions.

60.4

Qualification Performance Standards.

60.5

Quality management system.

60.7

Sponsor qualification requirements.

60.9

Additional responsibilities of the spon-

sor.

60.11

FSTD use.

60.13

FSTD objective data requirements.

60.14

Special equipment and personnel re-

quirements for qualification of the

FSTD.

60.15

Initial qualification requirements.

60.16

Additional qualifications for a cur-

rently qualified FSTD.

60.17

Previously qualified FSTDs.

60.19

Inspection, continuing qualification

evaluation, and maintenance require-

ments.

60.20

Logging FSTD discrepancies.

60.21

Interim qualification of FSTDs for

new aircraft types or models.

60.23

Modifications to FSTDs.

60.25

Operation with missing, malfunc-

tioning, or inoperative components.

60.27

Automatic loss of qualification and

procedures for restoration of qualifica-

tion.

60.29

Other losses of qualification and pro-

cedures for restoration of qualification.

60.31

Recordkeeping and reporting.

60.33

Applications, logbooks, reports, and

records: Fraud, falsification, or incorrect

statements.

60.35

Specific full flight simulator compli-

ance requirements.

60.37

FSTD qualification on the basis of a

Bilateral Aviation Safety Agreement

(BASA).

A

PPENDIX

A

TO

P

ART

60—Q

UALIFICATION

P

ER

-

FORMANCE

S

TANDARDS

FOR

A

IRPLANE

F

ULL

F

LIGHT

S

IMULATORS

A

PPENDIX

B

TO

P

ART

60—Q

UALIFICATION

P

ER

-

FORMANCE

S

TANDARDS

FOR

A

IRPLANE

F

LIGHT

T

RAINING

D

EVICES

A

PPENDIX

C

TO

P

ART

60—Q

UALIFICATION

P

ER

-

FORMANCE

S

TANDARDS

FOR

H

ELICOPTER

F

ULL

F

LIGHT

S

IMULATORS

A

PPENDIX

D

TO

P

ART

60—Q

UALIFICATION

P

ER

-

FORMANCE

S

TANDARDS

FOR

H

ELICOPTER

F

LIGHT

T

RAINING

D

EVICES

A

PPENDIX

E

TO

P

ART

60—Q

UALIFICATION

P

ER

-

FORMANCE

S

TANDARDS FOR

Q

UALITY

M

AN

-

AGEMENT

S

YSTEMS FOR

F

LIGHT

S

IMULA

-

TION

T

RAINING

D

EVICES

A

PPENDIX

F

TO

P

ART

60—D

EFINITIONS AND

A

B

-

BREVIATIONS

FOR

F

LIGHT

S

IMULATION

T

RAINING

D

EVICES

A

UTHORITY

: 49 U.S.C. 106(f), 106(g), 40113,

and 44701; Pub. L. 111–216, 124 Stat. 2348 (49

U.S.C. 44701 note)

S

OURCE

: Docket No. FAA–2002–12461, 71 FR

63426, Oct. 30, 2006, unless otherwise noted.

§ 60.1

Applicability.

(a) This part prescribes the rules gov-

erning the initial and continuing quali-

fication and use of all aircraft flight

simulation training devices (FSTD)

used for meeting training, evaluation,

or flight experience requirements of

this chapter for flight crewmember cer-

tification or qualification.

(b) The rules of this part apply to

each person using or applying to use an

FSTD to meet any requirement of this

chapter.

(c) The requirements of § 60.33 regard-

ing falsification of applications,

records, or reports also apply to each

person who uses an FSTD for training,

evaluation, or obtaining flight experi-

ence required for flight crewmember

certification or qualification under

this chapter.

§ 60.2

Applicability of sponsor rules to

persons who are not sponsors and

who are engaged in certain unau-

thorized activities.

(a) The rules of this part that are di-

rected to a sponsor of an FSTD also

apply to any person who uses or causes

the use of an FSTD when—

(1) That person knows that the FSTD

does not have an FAA-approved spon-

sor; and

(2) The use of the FSTD by that per-

son is nonetheless claimed for purposes

of meeting any requirement of this

chapter or that person knows or should

have known that the person’s acts or

omissions would cause another person

to mistakenly credit use of the FSTD

for purposes of meeting any require-

ment of this chapter.

VerDate Sep<11>2014

14:00 Mar 14, 2024

Jkt 262047

PO 00000

Frm 00015

Fmt 8010

Sfmt 8010

Q:\14\14V2.TXT

PC31

aworley on LAPBH6H6L3 with DISTILLER

6

14 CFR Ch. I (1–1–24 Edition)

§ 60.3

(b) A situation in which paragraph

(a) of this section would not apply to a

person would be when each of the fol-

lowing conditions are met:

(1) The person sold or leased the

FSTD and merely represented to the

purchaser or lessee that the FSTD is in

a condition in which it should be able

to obtain FAA approval and qualifica-

tion under this part;

(2) The person does not falsely claim

to be the FAA-approved sponsor for the

FSTD;

(3) The person does not falsely make

representations that someone else is

the FAA-approved sponsor of the FSTD

at a time when that other person is not

the FAA-approved sponsor of the

FSTD; and

(4) The person’s acts or omissions do

not cause another person to detrimen-

tally rely on such acts or omissions for

the mistaken conclusion that the

FSTD is FAA-approved and qualified

under this part at the time the FSTD

is sold or leased.

§ 60.3

Definitions.

In addition to the definitions in part

1 of this chapter, other terms and defi-

nitions applicable to this part are

found in appendix F of this part.

§ 60.4

Qualification Performance

Standards.

The Qualification Performance

Standards (QPS) are published in ap-

pendices to this part as follows:

(a) Appendix A contains the QPS for

Airplane Flight Simulators.

(b) Appendix B contains the QPS for

Airplane Flight Training Devices.

(c) Appendix C contains the QPS for

Helicopter Flight Simulators.

(d) Appendix D contains the QPS for

Helicopter Flight Training Devices.

(e) Appendix E contains the QPS for

Quality Management Systems for

FSTDs.

(f) Appendix F contains the QPS for

Definitions and Abbreviations for

FSTDs.

§ 60.5

Quality management system.

(a) After May 30, 2010, no sponsor

may use or allow the use of or offer the

use of an FSTD for flight crewmember

training or evaluation or for obtaining

flight experience to meet any require-

ment of this chapter unless the sponsor

has established and follows a quality

management system (QMS), currently

approved by the responsible Flight

Standards office, for the continuing

surveillance and analysis of the spon-

sor’s performance and effectiveness in

providing a satisfactory FSTD for use

on a regular basis as described in QPS

appendix E of this part.

(b) The QMS program must provide a

process for identifying deficiencies in

the program and for documenting how

the program will be changed to address

these deficiencies.

(c) Whenever the responsible Flight

Standards office finds that the QMS

program does not adequately address

the procedures necessary to meet the

requirements of this part, the sponsor

must, after notification by the respon-

sible Flight Standards office, change

the program so the procedures meet

the requirements of this part. Each

such change must be approved by the

responsible Flight Standards office

prior to implementation.

(d) Within 30 days after the sponsor

receives a notice described in para-

graph (c) of this section, the sponsor

may file a petition with the Executive

Director of Flight Standards Service

(the Executive Director) for reconsider-

ation of the responsible Flight Stand-

ards office finding. The sponsor must

address its petition to the Executive

Director, Flight Standards Service,

Federal Aviation Administration, 800

Independence Ave., SW., Washington,

DC 20591. The filing of such a petition

to reconsider stays the notice pending

a decision by the Executive Director.

However, if the Executive Director

finds that there is a situation that re-

quires immediate action in the interest

of safety in air commerce, he may,

upon a statement of the reasons, re-

quire a change effective without stay.

[Doc. No. FAA–2002–12461, 71 FR 63426, Oct.

30, 2006; Amdt. 60–2, 72 FR 59599, Oct. 22, 2007,

as amended by Docket FAA–2018–0119, Amdt.

60–5, 83 FR 9170, Mar. 5, 2018; Docket No.

FAA–2022–1355; Amdt. No. 60–7, 87 FR 75711,

Dec. 9, 2022]

VerDate Sep<11>2014

14:00 Mar 14, 2024

Jkt 262047

PO 00000

Frm 00016

Fmt 8010

Sfmt 8010

Q:\14\14V2.TXT

PC31

aworley on LAPBH6H6L3 with DISTILLER

7

Federal Aviation Administration, DOT

§ 60.7

§ 60.7

Sponsor qualification require-

ments.

(a) A person is eligible to apply to be

a sponsor of an FSTD if the following

conditions are met:

(1) The person holds, or is an appli-

cant for, a certificate under part 119,

141, or 142 of this chapter; or holds, or

is an applicant for, an approved flight

engineer course in accordance with

part 63 of this chapter.

(2) The FSTD will be used, or will be

offered for use, in the sponsor’s FAA-

approved flight training program for

the aircraft being simulated as evi-

denced in a request for evaluation sub-

mitted to the responsible Flight Stand-

ards office.

(b) A person is a sponsor if the fol-

lowing conditions are met:

(1) The person is a certificate holder

under part 119, 141, or 142 of this chap-

ter or has an approved flight engineer

course in accordance with part 63 of

this chapter.

(2) The person has—

(i) Operations specifications author-

izing the use of the specific aircraft or

set of aircraft and has an FAA-ap-

proved training program under which

at least one FSTD, simulating the air-

craft or set of aircraft and for which

the person is the sponsor, is used by

the sponsor as described in paragraphs

(b)(5) or (b)(6) of this section; or

(ii) Training specifications or an

FAA-approved course of training under

which at least one FSTD, simulating

that aircraft or set of aircraft and for

which the person is the sponsor, is used

by the sponsor as described in para-

graphs (b)(5) or (b)(6) of this section.

(3) The person has a quality manage-

ment system currently approved by the

responsible Flight Standards office in

accordance with § 60.5.

(4) The responsible Flight Standards

office has accepted the person as the

sponsor of the FSTD and that accept-

ance has not been withdrawn by the

FAA.

(5) At least one FSTD (as referenced

in paragraph (b)(2)(i) or (b)(2)(ii) of this

section) that is initially qualified on or

after May 30, 2008, is used within the

sponsor’s FAA-approved flight training

program for the aircraft or set of air-

craft at least once within the 12-month

period following the initial/upgrade

evaluation, and at least once within

each subsequent 12-month period there-

after.

(6) At least one FSTD (as referenced

in paragraph (b)(2)(i) or (b)(2)(ii) of this

section) that was qualified before May

30, 2008, is used within the sponsor’s

FAA-approved flight training program

for the aircraft or set of aircraft at

least once within the 12-month period

following the first continuing quali-

fication evaluation conducted by the

responsible Flight Standards office

after May 30, 2008 and at least once

within each subsequent 12-month pe-

riod thereafter.

(c) If the use requirements of para-

graphs (b)(2) and either (b)(5) or (b)(6)

of this section are not met, the person

will forfeit the right to sponsor that

FSTD and that person will not be eligi-

ble to apply to sponsor that FSTD for

at least 12 calendar months following

the expiration of the qualification sta-

tus.

(d) In addition to the FSTD described

in paragraph (b) of this section, an

FSTD sponsor may sponsor any num-

ber of other FSTDs regardless of spe-

cific aircraft or set of aircraft provided

either—

(1) During the preceding 12-month pe-

riod, all of the other FSTDs are used

within the sponsor’s or another certifi-

cate holder’s FAA-approved flight

training program for the aircraft or set

of aircraft simulated; or

(2) The sponsor obtains a written

statement at least annually from a

qualified pilot who has flown the air-

craft or set of aircraft (as appropriate)

during the preceding 12-month period

stating that the subject FSTD’s per-

formance and handling qualities, with-

in the normal operating envelope, rep-

resent the aircraft or set of aircraft de-

scribed in the FAA Type Certificate

and the type data sheet, if appropriate.

The sponsor must retain the two most

current written statements for review

by the responsible Flight Standards of-

fice.

[Doc. No. FAA–2002–12461, 71 FR 63426, Oct.

30, 2006; Amdt. 60–2, 72 FR 59599, Oct. 22, 2007,

as amended by Docket No. FAA–2022–1355,

Amdt. No. 60–7, 87 FR 75711, Dec. 9, 2022]

VerDate Sep<11>2014

14:00 Mar 14, 2024

Jkt 262047

PO 00000

Frm 00017

Fmt 8010

Sfmt 8010

Q:\14\14V2.TXT

PC31

aworley on LAPBH6H6L3 with DISTILLER

8

14 CFR Ch. I (1–1–24 Edition)

§ 60.9

§ 60.9

Additional responsibilities of the

sponsor.

(a) The sponsor must allow the re-

sponsible Flight Standards office upon

request to inspect the FSTD as soon as

practicable. This inspection may in-

clude all records and documents relat-

ing to the FSTD, to determine its com-

pliance with this part.

(b) The sponsor must do the following

for each FSTD:

(1) Establish a mechanism to receive

written comments regarding the FSTD

and its operation in accordance with

the QPS appendix E of this part.

(2) Post in or adjacent to the FSTD

the Statement of Qualification issued

by the responsible Flight Standards of-

fice. An electronic copy of the State-

ment of Qualification that may be

accessed by an appropriate terminal or

display in or adjacent to the FSTD is

satisfactory.

(c) Each sponsor of an FSTD must

identify to the responsible Flight

Standards office by name, one indi-

vidual to be the management rep-

resentative (MR).

(1) One person may serve as an MR

for more than one FSTD, but one

FSTD must not have more than one

person serving in this capacity.

(2) Each MR must be an employee of

the sponsor with the responsibility and

authority to—

(i) Monitor the on-going qualification

of assigned FSTDs to ensure that all

matters regarding FSTD qualification

are being carried out as provided for in

this part;

(ii) Ensure that the QMS is properly

established, implemented, and main-

tained by overseeing the structure (and

modifying where necessary) of the QMS

policies, practices, and procedures; and

(iii) Regularly brief sponsor’s man-

agement on the status of the on-going

FSTD qualification program and the

effectiveness and efficiency of the

QMS.

(3) The MR serves as the primary

contact point for all matters between

the sponsor and the responsible Flight

Standards office regarding the quali-

fication of that FSTD as provided for

in this part.

(4) The MR may delegate the duties

described in paragraph (c)(2) and (c)(3)

of this section to an individual at each

of the sponsor’s locations.

[Docket No. FAA–2002–12461, 71 FR 63426, Oct.

30, 2006, as amended by Docket No. FAA–

2022–1355, Amdt. No. 60–7, 87 FR 75711, Dec. 9,

2022]

§ 60.11

FSTD use.

No person may use or allow the use

of or offer the use of an FSTD for flight

crewmember training or evaluation or

for obtaining flight experience to meet

any of the requirements under this

chapter unless, in accordance with the

QPS for the specific device, the FSTD

meets all of the following:

(a) Has a single sponsor who is quali-

fied under § 60.7. The sponsor may ar-

range with another person for services

of document preparation and presen-

tation, as well as FSTD inspection,

maintenance, repair, and servicing;

however, the sponsor remains respon-

sible for ensuring that these functions

are conducted in a manner and with a

result of continually meeting the re-

quirements of this part.

(b) Is qualified as described in the

Statement of Qualification.

(c) Remains qualified, through satis-

factory inspection, continuing quali-

fication evaluations, appropriate main-

tenance, and use requirements in ac-

cordance with this part and the appli-

cable QPS.

(d) Functions during day-to-day

training, evaluation, or flight experi-

ence activities with the software and

hardware that was evaluated as satis-

factory by the responsible Flight

Standards office and, if modified, modi-

fied only in accordance with the provi-

sions of this part. However, this sec-

tion does not apply to routine software

or hardware changes that do not fall

under the requirements of § 60.23.

(e) Is operated in accordance with the

provisions and limitations of § 60.25.

[Docket No. FAA–2002–12461, 71 FR 63426, Oct.

30, 2006, as amended by Docket No. FAA–

2022–1355, Amdt. No. 60–7, 87 FR 75711, Dec. 9,

2022]

§ 60.13

FSTD objective data require-

ments.

(a) Except as provided in paragraph

(b) and (c) of this section, for the pur-

poses of validating FSTD performance

VerDate Sep<11>2014

14:00 Mar 14, 2024

Jkt 262047

PO 00000

Frm 00018

Fmt 8010

Sfmt 8010

Q:\14\14V2.TXT

PC31

aworley on LAPBH6H6L3 with DISTILLER

9

Federal Aviation Administration, DOT

§ 60.15

and handling qualities during evalua-

tion for qualification, the data made

available to the responsible Flight

Standards office (the validation data

package) must include the aircraft

manufacturer’s flight test data and all

relevant data developed after the type

certificate was issued (

e.g., data devel-

oped in response to an airworthiness

directive) if such data results from a

change in performance, handling quali-

ties, functions, or other characteristics

of the aircraft that must be considered

for flight crewmember training, eval-

uation, or for meeting experience re-

quirements of this chapter.

(b) The validation data package may

contain flight test data from a source

in addition to or independent of the

aircraft manufacturer’s data in support

of an FSTD qualification, but only if

this data is gathered and developed by

that source in accordance with flight

test methods, including a flight test

plan, as described in the applicable

QPS.

(c) The validation data package may

also contain predicted data, engineer-

ing simulation data, data from pilot

owner or pilot operating manuals, or

data from public domain sources, pro-

vided this data is acceptable to the re-

sponsible Flight Standards office. If

found acceptable the data may then be

used in particular applications for

FSTD qualification.

(d) Data or other material or ele-

ments must be submitted in a form and

manner acceptable to the responsible

Flight Standards office.

(e) The responsible Flight Standards

office may require additional objective

data, which may include flight testing

if necessary, if the validation data

package does not support FSTD quali-

fication requirements as described in

this part and the applicable QPS ap-

pendix.

(f) When an FSTD sponsor learns, or

is advised by an aircraft manufacturer

or other data provider, that an addi-

tion to, an amendment to, or a revision

of data that may relate to FSTD per-

formance or handling characteristics is

available, the sponsor must notify the

responsible Flight Standards office as

described in the applicable QPS.

[Docket No. FAA–2002–12461, 71 FR 63426, Oct.

30, 2006, as amended by Docket No. FAA–

2022–1355, Amdt. No. 60–7, 87 FR 75711, Dec. 9,

2022]

§ 60.14

Special equipment and per-

sonnel requirements for qualifica-

tion of the FSTD.

When notified by the responsible

Flight Standards office, the sponsor

must make available all special equip-

ment and qualified personnel needed to

accomplish or assist in the accomplish-

ment of tests during initial qualifica-

tion, continuing qualification, or spe-

cial evaluations.

[Docket No. FAA–2002–12461, 71 FR 63426, Oct.

30, 2006, as amended by Docket No. FAA–

2022–1355, Amdt. No. 60–7, 87 FR 75711, Dec. 9,

2022]

§ 60.15

Initial qualification require-

ments.

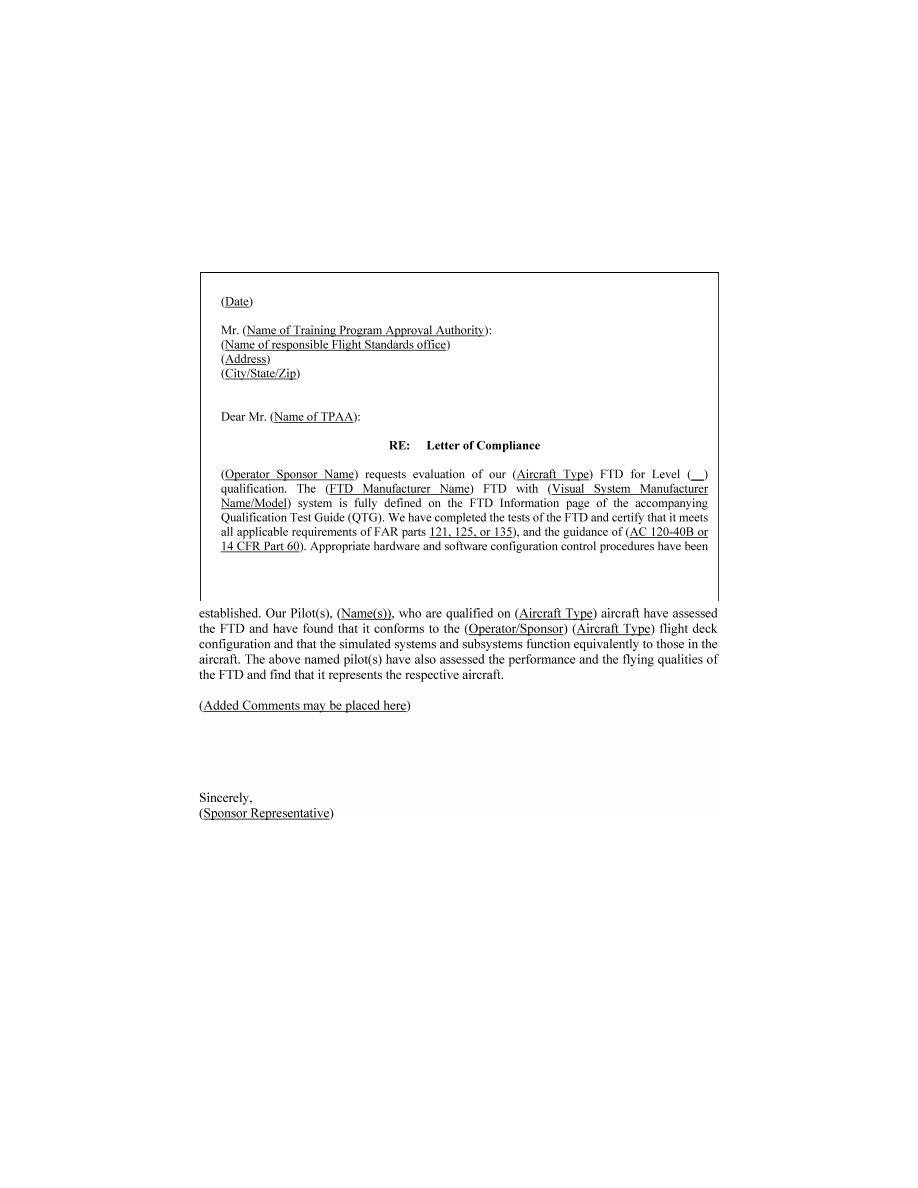

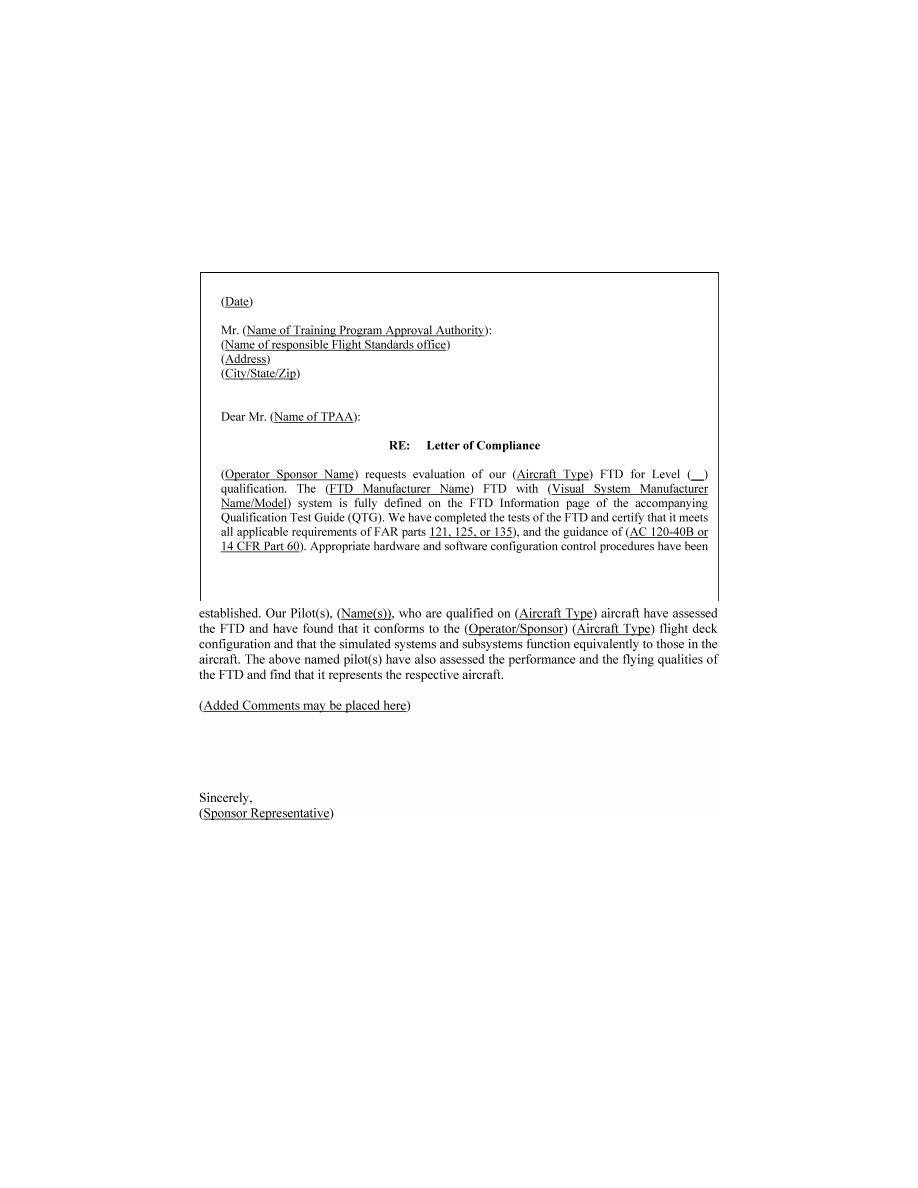

(a) For each FSTD, the sponsor must

submit a request to the responsible

Flight Standards office to evaluate the

FSTD for initial qualification at a spe-

cific level and simultaneously request

the Training Program Approval Au-

thority (TPAA) forward a concurring

letter to the responsible Flight Stand-

ards office. The request must be sub-

mitted in the form and manner de-

scribed in the applicable QPS.

(b) The management representative

described in § 60.9(c) must sign a state-

ment (electronic signature is accept-

able for electronic transmissions) after

confirming the following:

(1) The performance and handling

qualities of the FSTD represent those

of the aircraft or set of aircraft within

the normal operating envelope. This

determination must be made by a

pilot(s) meeting the requirements of

paragraph (d) of this section after hav-

ing flown all of the Operations Tasks

listed in the applicable QPS appendix

relevant to the qualification level of

the FSTD. Exceptions, if any, must be

noted. The name of the person(s) mak-

ing this determination must be avail-

able to the responsible Flight Stand-

ards office upon request.

(2) The FSTD systems and sub-sys-

tems (including the simulated aircraft

systems) functionally represent those

VerDate Sep<11>2014

14:00 Mar 14, 2024

Jkt 262047

PO 00000

Frm 00019

Fmt 8010

Sfmt 8010

Q:\14\14V2.TXT

PC31

aworley on LAPBH6H6L3 with DISTILLER

10

14 CFR Ch. I (1–1–24 Edition)

§ 60.15

in the aircraft or set of aircraft. This

determination must be made by the

pilot(s) described in paragraph (b)(1) of

this section, or by a person(s) trained

on simulator systems/sub-systems and

trained on the operation of the simu-

lated aircraft systems, after having ex-

ercised the operation of the FSTD and

the pertinent functions available

through the Instructor Operating Sta-

tion(s). Exceptions, if any, must be

noted. The name of the person(s) mak-

ing this determination must be avail-

able to the responsible Flight Stand-

ards office upon request.

(3) The cockpit represents the con-

figuration of the specific type; or air-

craft make, model, and series aircraft

being simulated, as appropriate. This

determination must be made by the

pilot(s) described in paragraph (b)(1) of

this section, or by a person(s) trained

on the configuration and operation of

the aircraft simulated. Exceptions, if

any, must be noted. The name of the

person(s) making this determination

must be available to the responsible

Flight Standards office upon request.

(c) Except for those FSTDs pre-

viously qualified and described in

§ 60.17, each FSTD evaluated for initial

qualification must meet the standard

that is in effect at the time of the eval-

uation. However—

(1) If the FAA publishes a change to

the existing standard or publishes a

new standard for the evaluation for ini-

tial qualification, a sponsor may re-

quest that the responsible Flight

Standards office apply the standard

that was in effect when an FSTD was

ordered for delivery if the sponsor—

(i) Within 30 days of the publication

of the change to the existing standard

or publication of the new standard, no-

tifies the responsible Flight Standards

office that an FSTD has been ordered;

(ii) Within 90 days of the responsible

Flight Standards office notification de-

scribed in paragraph (c)(1)(i) of this

section, requests that the standard in

effect at the time the order was placed

be used for the evaluation for initial

qualification; and

(iii) The evaluation is conducted

within 24 months following the publica-

tion of the change to the existing

standard or publication of the new

standard.

(2) This notification must include a

description of the FSTD; the antici-

pated qualification level of the FSTD;

the make, model, and series of aircraft

simulated; and any other pertinent in-

formation.

(3) Any tests, tolerances, or other re-

quirements that are current at the

time of the evaluation may be used

during the initial evaluation, at the re-

quest of the sponsor, if the sponsor pro-

vides acceptable updates to the re-

quired qualification test guide.

(4) The standards used for the evalua-

tion for initial qualification will be

used for all subsequent evaluations of

the FSTD.

(5) An FSTD sponsor or FSTD manu-

facturer may submit a request to the

Administrator for approval of a devi-

ation from the QPS requirements as

defined in Appendix A through Appen-

dix D of this part.

(i) Requests for deviation must be

submitted in a form and manner ac-

ceptable to the Administrator and

must provide sufficient justification

that the deviation meets or exceeds the

testing requirements and tolerances as

specified in the part 60 QPS or will oth-

erwise not adversely affect the fidelity

and capability of the FSTDs evaluated

and qualified under the deviation.

(ii) The Administrator may consider

deviation from the minimum require-

ments tables, the objective testing ta-

bles, the functions and subjective test-

ing tables, and other supporting tables

and requirements in the part 60 QPS.

(iii) Deviations may be issued to an

FSTD manufacturer for the initial

qualification of multiple FSTDs, sub-

ject to terms and limitations as deter-

mined by Administrator. Approved de-

viations will become a part of the per-

manent qualification basis of the indi-

vidual FSTD and will be noted in the

FSTD’s Statement of Qualification.

(iv) If the FAA publishes a change to

the existing part 60 standards as de-

scribed in paragraph (c)(1) of this sec-

tion or issues an FSTD Directive as de-

scribed in § 60.23(b), which conflicts

with or supersedes an approved devi-

ation, the Administrator may termi-

nate or revise a grant of deviation au-

thority issued under this paragraph.

VerDate Sep<11>2014

14:00 Mar 14, 2024

Jkt 262047

PO 00000

Frm 00020

Fmt 8010

Sfmt 8010

Q:\14\14V2.TXT

PC31

aworley on LAPBH6H6L3 with DISTILLER

11

Federal Aviation Administration, DOT

§ 60.16

(d) The pilot(s) who contributes to

the confirmation statement required

by paragraph (b) of this section must—

(1) Be designated by the sponsor; and

(2) Be qualified in—

(i) The aircraft or set of aircraft

being simulated; or

(ii) For aircraft not yet issued a type

certificate, or aircraft not previously

operated by the sponsor or not having

previous FAA-approved training pro-

grams conducted by the sponsor, an

aircraft similar in size and configura-

tion.

(e) The subjective tests that form the

basis for the statements described in

paragraph (b) of this section and the

objective tests referenced in paragraph

(f) of this section must be accom-

plished at the sponsor’s training facil-

ity or other sponsor designated loca-

tion where training will take place, ex-

cept as provided for in the applicable

QPS.

(f) The person seeking to qualify the

FSTD must provide the responsible

Flight Standards office access to the

FSTD for the length of time necessary

for the responsible Flight Standards of-

fice to complete the required evalua-

tion of the FSTD for initial qualifica-

tion, which includes the conduct and

evaluation of objective and subjective

tests, including general FSTD require-

ments, as described in the applicable

QPS, to determine that the FSTD

meets the standards in that QPS.

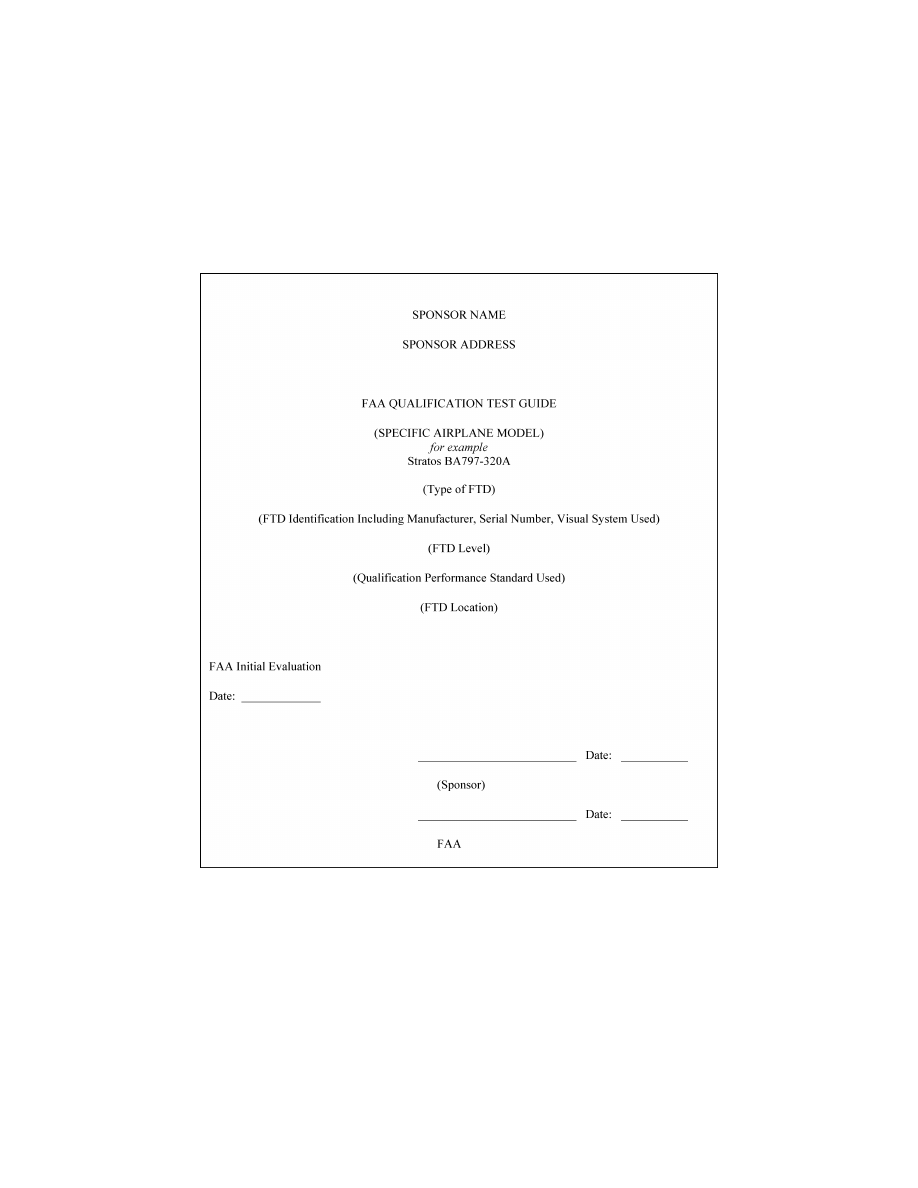

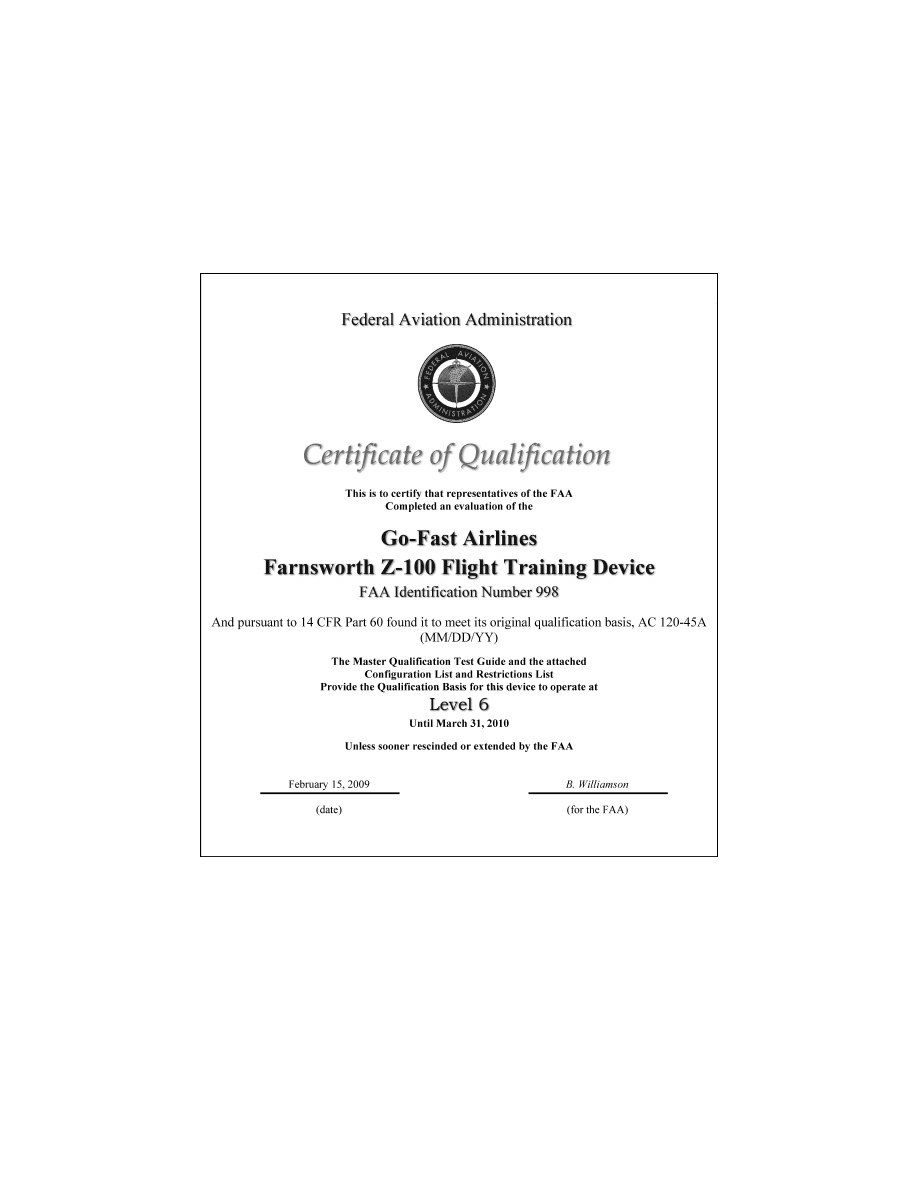

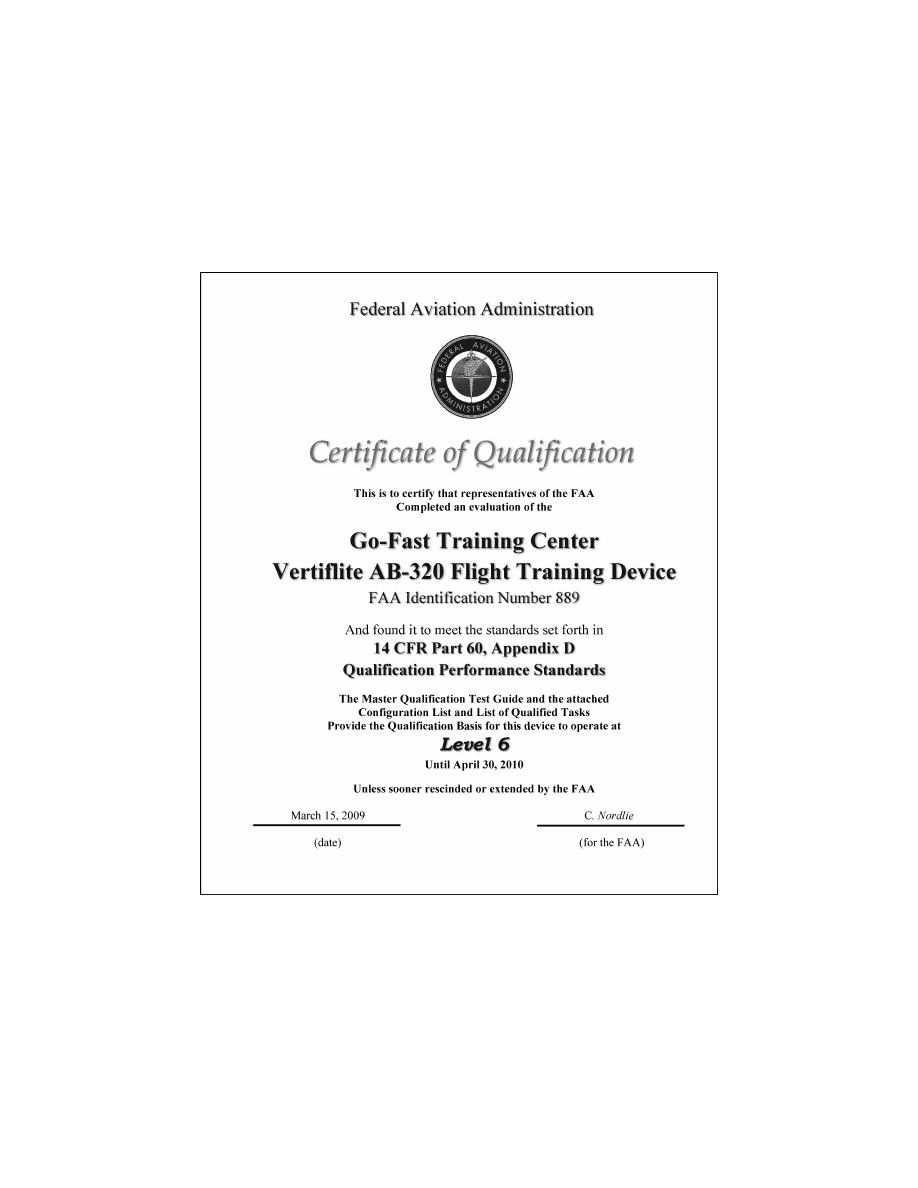

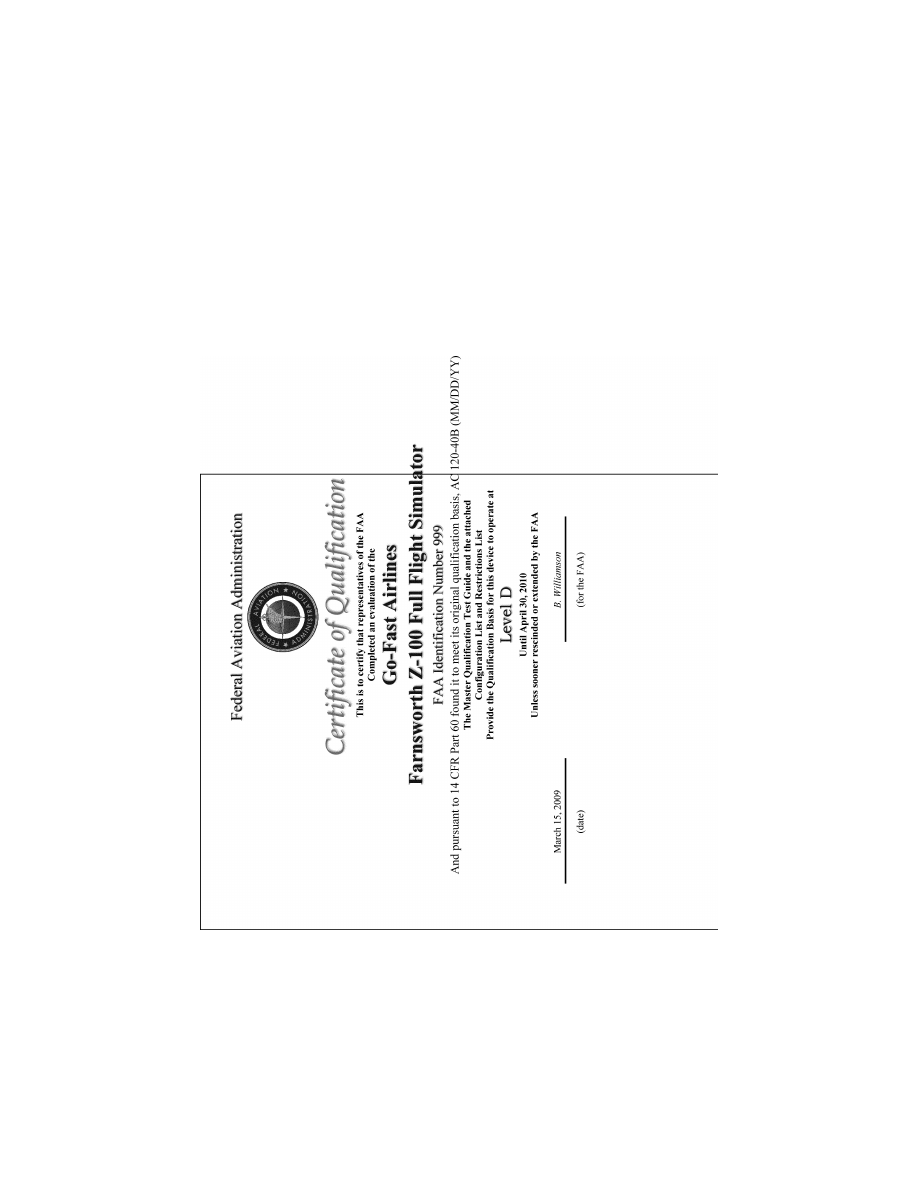

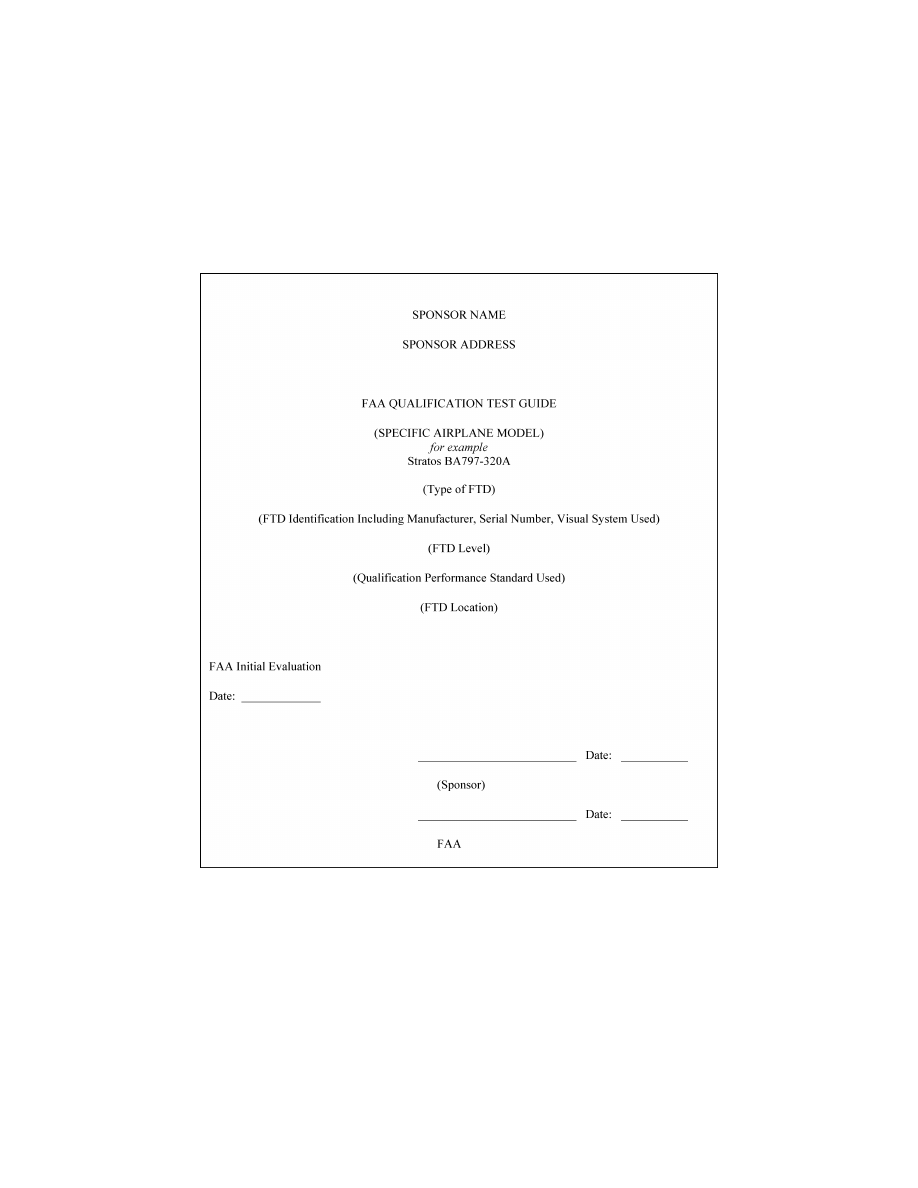

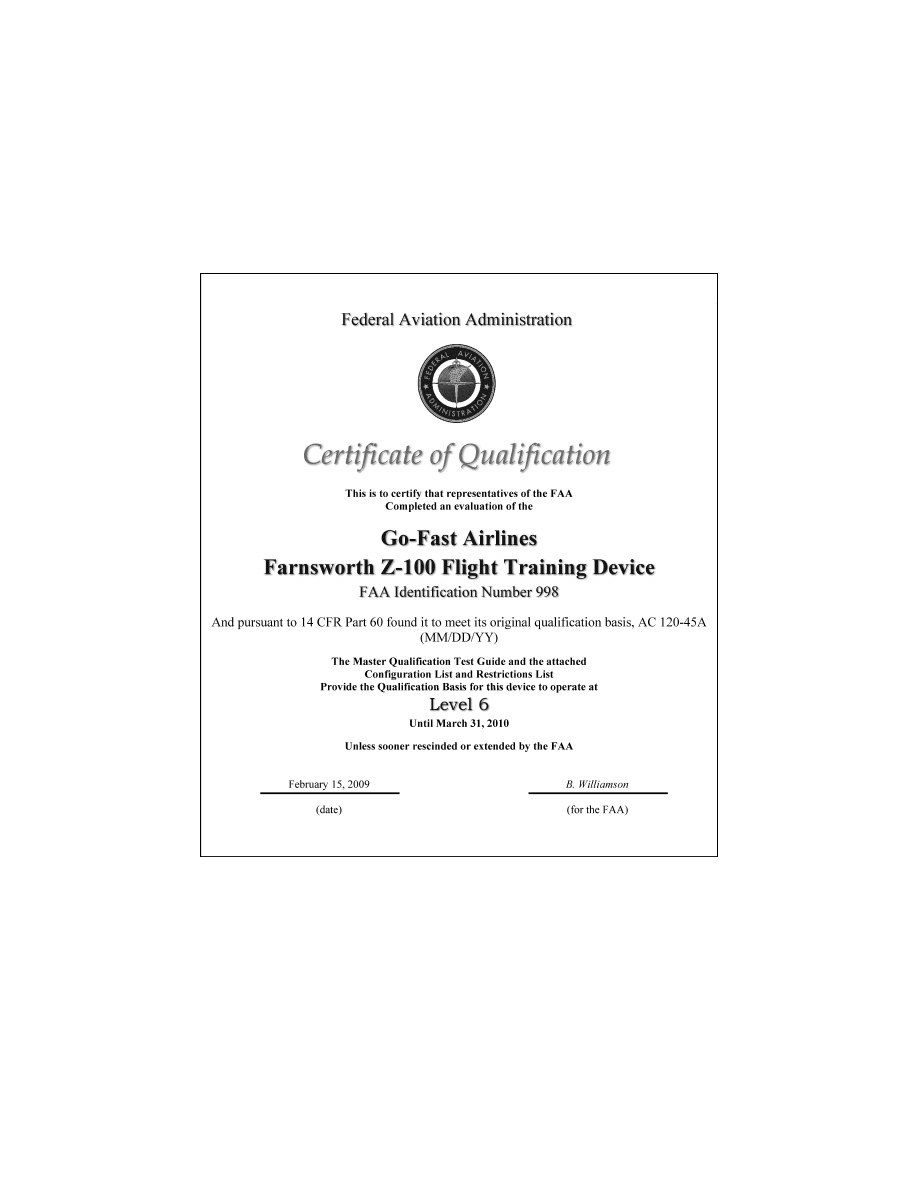

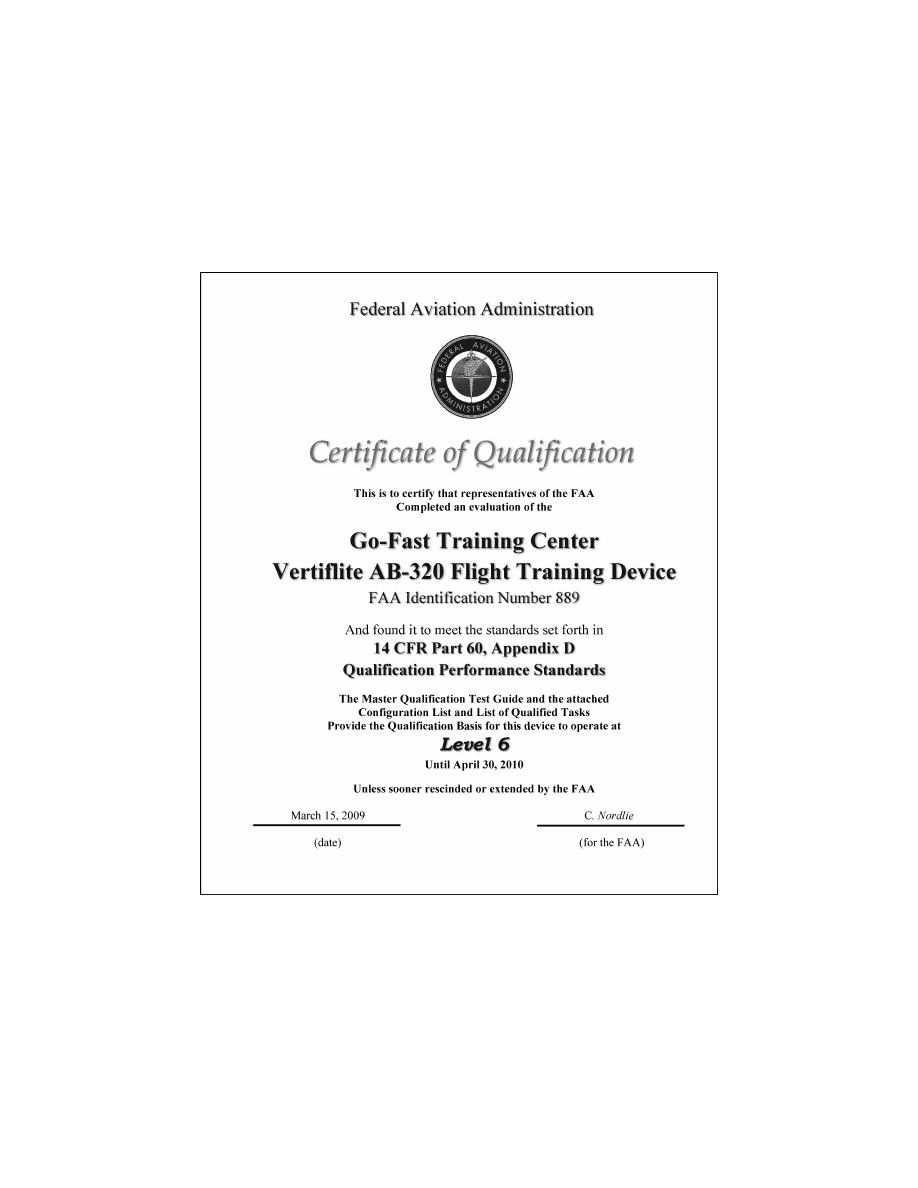

(g) When the FSTD passes an evalua-

tion for initial qualification, the re-

sponsible Flight Standards office issues

a Statement of Qualification that in-

cludes all of the following:

(1) Identification of the sponsor.

(2) Identification of the make, model,

and series of the aircraft or set of air-

craft being simulated.

(3) Identification of the configuration

of the aircraft or set of aircraft being

simulated (

e.g., engine model or mod-

els, flight instruments, or navigation

or other systems).

(4) A statement that the FSTD is

qualified as either a full flight simu-

lator or a flight training device.

(5) Identification of the qualification

level of the FSTD.

(6) A statement that (with the excep-

tion of the noted exclusions for which

the FSTD has not been subjectively

tested by the sponsor or the respon-

sible Flight Standards office and for

which qualification is not sought) the

qualification of the FSTD includes the

tasks set out in the applicable QPS ap-

pendix relevant to the qualification

level of the FSTD.

(7) A statement referencing any devi-

ations that have been granted and in-

cluded in the permanent qualification

basis of the FSTD.

(h) After the responsible Flight

Standards office completes the evalua-

tion for initial qualification, the spon-

sor must update the Qualification Test

Guide (QTG), with the results of the

FAA-witnessed tests together with the

results of all the objective tests de-

scribed in the applicable QPS.

(i) Upon issuance of the Statement of

Qualification the updated QTG be-

comes the Master Qualification Test

Guide (MQTG). The MQTG must be

made available to the responsible

Flight Standards office upon request.

[Docket No. FAA–2002–12461, 71 FR 63426, Oct.

30, 2006, as amended by Docket FAA–2014–

0391, Amdt. 60–4, 81 FR 18217, Mar. 30, 2016;

Docket No. FAA–2022–1355, Amdt. No. 60–7, 87

FR 75711, Dec. 9, 2022]

§ 60.16

Additional qualifications for a

currently qualified FSTD.

(a) A currently qualified FSTD is re-

quired to undergo an additional quali-

fication process if a user intends to use

the FSTD for meeting training, evalua-

tion, or flight experience requirements

of this chapter beyond the qualifica-

tion issued for that FSTD. This process

consists of the following:

(1) The sponsor:

(i) Must submit to the responsible

Flight Standards office all modifica-

tions to the MQTG that are required to

support the additional qualification.

(ii) Must describe to the responsible

Flight Standards office all modifica-

tions to the FSTD that are required to

support the additional qualification.

(iii) Must submit to the responsible

Flight Standards office a confirmation

statement as described in § 60.15(c) that

a pilot, designated by the sponsor in

accordance with § 60.15(d), has subjec-

tively evaluated the FSTD in those

areas not previously evaluated.

(2) The FSTD must successfully pass

an evaluation—

VerDate Sep<11>2014

14:00 Mar 14, 2024

Jkt 262047

PO 00000

Frm 00021

Fmt 8010

Sfmt 8010

Q:\14\14V2.TXT

PC31

aworley on LAPBH6H6L3 with DISTILLER

12

14 CFR Ch. I (1–1–24 Edition)

§ 60.17

(i) Consisting of all the elements of

an initial evaluation for qualification

in those circumstances where the re-

sponsible Flight Standards office has

determined that all the elements of an

initial evaluation for qualification is

necessary; or

(ii) Consisting of those elements of

an initial evaluation for qualification

designated as necessary by the respon-

sible Flight Standards office.

(b) In making the determinations de-

scribed in paragraph (a)(2) of this sec-

tion, the responsible Flight Standards

office considers factors including the

existing qualification of the FSTD, any

modifications to the FSTD hardware or

software that are involved, and any ad-

ditions or modifications to the MQTG.

(c) The FSTD is qualified for the ad-

ditional uses when the responsible

Flight Standards office issues an

amended Statement of Qualification in

accordance with § 60.15(h).

(d) The sponsor may not modify the

FSTD except as described in § 60.23.

[Docket No. FAA–2002–12461, 71 FR 63426, Oct.

30, 2006, as amended by Docket No. FAA–

2022–1355, Amdt. No. 60–7, 87 FR 75711, Dec. 9,

2022]

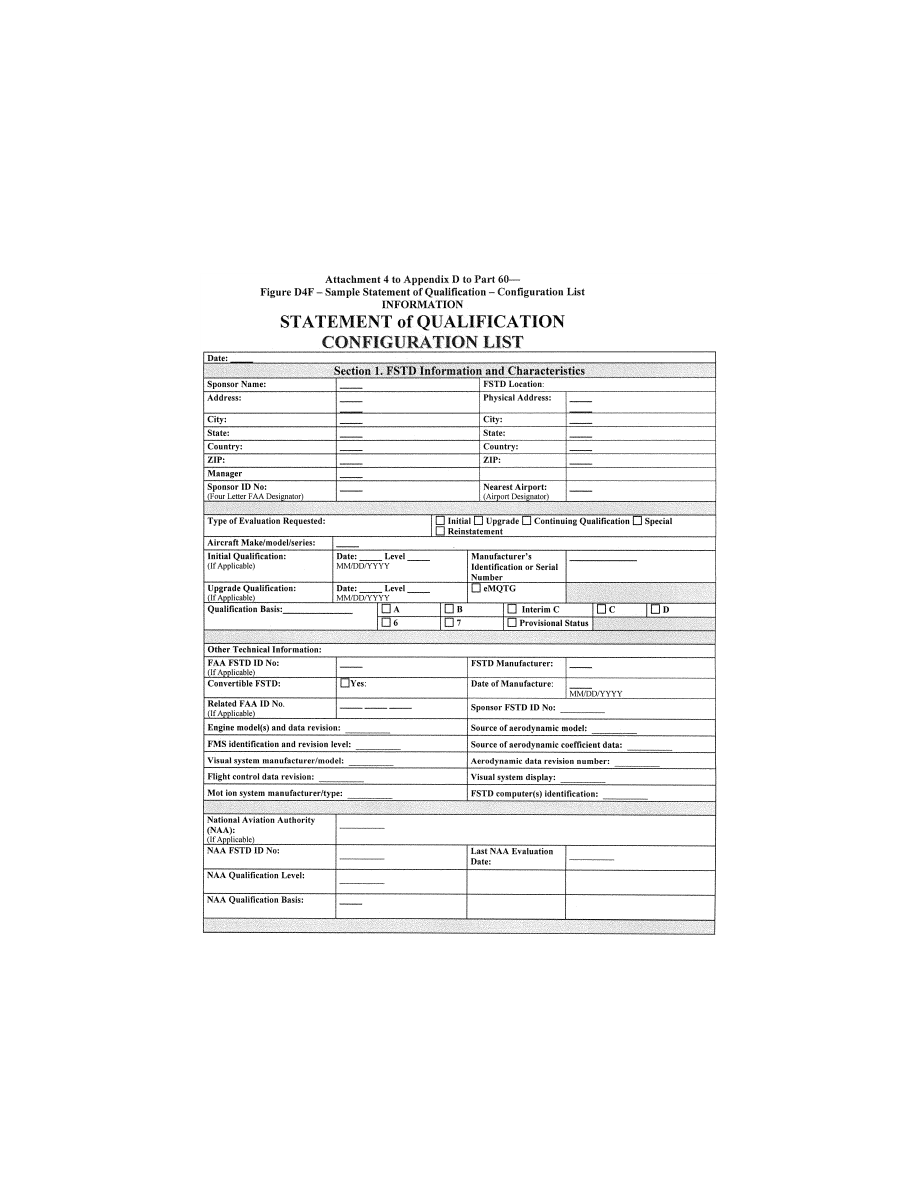

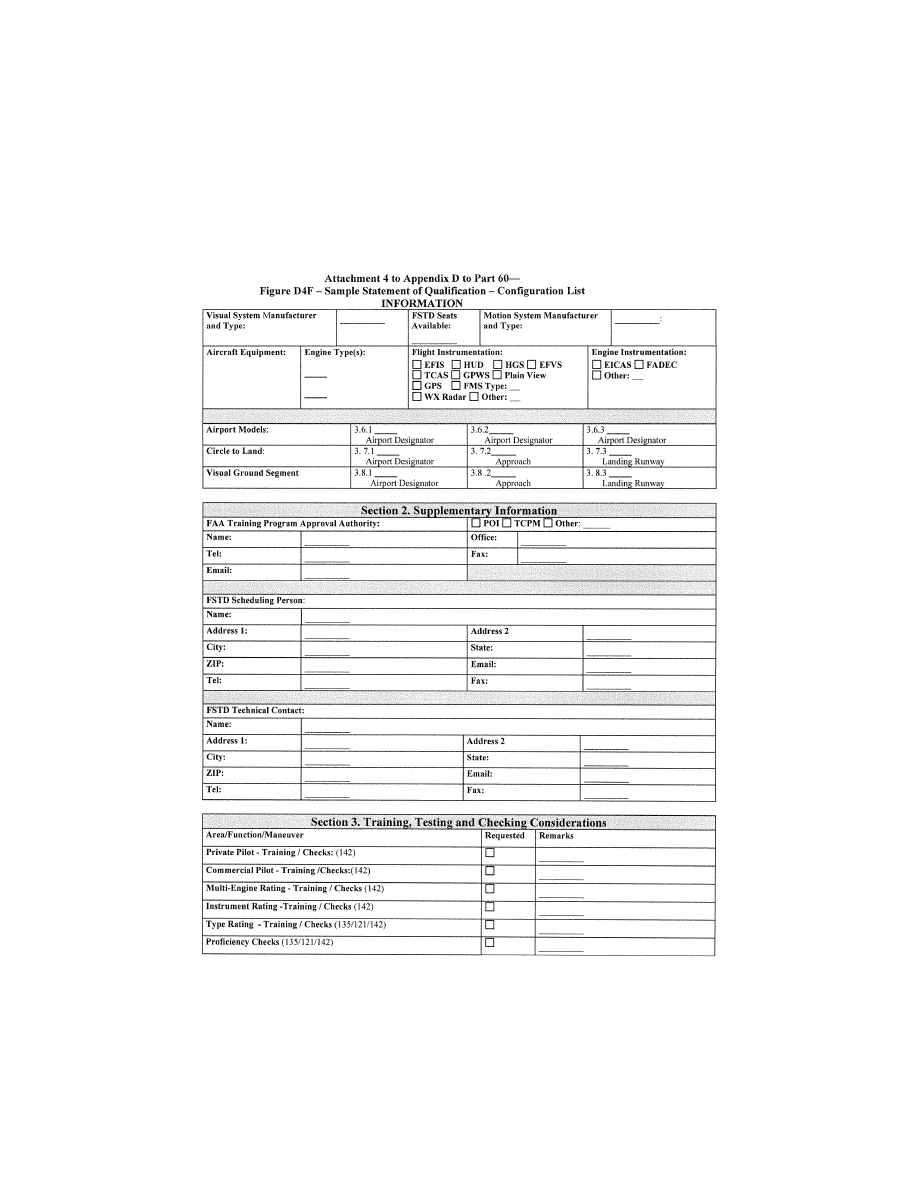

§ 60.17

Previously qualified FSTDs.

(a) Unless otherwise specified by an

FSTD Directive, further referenced in

the applicable QPS, or as specified in

paragraph (e) of this section, an FSTD

qualified before May 31, 2016 will retain

its qualification basis as long as it con-

tinues to meet the standards, including

the objective test results recorded in

the MQTG and subjective tests, under

which it was originally evaluated, re-

gardless of sponsor. The sponsor of

such an FSTD must comply with the

other applicable provisions of this part.

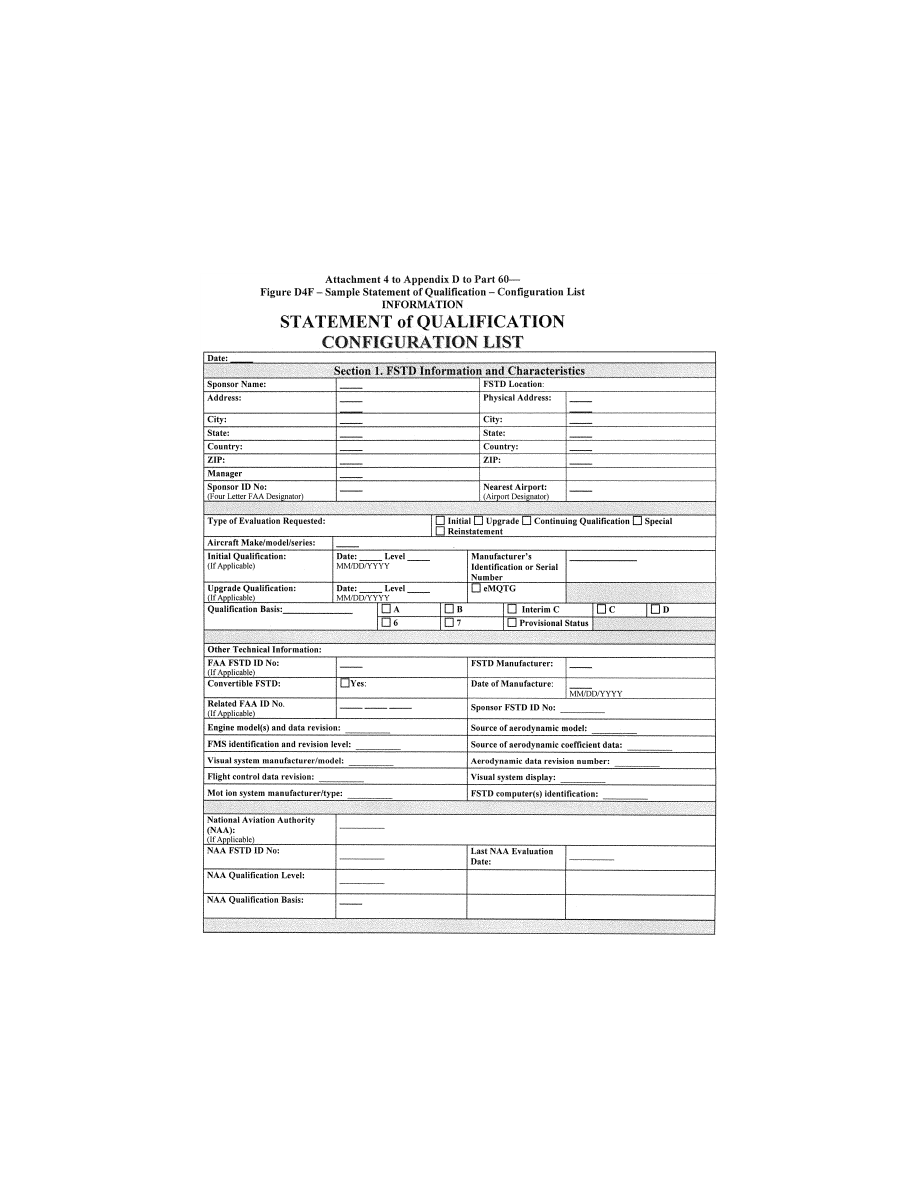

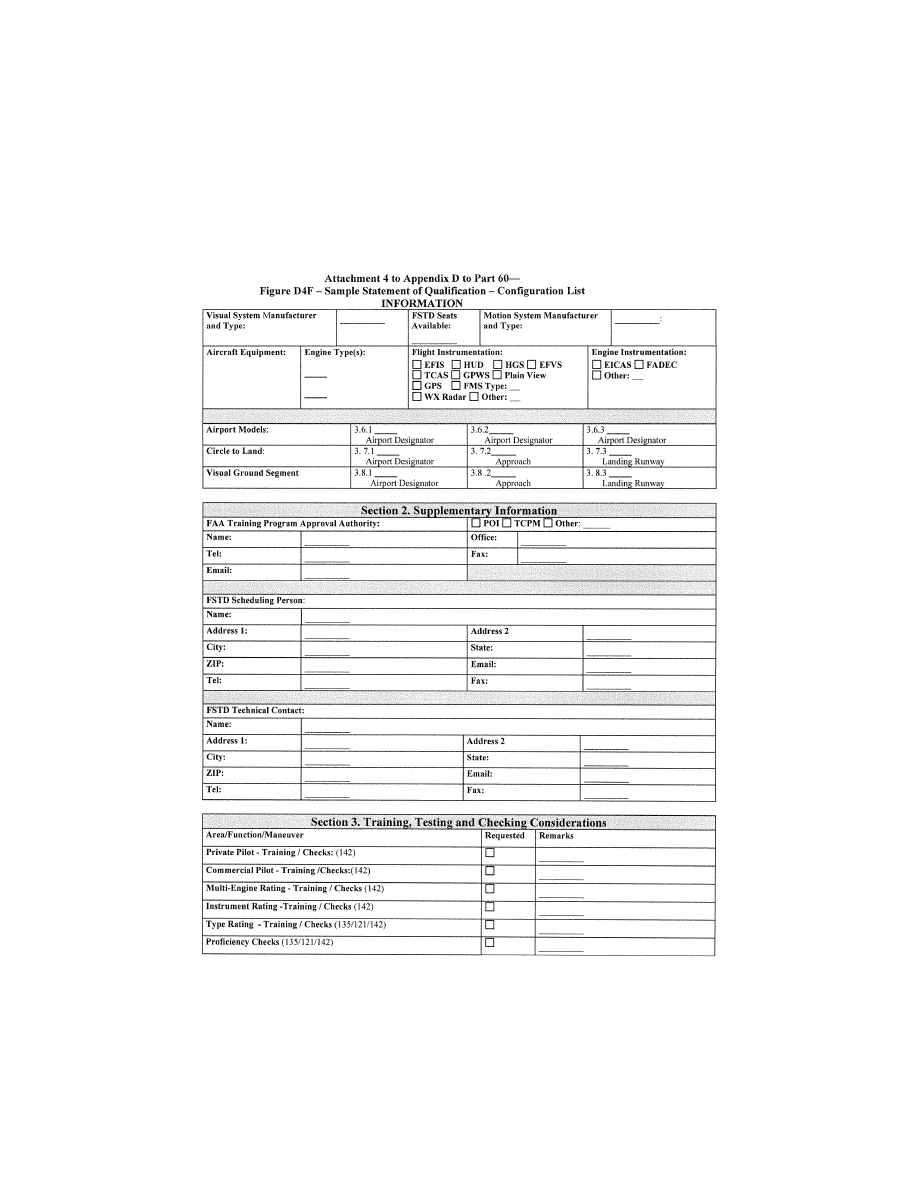

(b) For each FSTD qualified before

May 30, 2008, no sponsor may use or

allow the use of or offer the use of such

an FSTD after May 30, 2014 for flight

crewmember training, evaluation or

flight experience to meet any of the re-

quirements of this chapter, unless that

FSTD has been issued a Statement of

Qualification, including the Configura-

tion List and the List of Qualified

Tasks in accordance with the proce-

dures set out in the applicable QPS.

(c) If the FSTD qualification is lost

under § 60.27 and—

(i) Restored under § 60.27 in less than

(2) years, then the qualification basis

(in terms of objective tests and subjec-

tive tests) for the re-qualification will

be those against which the FSTD was

originally evaluated and qualified.

(ii) Not restored under § 60.27 for two

(2) years or more, then the qualifica-

tion basis (in terms of objective tests

and subjective tests) for the re-quali-

fication will be those standards in ef-

fect and current at the time of re-qual-

ification application.

(d) Except as provided in paragraph

(e) of this section, any change in FSTD

qualification level initiated on or after

May 30, 2008 requires an evaluation for

initial qualification in accordance with

this part.

(e) A sponsor may request that an

FSTD be permanently downgraded. In

such a case, the responsible Flight

Standards office may downgrade a

qualified FSTD without requiring and

without conducting an initial evalua-

tion for the new qualification level.

Subsequent continuing qualification

evaluations will use the existing

MQTG, modified as necessary to reflect

the new qualification level.

(f) When the sponsor has appropriate

validation data available and receives

approval from the responsible Flight

Standards office, the sponsor may

adopt tests and associated tolerances

described in the current qualification

standards as the tests and tolerances

applicable for the continuing qualifica-

tion of a previously qualified FSTD.

The updated test(s) and tolerance(s)

must be made a permanent part of the

MQTG.

[Doc. No. FAA–2002–12461, 71 FR 63426, Oct.

30, 2006; Amdt. 60–2, 72 FR 59599, Oct. 22, 2007,

as amended by Docket FAA–2014–0391, Amdt.

60–4, 81 FR 18218, Mar. 30, 2016; Docket No.

FAA–2022–1355, Amdt. No. 60–7, 87 FR 75711,

Dec. 9, 2022]

§ 60.19

Inspection, continuing quali-

fication evaluation, and mainte-

nance requirements.

(a)

Inspection. No sponsor may use or

allow the use of or offer the use of an

FSTD for flight crewmember training,

evaluation, or flight experience to

meet any of the requirements of this

chapter unless the sponsor does the fol-

lowing:

VerDate Sep<11>2014

14:00 Mar 14, 2024

Jkt 262047

PO 00000

Frm 00022

Fmt 8010

Sfmt 8010

Q:\14\14V2.TXT

PC31

aworley on LAPBH6H6L3 with DISTILLER

13

Federal Aviation Administration, DOT

§ 60.21

(1) Accomplishes all appropriate ob-

jective tests each year as specified in

the applicable QPS.

(2) Completes a functional preflight

check within the preceding 24 hours.

(b)

Continuing qualification evaluation.

(1) This evaluation consists of objec-

tive tests, and subjective tests, includ-

ing general FSTD requirements, as de-

scribed in the applicable QPS or as

may be amended by an FSTD Direc-

tive.

(2) The sponsor must contact the re-

sponsible Flight Standards office to

schedule the FSTD for continuing qual-

ification evaluations not later than 60

days before the evaluation is due.

(3) The sponsor must provide the re-

sponsible Flight Standards office re-

sponsible Flight Standards office ac-

cess to the objective test results in the

MQTG and access to the FSTD for the

length of time necessary for the re-

sponsible Flight Standards office to

complete the required continuing qual-

ification evaluations.

(4) The frequency of the responsible

Flight Standards office-conducted con-

tinuing qualification evaluations for

each FSTD will be established by the

responsible Flight Standards office and

specified in the Statement of Qualifica-

tion.

(5) Continuing qualification evalua-

tions conducted in the 3 calendar

months before or after the calendar

month in which these continuing quali-

fication evaluations are required will

be considered to have been conducted

in the calendar month in which they

were required.

(6) No sponsor may use or allow the

use of or offer the use of an FSTD for

flight crewmember training or evalua-

tion or for obtaining flight experience

for the flight crewmember to meet any

requirement of this chapter unless the

FSTD has passed a responsible Flight

Standards office-conducted continuing

qualification evaluation within the

time frame specified in the Statement

of Qualification or within the grace pe-

riod as described in paragraph (b)(5) of

this section.

(c)

Maintenance. The sponsor is re-

sponsible for continuing corrective and

preventive maintenance on the FSTD

to ensure that it continues to meet the

requirements of this part and the appli-

cable QPS appendix. No sponsor may

use or allow the use of or offer the use

of an FSTD for flight crewmember

training, evaluation, or flight experi-

ence to meet any of the requirements

of this chapter unless the sponsor does

the following:

(1) Maintains a discrepancy log.

(2) Ensures that, when a discrepancy

is discovered, the following require-

ments are met:

(i) A description of each discrepancy

is entered in the log and remains in the

log until the discrepancy is corrected

as specified in § 60.25(b).

(ii) A description of the corrective

action taken for each discrepancy, the

identity of the individual taking the

action, and the date that action is

taken is entered in the log.

(iii) The discrepancy log is kept in a

form and manner acceptable to the Ad-

ministrator and is kept in or adjacent

to the FSTD. An electronic log that

may be accessed by an appropriate ter-

minal or display in or adjacent to the

FSTD is satisfactory.

[Docket No. FAA–2002–12461, 71 FR 63426, Oct.

30, 2006, as amended by Docket FAA–2014–

0391, Amdt. 60–4, 81 FR 18218, Mar. 30, 2016;

Docket No. FAA–2022–1355, Amdt. No. 60–7, 87

FR 75711, Dec. 9, 2022]

§ 60.20

Logging FSTD discrepancies.

Each instructor, check airman, or

representative of the Administrator

conducting training, evaluation, or

flight experience, and each person con-

ducting the preflight inspection who

discovers a discrepancy, including any

missing, malfunctioning, or inoper-

ative components in the FSTD, must

write or cause to be written a descrip-

tion of that discrepancy into the dis-

crepancy log at the end of the FSTD

preflight or FSTD use session.

§ 60.21

Interim qualification of FSTDs

for new aircraft types or models.

(a) A sponsor may apply for and the

responsible Flight Standards office

may issue an interim qualification

level for an FSTD for a new type or

model of aircraft, even though the air-

craft manufacturer’s aircraft data

package is preliminary, if the sponsor

provides the following to the satisfac-

tion of the responsible Flight Stand-

ards office—

VerDate Sep<11>2014

14:00 Mar 14, 2024

Jkt 262047

PO 00000

Frm 00023

Fmt 8010

Sfmt 8010

Q:\14\14V2.TXT

PC31

aworley on LAPBH6H6L3 with DISTILLER

14

14 CFR Ch. I (1–1–24 Edition)

§ 60.23

(1) The aircraft manufacturer’s data,

which consists of at least predicted

data, validated by a limited set of

flight test data;

(2) The aircraft manufacturer’s de-

scription of the prediction method-

ology used to develop the predicted

data; and

(3) The QTG test results.

(b) An FSTD that has been issued in-

terim qualification is deemed to have

been issued initial qualification unless

the responsible Flight Standards office

rescinds the qualification. Interim

qualification terminates two years

after its issuance, unless the respon-

sible Flight Standards office deter-

mines that specific conditions warrant

otherwise.

(c) Within twelve months of the re-

lease of the final aircraft data package

by the aircraft manufacturer, but no

later than two years after the issuance

of the interim qualification status, the

sponsor must apply for initial quali-

fication in accordance with § 60.15 based

on the final aircraft data package ap-

proved by the aircraft manufacturer,

unless the responsible Flight Standards

office determines that specific condi-

tions warrant otherwise.

(d) An FSTD with interim qualifica-

tion may be modified only in accord-

ance with § 60.23.

[Docket No. FAA–2002–12461, 71 FR 63426, Oct.

30, 2006, as amended by Docket No. FAA–

2022–1355, Amdt. No. 60–7, 87 FR 75711, Dec. 9,

2022]

§ 60.23

Modifications to FSTDs.

(a)

Description of a modification. For

the purposes of this part, an FSTD is

said to have been modified when:

(1) Equipment or devices intended to

simulate aircraft appliances are added

to or removed from FSTD, which

change the Statement of Qualification

or the MQTG; or

(2) Changes are made to either soft-

ware or hardware that are intended to

impact flight or ground dynamics;

changes are made that impact perform-

ance or handling characteristics of the

FSTD (including motion, visual, con-

trol loading, or sound systems for

those FSTD levels requiring sound

tests and measurements); or changes

are made to the MQTG. Changes to the

MQTG which do not affect required ob-

jective testing results or validation

data approved during the initial eval-

uation of the FSTD are not considered

modifications under this section.

(b)

FSTD Directive. When the FAA de-

termines that FSTD modification is

necessary for safety of flight reasons,

the sponsor of each affected FSTD

must ensure that the FSTD is modified

according to the FSTD Directive re-

gardless of the original qualification

standards applicable to any specific

FSTD.

(c)

Using the modified FSTD. The spon-

sor may not use, or allow the use of, or

offer the use of, the FSTD with the

proposed modification for flight crew-

member training or evaluation or for

obtaining flight experience for the

flight crewmember to meet any re-

quirement of this chapter unless:

(1) The sponsor has notified the re-

sponsible Flight Standards office and

the TPAA of their intent to incor-

porate the proposed modification, and

one of the following has occurred;

(i) Twenty-one days have passed

since the sponsor notified the respon-

sible Flight Standards office and the

TPAA of the proposed modification and

the sponsor has not received any re-

sponse from either the responsible

Flight Standards office or the TPAA;

(ii) Twenty-one days have passed

since the sponsor notified the respon-

sible Flight Standards office and the

TPAA of the proposed modification and

one has approved the proposed modi-

fication and the other has not re-

sponded;

(iii) Fewer than twenty-one days

have passed since the sponsor notified

the responsible Flight Standards office

and the TPAA of the proposed modi-

fication and the responsible Flight

Standards office and TPAA both ap-

prove the proposed modification;

(iv) The sponsor has successfully

completed any evaluation the respon-

sible Flight Standards office may re-

quire in accordance with the standards

for an evaluation for initial qualifica-

tion or any part thereof before the

modified FSTD is placed in service.

(2) The notification is submitted with

the content as, and in a form and man-

ner as, specified in the applicable QPS.

(d)

User notification. When a modifica-

tion is made to an FSTD that affects

VerDate Sep<11>2014

14:00 Mar 14, 2024

Jkt 262047

PO 00000

Frm 00024

Fmt 8010

Sfmt 8010

Q:\14\14V2.TXT

PC31

aworley on LAPBH6H6L3 with DISTILLER

15

Federal Aviation Administration, DOT

§ 60.27

the Statement of Qualification, the

sponsor must post an addendum to the

Statement of Qualification until such

time as a permanent, updated state-

ment is posted.

(e)

MQTG update. The MQTG must be

updated with current objective test re-

sults in accordance with § 60.15(h) and

(i) and appropriate objective data in

accordance with § 60.13, each time an

FSTD is modified and an objective test

or other MQTG section is affected by

the modification. If an FSTD Directive

is the cause of this update, the direc-

tion to make the modification and the

record of the modification completion

must be filed in the MQTG.

[Docket No. FAA–2002–12461, 71 FR 63426, Oct.

30, 2006, as amended by Docket FAA–2014–

0391, Amdt. 60–4, 81 FR 18218, Mar. 30, 2016;

Docket No. FAA–2022–1355, Amdt. No. 60–7, 87

FR 75711, Dec. 9, 2022]

§ 60.25

Operation with missing, mal-

functioning, or inoperative compo-

nents.

(a) No person may knowingly use or

allow the use of or misrepresent the ca-

pability of an FSTD for any maneuver,

procedure, or task that is to be accom-

plished to meet training, evaluation, or

flight experience requirements of this

chapter for flight crewmember certifi-

cation or qualification when there is a

missing, malfunctioning, or inoper-

ative (MMI) component that is re-

quired to be present and correctly oper-

ate for the satisfactory completion of

that maneuver, procedure, or task.

(b) Each MMI component as de-

scribed in paragraph (a) of this section,

or any MMI component installed and

required to operate correctly to meet

the current Statement of Qualification,

must be repaired or replaced within 30

calendar days, unless otherwise re-

quired or authorized by the responsible

Flight Standards office.

(c) A list of the current MMI compo-

nents must be readily available in or

adjacent to the FSTD for review by

users of the device. Electronic access

to this list via an appropriate terminal

or display in or adjacent to the FSTD

is satisfactory. The discrepancy log

may be used to satisfy this require-

ment provided each currently MMI

component is listed in the discrepancy

log.

[Docket No. FAA–2002–12461, 71 FR 63426, Oct.

30, 2006, as amended by Docket No. FAA–

2022–1355, Amdt. No. 60–7, 87 FR 75711, Dec. 9,

2022]

§ 60.27

Automatic loss of qualification

and procedures for restoration of

qualification.

(a) An FSTD qualification is auto-

matically lost when any of the fol-

lowing occurs:

(1) The FSTD is not used in the spon-

sor’s FAA-approved flight training pro-

gram in accordance with § 60.7(b)(5) or

(b)(6) and the sponsor does not obtain

and maintain the written statement as

described in § 60.7(d)(2).

(2) The FSTD is not inspected in ac-

cordance with § 60.19.

(3) The FSTD is physically moved

from one location and installed in a

different location, regardless of dis-

tance.

(4) The MQTG is missing or otherwise

not available and a replacement is not

made within 30 days.

(b) If FSTD qualification is lost

under paragraph (a) of this section,

qualification is restored when either of

the following provisions is met:

(1) The FSTD successfully passes an

evaluation:

(i) For initial qualification, in ac-

cordance with §§ 60.15 and 60.17(c) in

those circumstances where the respon-

sible Flight Standards office has deter-

mined that a full evaluation for initial

qualification is necessary; or

(ii) For those elements of an evalua-

tion for initial qualification, in accord-

ance with §§ 60.15 and 60.17(c), as deter-

mined to be necessary by the respon-

sible Flight Standards office.

(2) The responsible Flight Standards

office advises the sponsor that an eval-

uation is not necessary.

(c) In making the determinations de-

scribed in paragraph (b) of this section,

the responsible Flight Standards office

considers factors including the number

of continuing qualification evaluations

missed, the number of sponsor-con-

ducted quarterly inspections missed,

VerDate Sep<11>2014

14:00 Mar 14, 2024

Jkt 262047

PO 00000

Frm 00025

Fmt 8010

Sfmt 8010

Q:\14\14V2.TXT

PC31

aworley on LAPBH6H6L3 with DISTILLER

16

14 CFR Ch. I (1–1–24 Edition)

§ 60.29

and the care that had been taken of the

device since the last evaluation.

[Docket No. FAA–2002–12461, 71 FR 63426, Oct.

30, 2006, as amended by Docket No. FAA–

2022–1355, Amdt. No. 60–7, 87 FR 75711, Dec. 9,

2022]

§ 60.29

Other losses of qualification

and procedures for restoration of

qualification.

(a) Except as provided in paragraph

(c) of this section, when the responsible

Flight Standards office determines

that the FSTD no longer meets quali-

fication standards, the following proce-

dure applies:

(1) The responsible Flight Standards

office notifies the sponsor in writing

that the FSTD no longer meets some

or all of its qualification standards.

(2) The responsible Flight Standards

office sets a reasonable period (but not

less than 7 days) within which the

sponsor may submit written informa-

tion, views, and arguments on the

FSTD qualification.

(3) After considering all material pre-

sented, the responsible Flight Stand-

ards office notifies the sponsor about

the determination with regard to the

qualification of the FSTD.

(4) When the responsible Flight

Standards office notifies the sponsor

that some or all of the FSTD is no

longer qualified, the action described

in the notification becomes effective

not less than 30 days after the sponsor

receives that notice unless—

(i) The responsible Flight Standards

office finds under paragraph (c) of this

section that there is an emergency re-

quiring immediate action with respect

to safety in air commerce; or

(ii) The sponsor petitions the Execu-

tive Director of Flight Standards Serv-

ice for reconsideration of the respon-

sible Flight Standards office finding

under paragraph (b) of this section.

(b) When a sponsor seeks reconsider-

ation of a decision from the responsible

Flight Standards office concerning the

FSTD qualification, the following pro-

cedure applies:

(1) The sponsor must petition for re-

consideration of that decision within 30

days of the date that the sponsor re-

ceives a notice that some or all of the

FSTD is no longer qualified.

(2) The sponsor must address its peti-

tion to the Executive Director, Flight

Standards Service, Federal Aviation

Administration, 800 Independence Ave.,

SW., Washington, DC 20591.

(3) A petition for reconsideration, if

filed within the 30-day period, suspends

the effectiveness of the determination

by the responsible Flight Standards of-

fice that the FSTD is no longer quali-

fied unless the responsible Flight

Standards office has found, under para-

graph (c) of this section, that an emer-

gency exists requiring immediate ac-

tion with respect to safety in air com-

merce.

(c) If the responsible Flight Stand-

ards office find that an emergency ex-

ists requiring immediate action with

respect to safety in air commerce that

makes the procedures set out in this

section impracticable or contrary to

the public interest:

(1) The responsible Flight Standards

office withdraws qualification of some

or all of the FSTD and makes the with-

drawal of qualification effective on the

day the sponsor receives notice of it.

(2) In the notice to the sponsor, the

responsible Flight Standards office ar-

ticulates the reasons for its finding

that an emergency exists requiring im-

mediate action with respect to safety

in air transportation or air commerce

or that makes it impracticable or con-

trary to the public interest to stay the

effectiveness of the finding.

(d) FSTD qualification lost under

paragraph (a) or (c) of this section may

be restored when either of the fol-

lowing provisions are met:

(1) The FSTD successfully passes an

evaluation for initial qualification, in

accordance with §§ 60.15 and 60.17(c) in

those circumstances where the respon-

sible Flight Standards office has deter-

mined that a full evaluation for initial

qualification is necessary; or

(2) The FSTD successfully passes an

evaluation for those elements of an ini-

tial qualification evaluation, in accord-

ance with §§ 60.15 and 60.17(c), as deter-

mined to be necessary by the respon-

sible Flight Standards office.

(e) In making the determinations de-

scribed in paragraph (d) of this section,

the responsible Flight Standards office

considers factors including the reason

VerDate Sep<11>2014

14:00 Mar 14, 2024

Jkt 262047

PO 00000

Frm 00026

Fmt 8010

Sfmt 8010

Q:\14\14V2.TXT

PC31

aworley on LAPBH6H6L3 with DISTILLER

17

Federal Aviation Administration, DOT

§ 60.33

for the loss of qualification, any re-

pairs or replacements that may have to

have been completed, the number of

continuing qualification evaluations

missed, the number of sponsor-con-

ducted quarterly inspections missed,

and the care that had been taken of the

device since the loss of qualification.

[Docket No. FAA–2002–12461, 71 FR 63426, Oct.

30, 2006, as amended by Docket FAA–2018–

0119, Amdt. 60–5, 83 FR 9170, Mar. 5, 2018;

Docket No. FAA–2022–1355, Amdt. No. 60–7, 87

FR 75711, Dec. 9, 2022]

§ 60.31

Recordkeeping and reporting.

(a) The FSTD sponsor must maintain

the following records for each FSTD it

sponsors:

(1) The MQTG and each amendment

thereto.

(2) A record of all FSTD modifica-

tions affected under § 60.23 since the

issuance of the original Statement of

Qualification.

(3) A copy of all of the following:

(i) Results of the qualification eval-

uations (initial and each upgrade) since

the issuance of the original Statement

of Qualification.

(ii) Results of the objective tests con-

ducted in accordance with § 60.19(a) for

a period of 2 years.

(iii) Results of the previous three

continuing qualification evaluations,

or the continuing qualification evalua-

tions from the previous 2 years, which-

ever covers a longer period.

(iv) Comments obtained in accord-

ance with § 60.9(b) for a period of at

least 90 days.

(4) A record of all discrepancies en-

tered in the discrepancy log over the

previous 2 years, including the fol-

lowing:

(i) A list of the components or equip-

ment that were or are missing, mal-

functioning, or inoperative.

(ii) The action taken to correct the

discrepancy.

(iii) The date the corrective action

was taken.

(iv) The identity of the person deter-

mining that the discrepancy has been

corrected.

(b) The records specified in this sec-

tion must be maintained in plain lan-

guage form or in coded form if the

coded form provides for the preserva-

tion and retrieval of information in a

manner acceptable to the responsible

Flight Standards office.

[Docket No. FAA–2002–12461, 71 FR 63426, Oct.

30, 2006, as amended by Docket No. FAA–

2022–1355, Amdt. No. 60–7, 87 FR 75711, Dec. 9,

2022]

§ 60.33

Applications, logbooks, reports,

and records: Fraud, falsification, or

incorrect statements.

(a) No person may make, or cause to

be made, any of the following:

(1) A fraudulent or intentionally false

statement in any application or any

amendment thereto, or any other re-

port or test result required by this

part.

(2) A fraudulent or intentionally false

statement in or a known omission from

any record or report that is kept,

made, or used to show compliance with

this part, or to exercise any privileges

under this chapter.

(3) Any reproduction or alteration,

for fraudulent purpose, of any report,

record, or test result required under

this part.

(b) The commission by any person of

any act prohibited under paragraph (a)

of this section is a basis for any one or

any combination of the following:

(1) A civil penalty.

(2) Suspension or revocation of any

certificate held by that person that

was issued under this chapter.

(3) The removal of FSTD qualifica-

tion and approval for use in a training

program.

(c) The following may serve as a basis

for removal of qualification of an

FSTD including the withdrawal of ap-

proval for use of an FSTD; or denying

an application for a qualification:

(1) An incorrect statement, upon

which the FAA relied or could have re-

lied, made in support of an application

for a qualification or a request for ap-

proval for use.

(2) An incorrect entry, upon which

the FAA relied or could have relied,

made in any logbook, record, or report

that is kept, made, or used to show

compliance with any requirement for

an FSTD qualification or an approval

for use.

VerDate Sep<11>2014

14:00 Mar 14, 2024

Jkt 262047

PO 00000

Frm 00027

Fmt 8010

Sfmt 8010

Q:\14\14V2.TXT

PC31

aworley on LAPBH6H6L3 with DISTILLER

18

14 CFR Ch. I (1–1–24 Edition)

§ 60.35

§ 60.35

Specific full flight simulator

compliance requirements.

(a) No device will be eligible for ini-

tial or upgrade qualification to a FFS

at Level C or Level D under this part

unless it includes the equipment and

appliances installed and operating to

the extent necessary for the issuance of

an airman certificate or rating.

(b) No device will be eligible for ini-

tial or upgrade qualification to a FFS

at Level A or Level B under this part

unless it includes the equipment and

appliances installed and operating to

the extent necessary for the training,

testing, and/or checking that comprise

the simulation portion of the require-

ments for issuance of an airman cer-

tificate or rating.

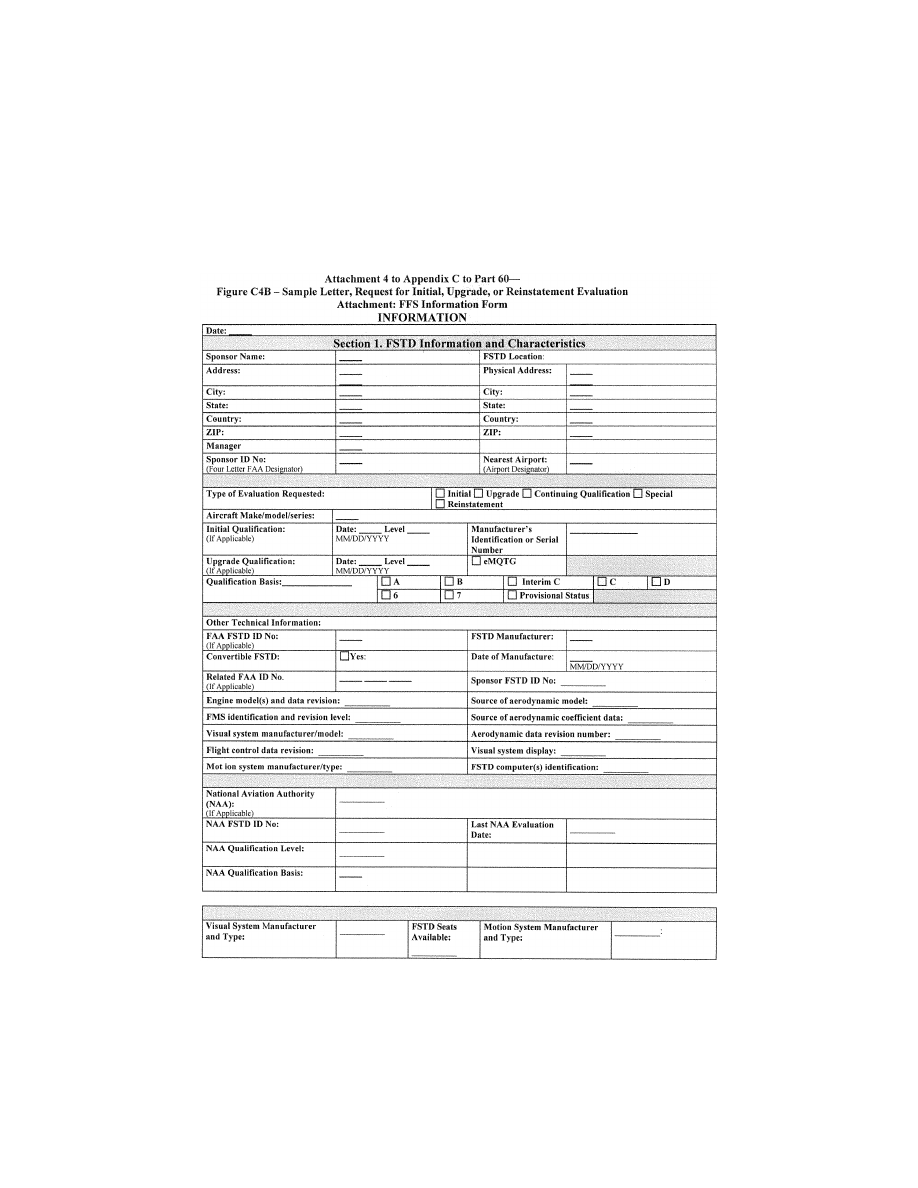

§ 60.37

FSTD qualification on the basis

of a Bilateral Aviation Safety Agree-

ment (BASA).

(a) The evaluation and qualification

of an FSTD by a contracting State to

the Convention on International Civil

Aviation for the sponsor of an FSTD

located in that contracting State may

be used as the basis for issuing a U.S.

statement of qualification (see applica-

ble QPS, attachment 4, figure 4) by the

responsible Flight Standards office to

the sponsor of that FSTD in accord-

ance with—

(1) A BASA between the United

States and the Contracting State that

issued the original qualification; and

(2) A Simulator Implementation Pro-

cedure (SIP) established under the

BASA.

(b) The SIP must contain any condi-

tions and limitations on validation and

issuance of such qualification by the

U.S.

[Docket No. FAA–2002–12461, 71 FR 63426, Oct.

30, 2006, as amended by Docket No. FAA–

2022–1355, Amdt. No. 60–7, 87 FR 75711, Dec. 9,

2022]

A

PPENDIX

A

TO

P

ART

60—Q

UALIFICATION

P

ERFORMANCE

S

TANDARDS FOR

A

IR

-

PLANE

F

ULL

F

LIGHT

S

IMULATORS

llllllllllllllllllllllll

B

EGIN

I

NFORMATION

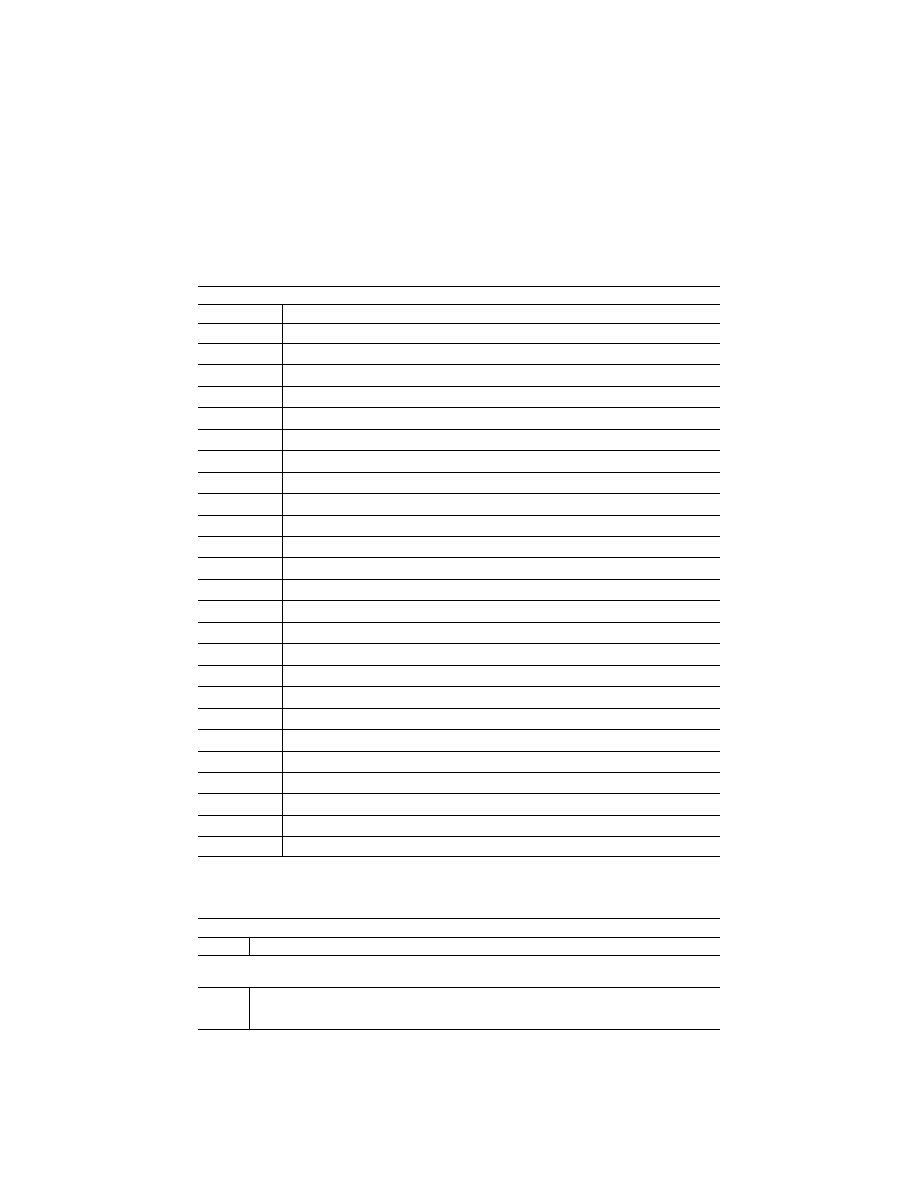

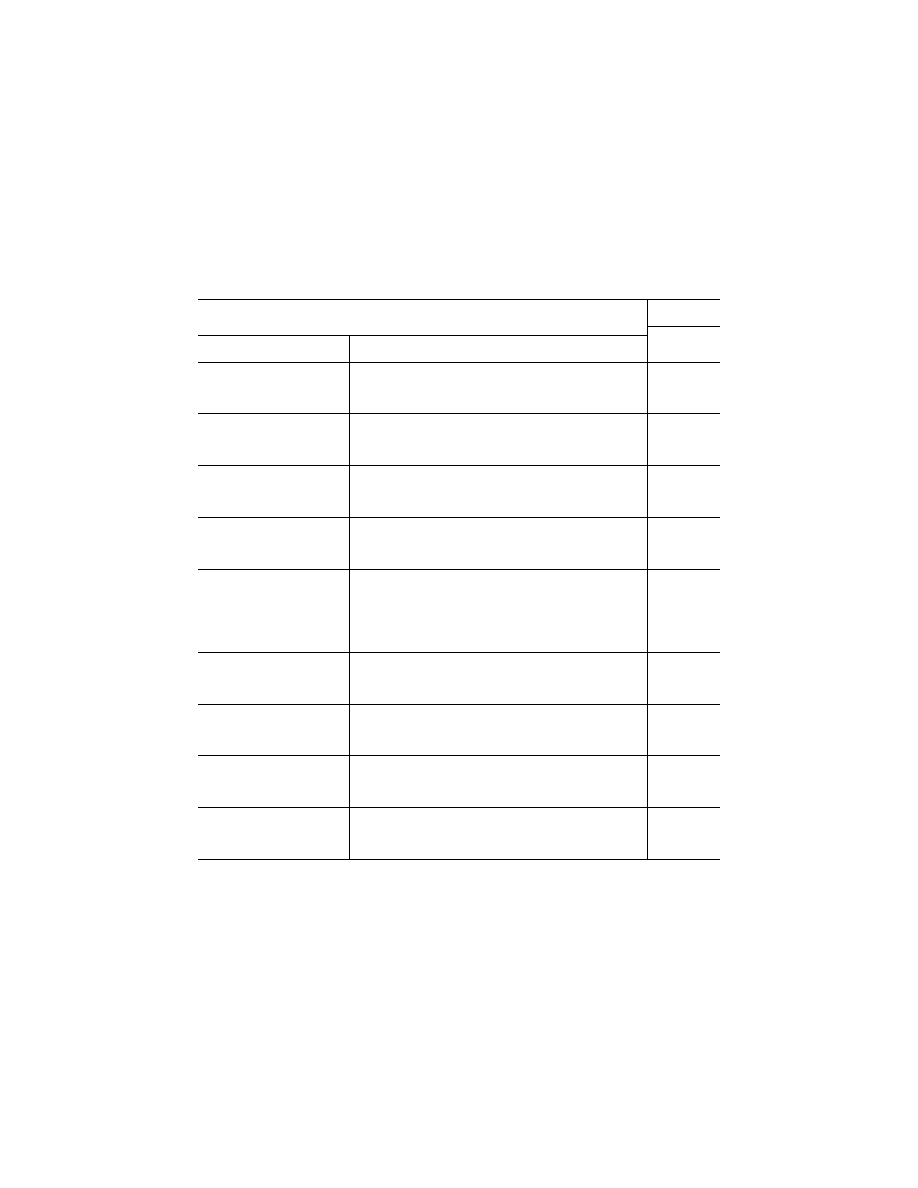

This appendix establishes the standards for

Airplane FFS evaluation and qualification.

The Flight Standards Service is responsible

for the development, application, and imple-

mentation of the standards contained within

this appendix. The procedures and criteria

specified in this appendix will be used by the

responsible Flight Standards office, when

conducting airplane FFS evaluations.

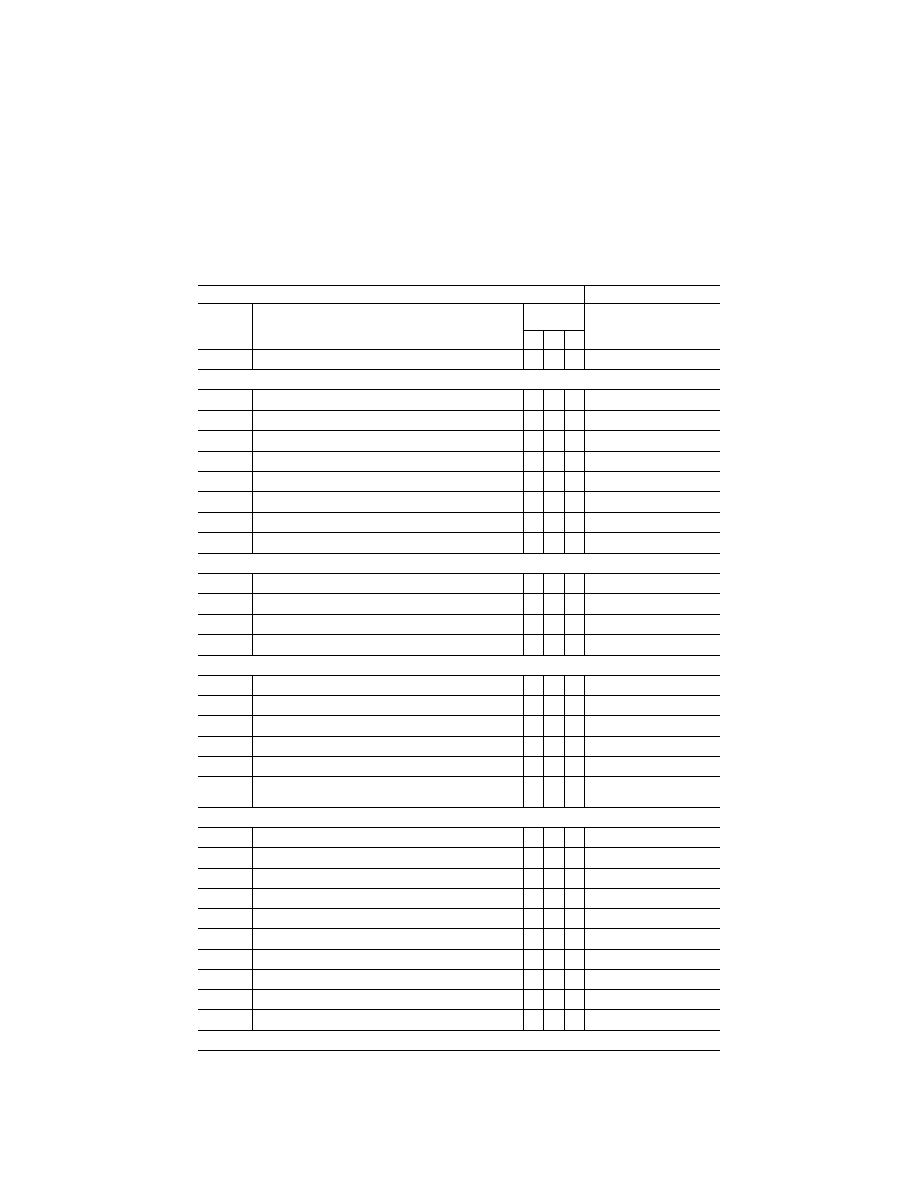

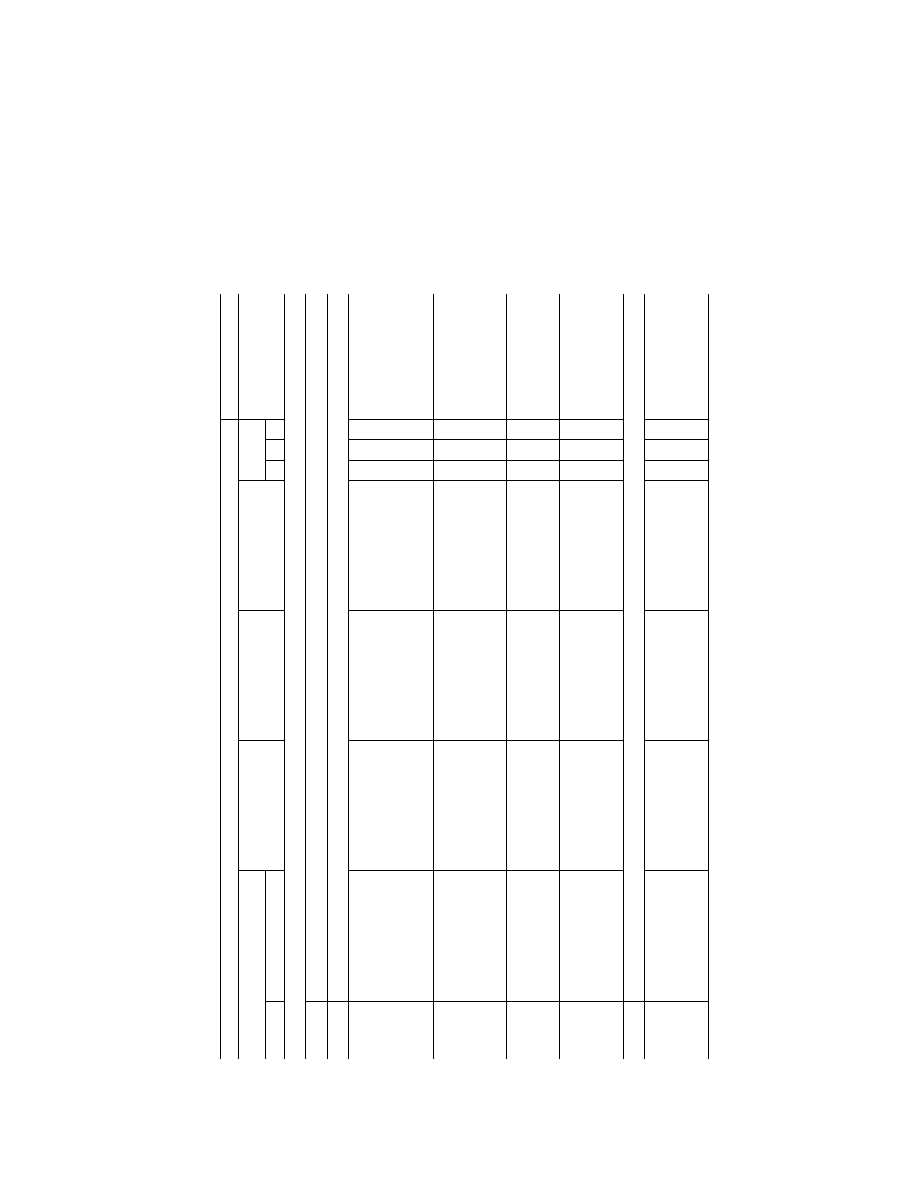

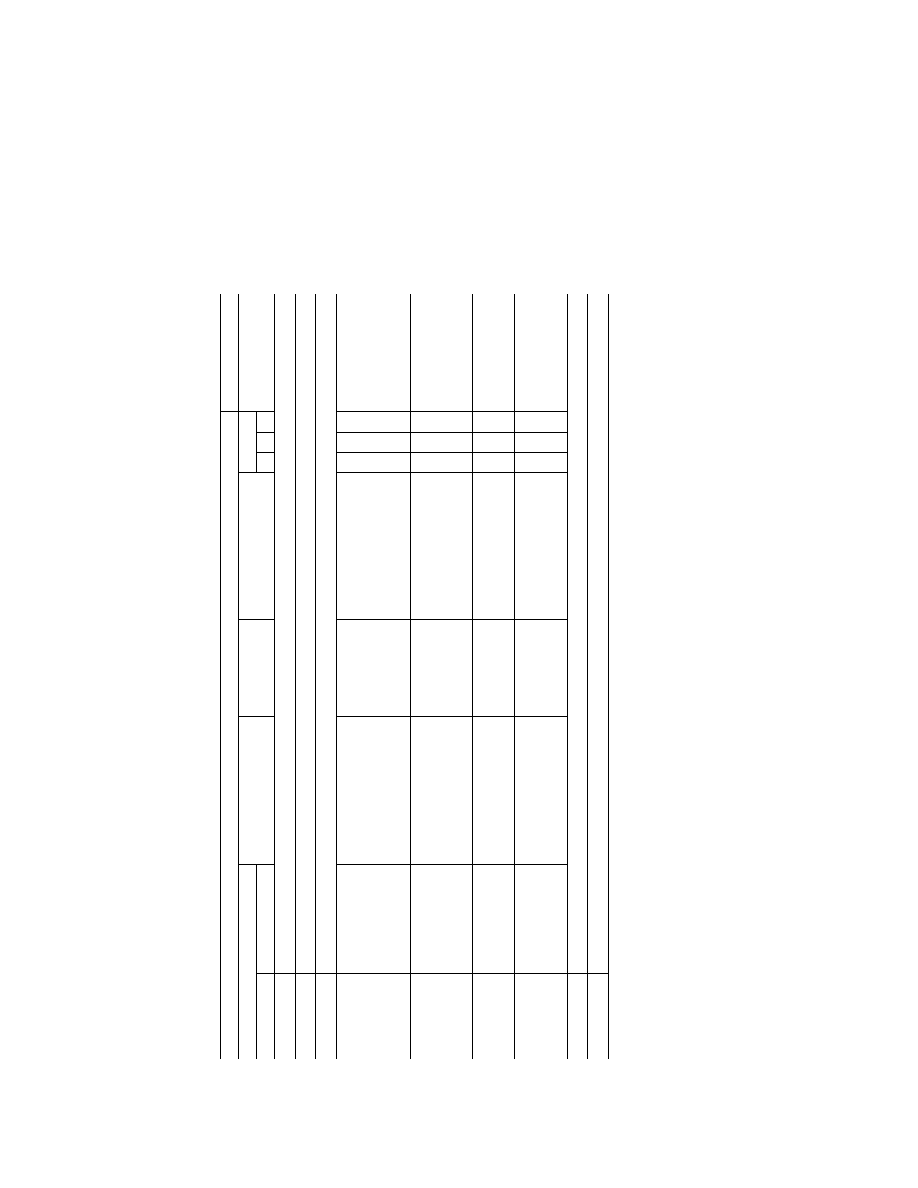

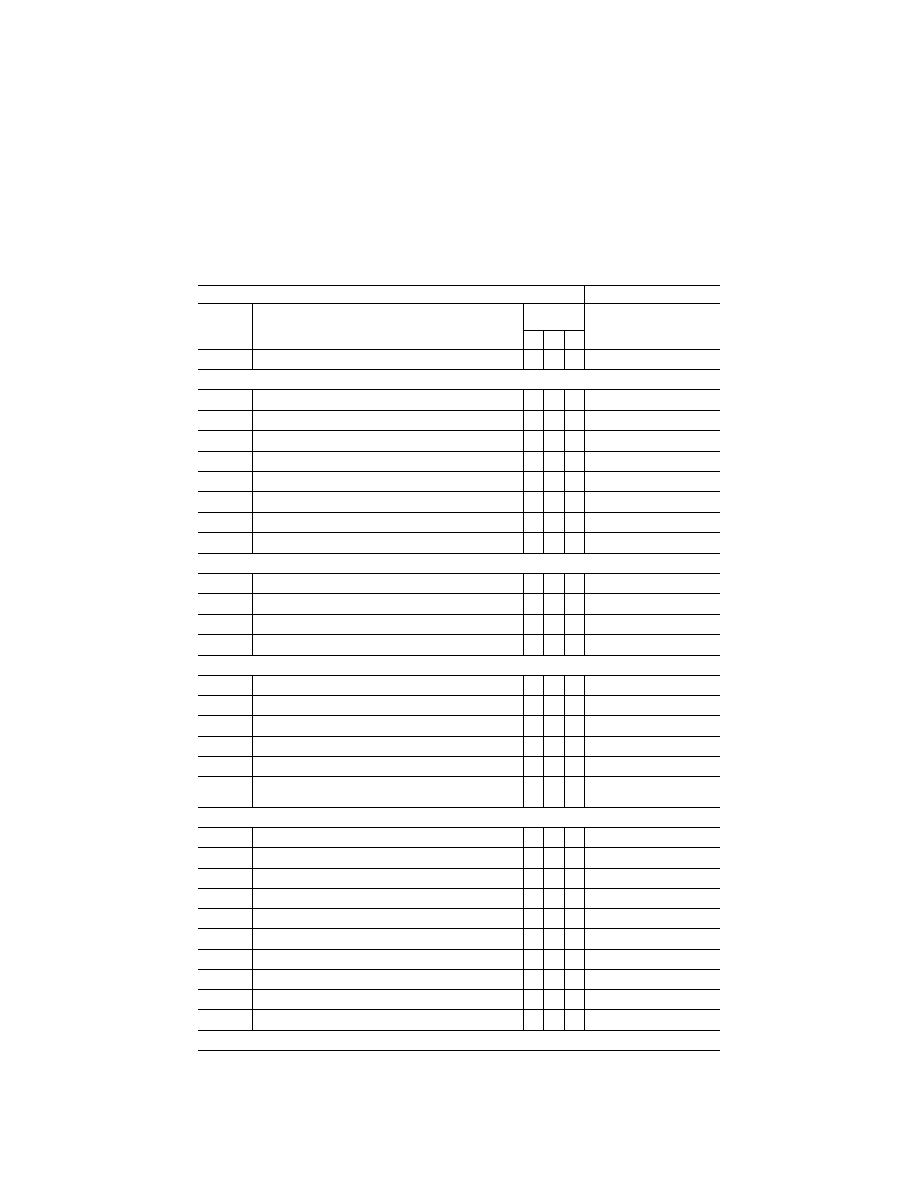

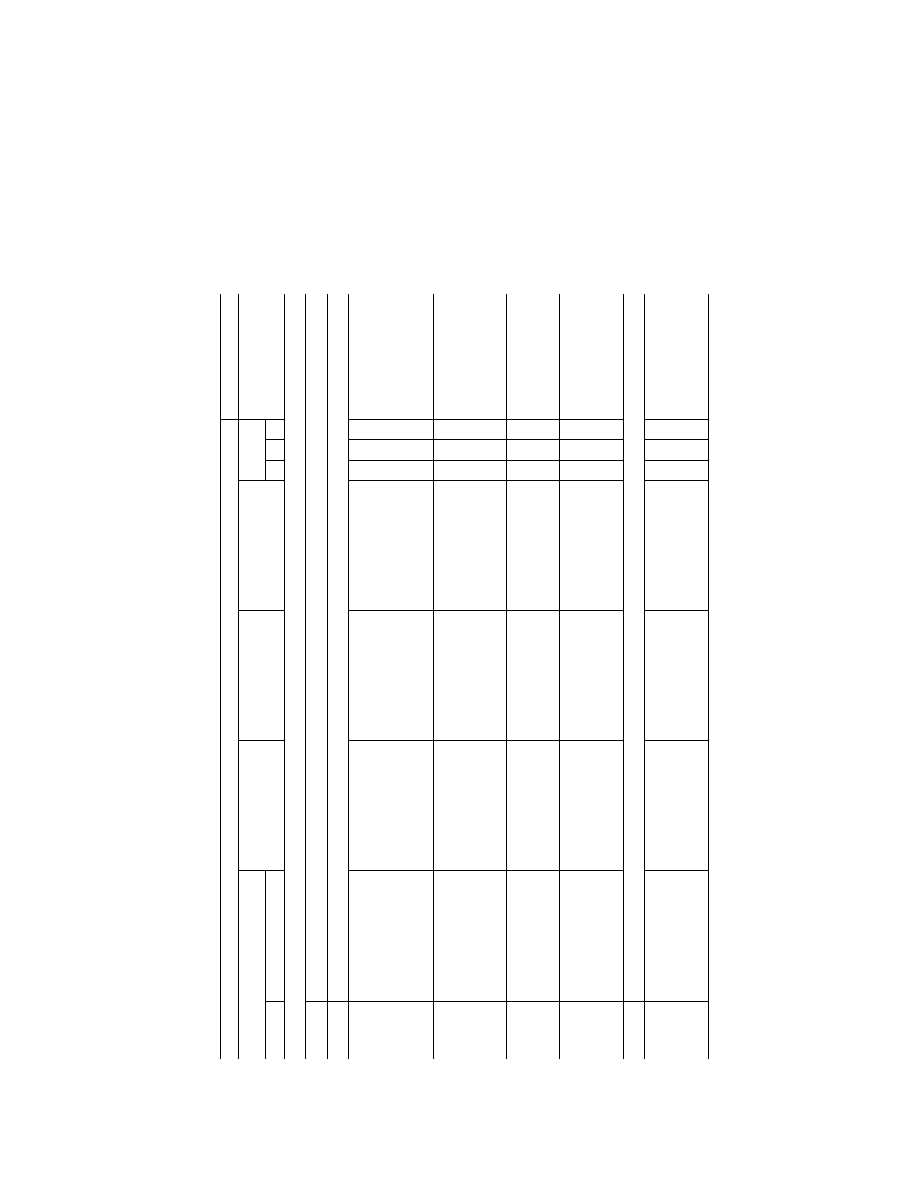

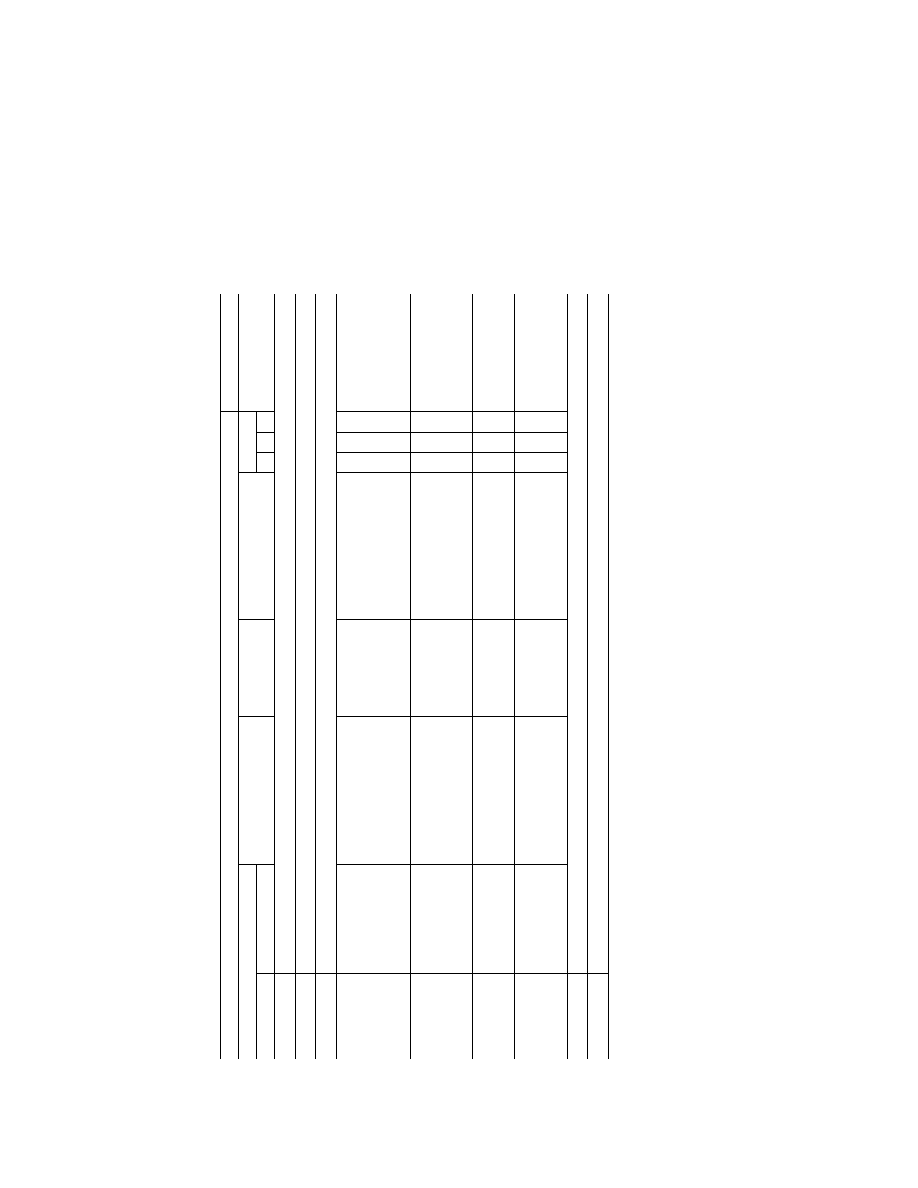

T

ABLE OF

C

ONTENTS

1. Introduction.

2. Applicability (§§ 60.1 and 60.2).

3. Definitions (§ 60.3).

4. Qualification Performance Standards

(§ 60.4).

5. Quality Management System (§ 60.5).

6. Sponsor Qualification Requirements

(§ 60.7).

7. Additional Responsibilities of the Sponsor

(§ 60.9).

8. FFS Use (§ 60.11).

9. FFS Objective Data Requirements (§ 60.13).

10. Special Equipment and Personnel Re-

quirements for Qualification of the FFS

(§ 60.14).

11. Initial (and Upgrade) Qualification Re-

quirements (§ 60.15).

12. Additional Qualifications for a Currently

Qualified FFS (§ 60.16).

13. Previously Qualified FFSs (§ 60.17).

14. Inspection, Continuing Qualification

Evaluation, and Maintenance Require-

ments (§ 60.19).

15. Logging FFS Discrepancies (§ 60.20).

16. Interim Qualification of FFSs for New

Airplane Types or Models (§ 60.21).

17. Modifications to FFSs (§ 60.23).

18. Operations With Missing, Malfunctioning,

or Inoperative Components (§ 60.25).

19. Automatic Loss of Qualification and Pro-

cedures for Restoration of Qualification

(§ 60.27).

20. Other Losses of Qualification and Proce-

dures for Restoration of Qualification

(§ 60.29).

21. Record Keeping and Reporting (§ 60.31).

22. Applications, Logbooks, Reports, and

Records: Fraud, Falsification, or Incor-

rect Statements (§ 60.33).

23. Specific FFS Compliance Requirements

(§ 60.35).

24. [Reserved]

25. FFS Qualification on the Basis of a Bilat-

eral Aviation Safety Agreement (BASA)

(§ 60.37).

Attachment 1 to Appendix A to Part 60—

General Simulator Requirements.

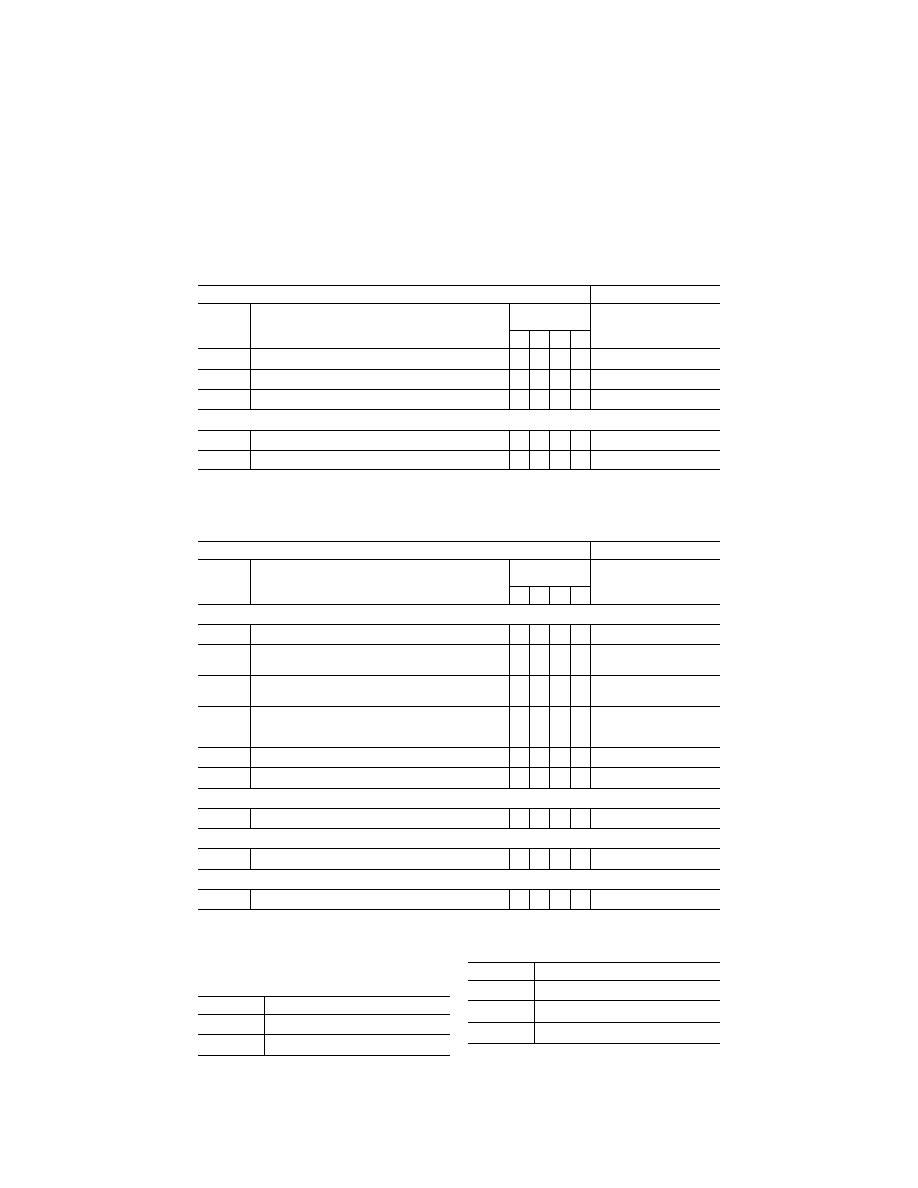

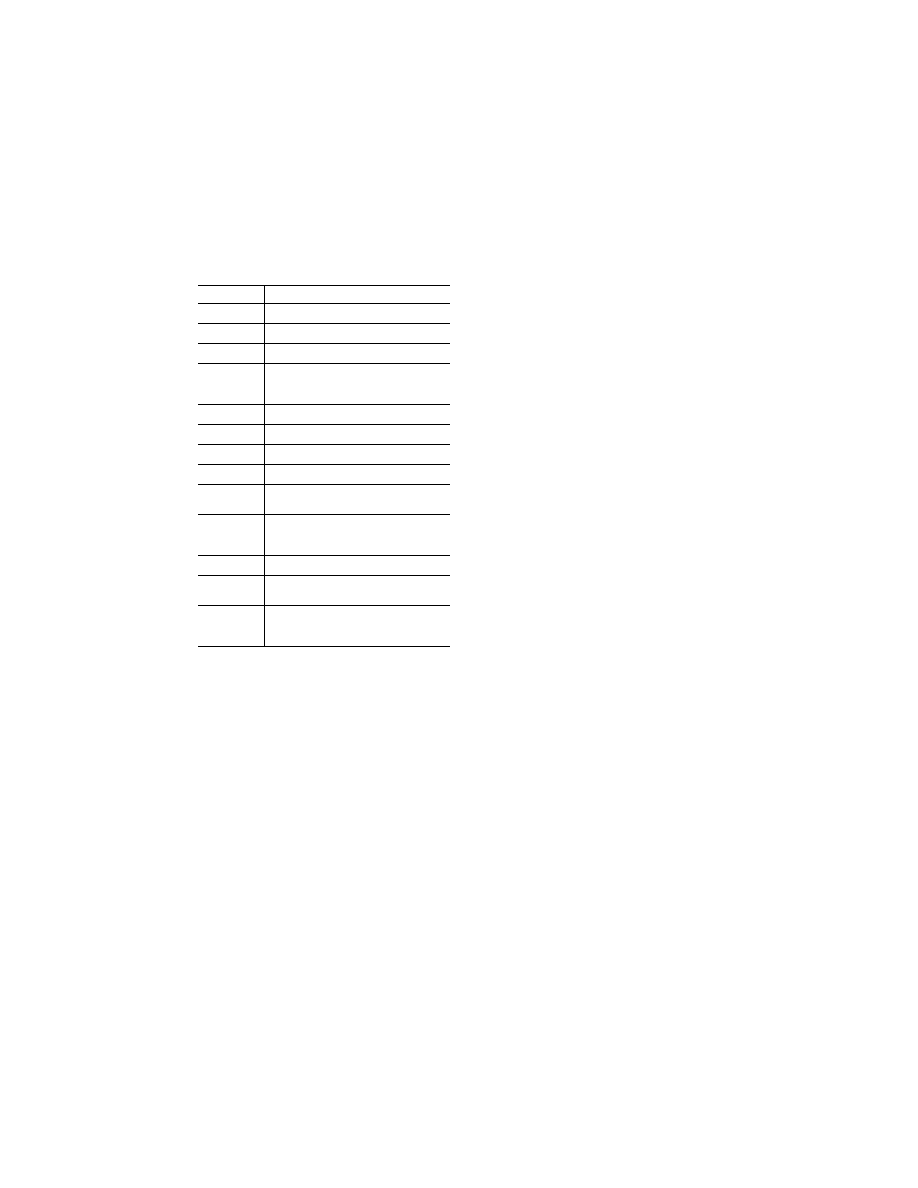

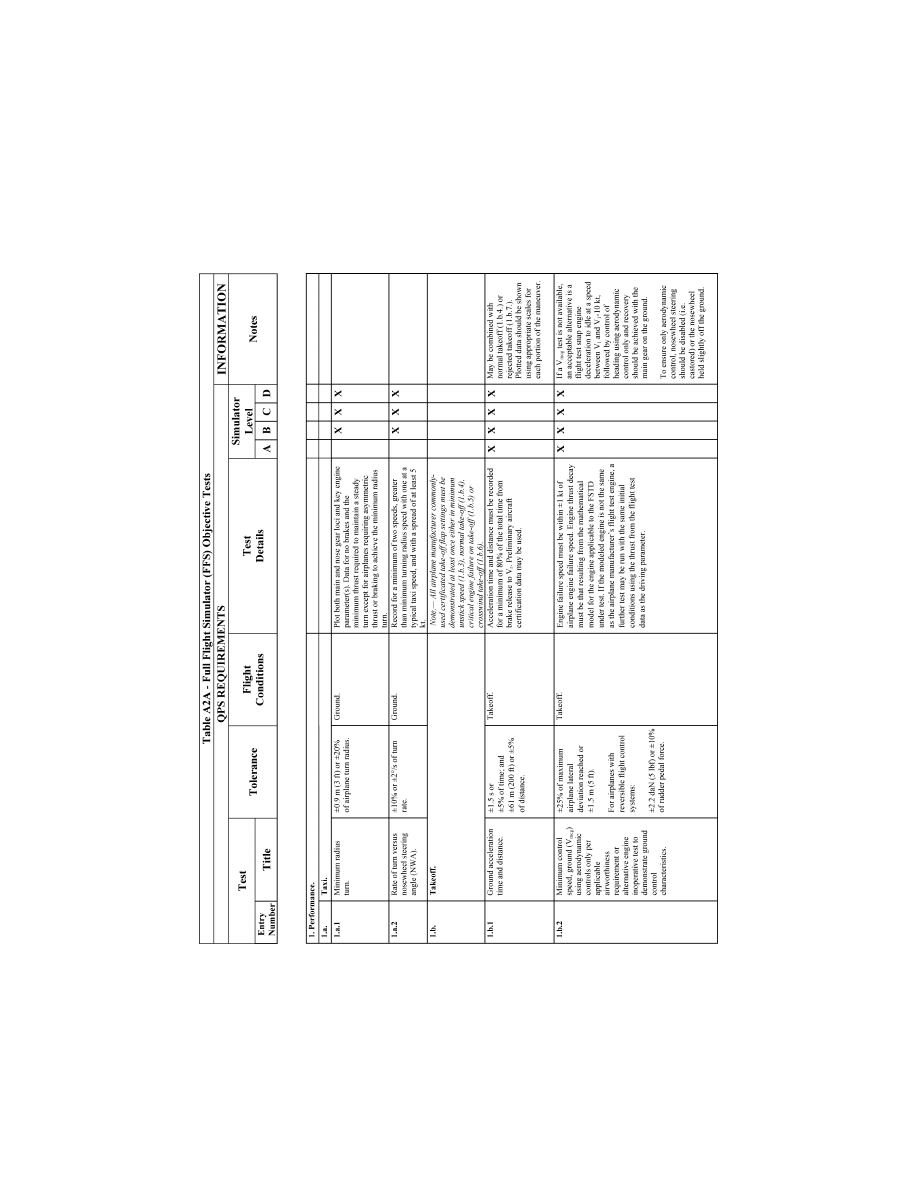

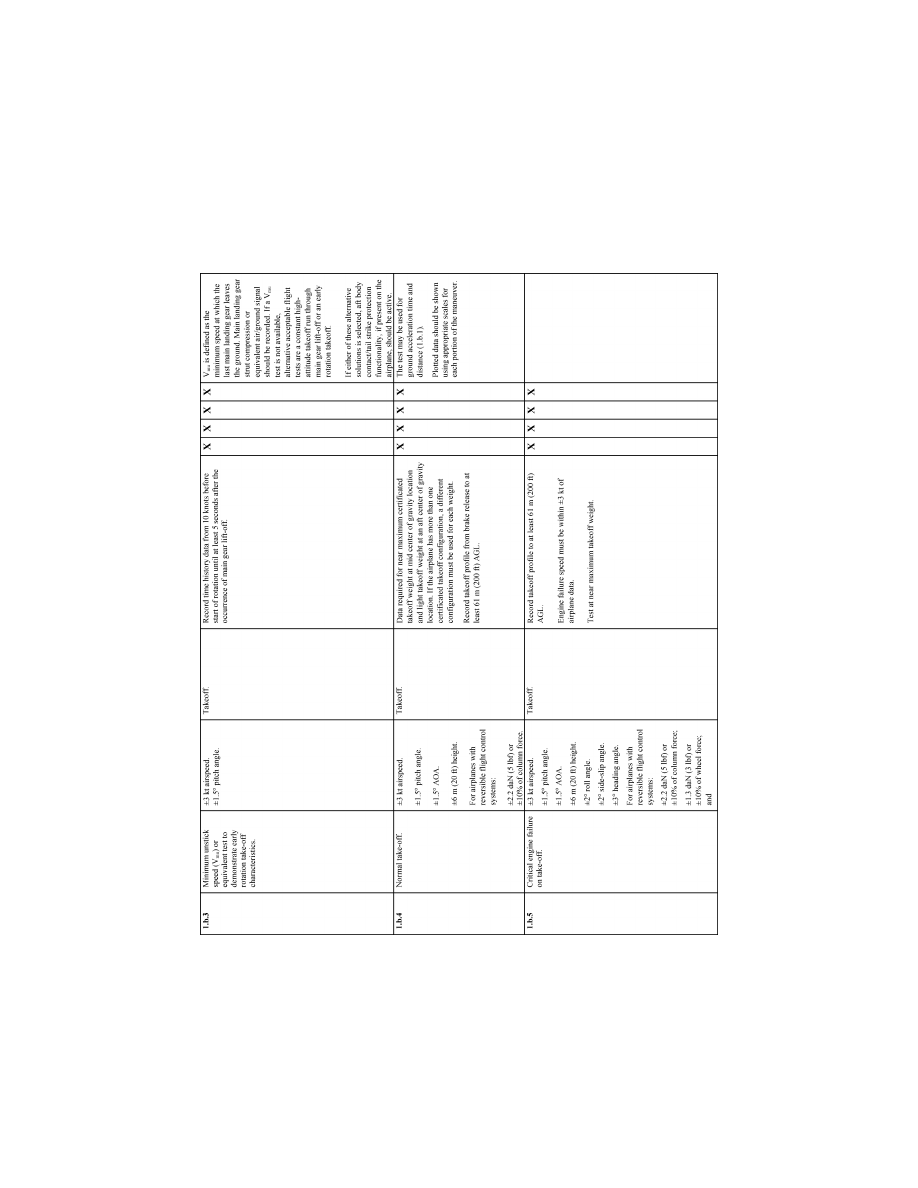

Attachment 2 to Appendix A to Part 60—FFS

Objective Tests.

Attachment 3 to Appendix A to Part 60—

Simulator Subjective Evaluation.

Attachment 4 to Appendix A to Part 60—

Sample Documents.

Attachment 5 to Appendix A to Part 60—

Simulator Qualification Requirements

for Windshear Training Program Use.

Attachment 6 to Appendix A to Part 60—

FSTD Directives Applicable to Airplane

Flight Simulators.

VerDate Sep<11>2014

14:00 Mar 14, 2024

Jkt 262047

PO 00000

Frm 00028

Fmt 8010

Sfmt 8002

Q:\14\14V2.TXT

PC31

aworley on LAPBH6H6L3 with DISTILLER

19

Federal Aviation Administration, DOT

Pt. 60, App. A

E

ND

I

NFORMATION

llllllllllllllllllllllll

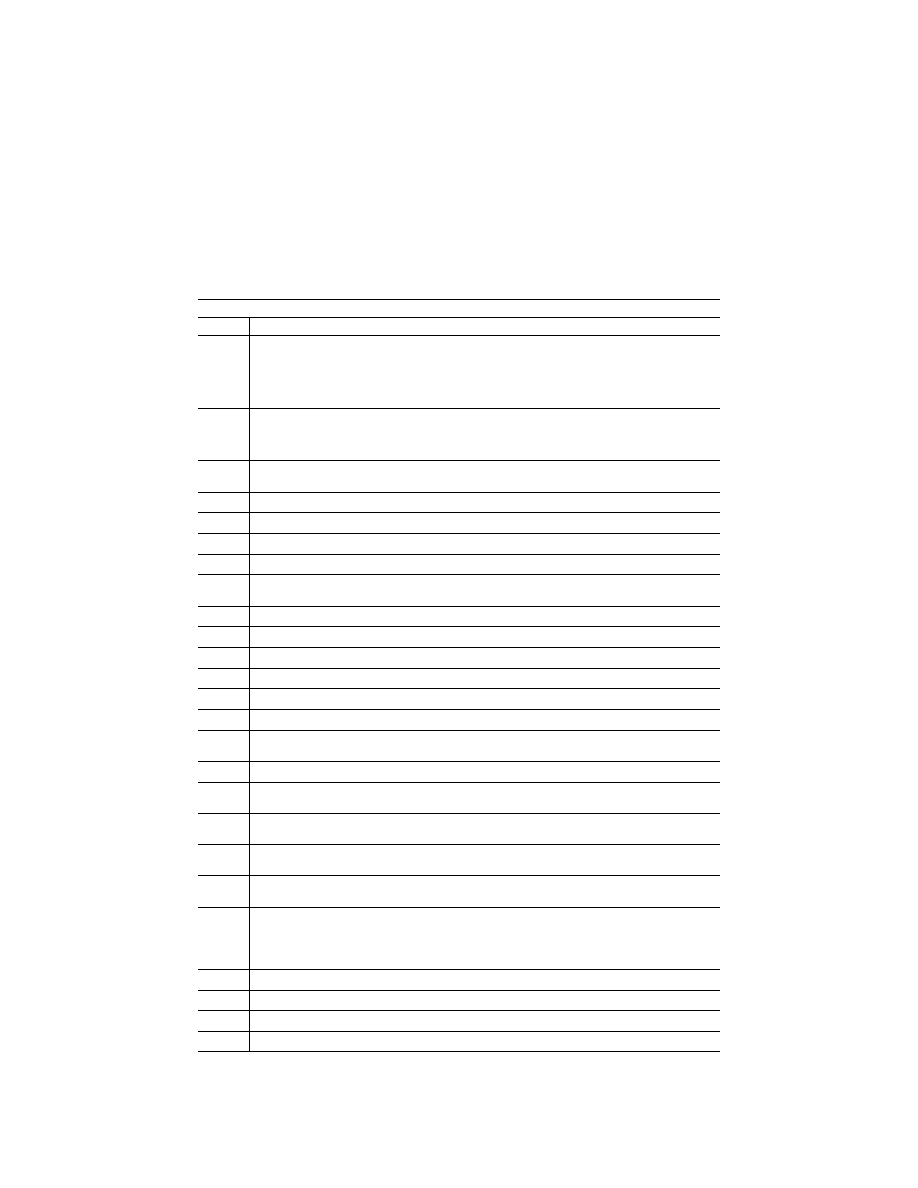

1. I

NTRODUCTION

llllllllllllllllllllllll

B

EGIN

I

NFORMATION

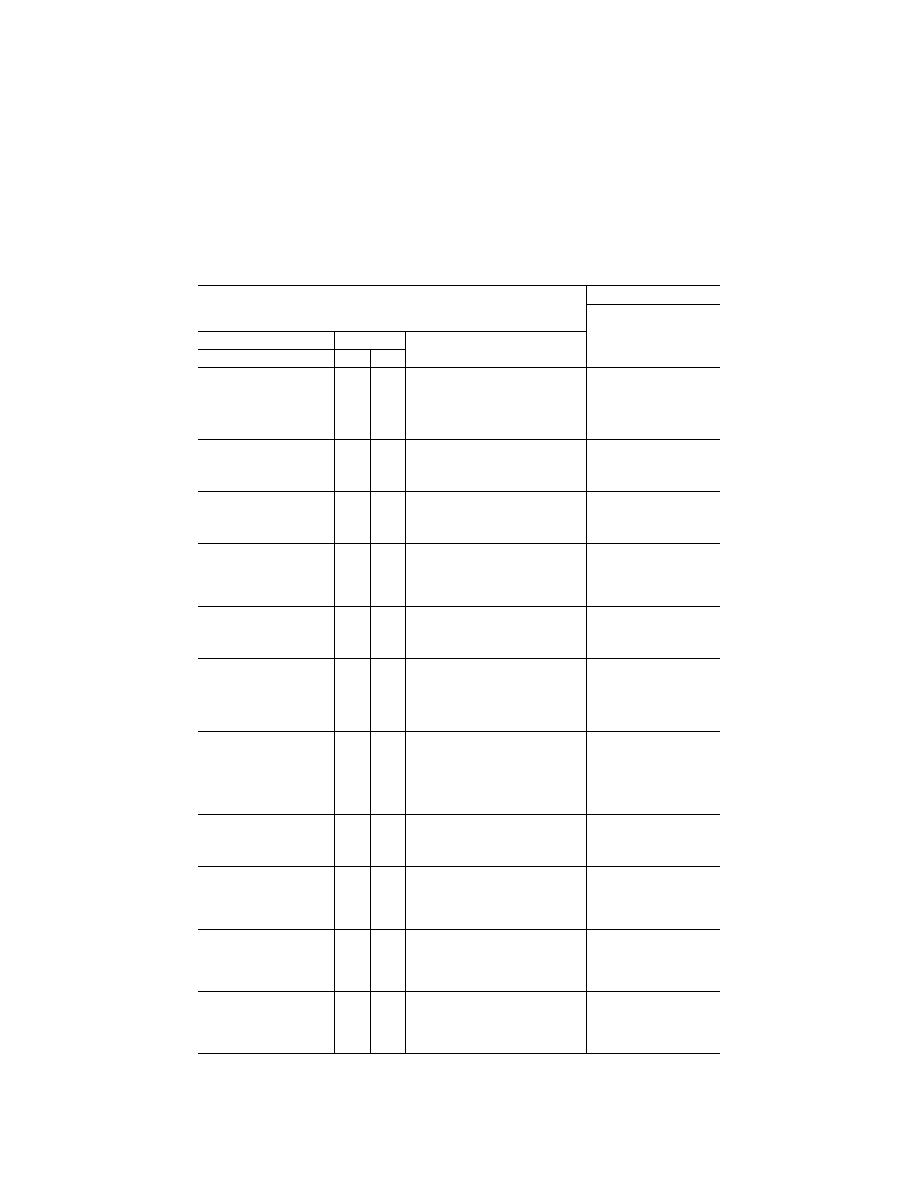

a. This appendix contains background in-

formation as well as regulatory and inform-

ative material as described later in this sec-

tion. To assist the reader in determining

what areas are required and what areas are

permissive, the text in this appendix is di-

vided into two sections: ‘‘QPS Require-

ments’’ and ‘‘Information.’’ The QPS Re-

quirements sections contain details regard-

ing compliance with the part 60 rule lan-

guage. These details are regulatory, but are

found only in this appendix. The Information

sections contain material that is advisory in

nature, and designed to give the user general

information about the regulation.

b. [Reserved]

c. The responsible Flight Standards office

encourages the use of electronic media for

all communication, including any record, re-

port, request, test, or statement required by

this appendix. The electronic media used

must have adequate security provisions and

be acceptable to the responsible Flight

Standards office.

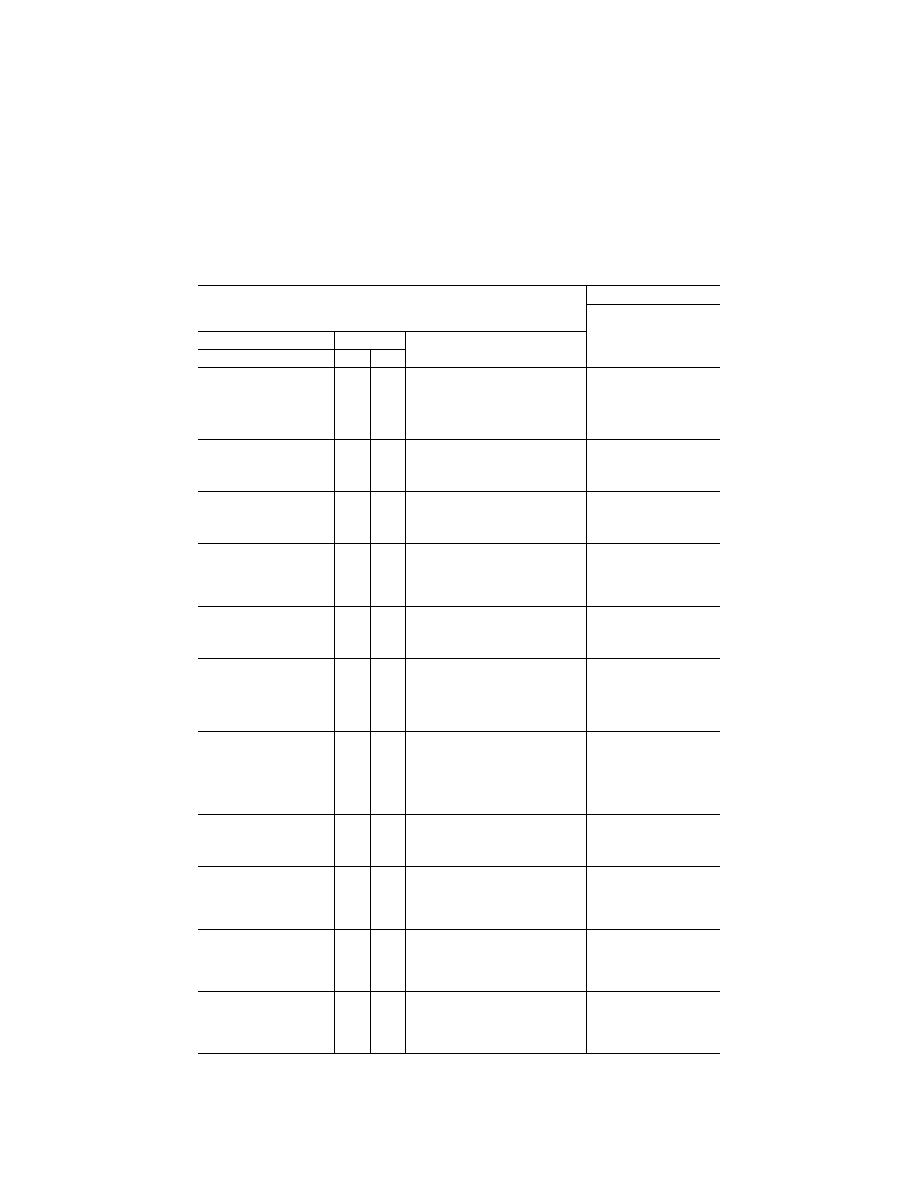

d. Related Reading References.

(1) 14 CFR part 60.

(2) 14 CFR part 61.

(3) 14 CFR part 63.

(4) 14 CFR part 119.

(5) 14 CFR part 121.

(6) 14 CFR part 125.

(7) 14 CFR part 135.

(8) 14 CFR part 141.

(9) 14 CFR part 142.

(10) AC 120–28, as amended, Criteria for Ap-

proval of Category III Landing Weather

Minima.

(11) AC 120–29, as amended, Criteria for Ap-

proving Category I and Category II Landing

Minima for part 121 operators.

(12) AC 120–35, as amended, Flightcrew

Member, Line Operational Simulations:

Line-Oriented Flight Training, Special Pur-

pose Operational Training, Line Operational

Evaluation.

(13) AC 120–40, as amended, Airplane Simu-

lator Qualification.

(14) AC 120–41, as amended, Criteria for

Operational Approval of Airborne Wind

Shear Alerting and Flight Guidance Sys-

tems.

(15) AC 120–57, as amended, Surface Move-

ment Guidance and Control System

(SMGCS).

(16) AC 150/5300–13, as amended, Airport De-

sign.

(17) AC 150/5340–1, as amended, Standards

for Airport Markings.

(18) AC 150/5340–4, as amended, Installation

Details for Runway Centerline Touchdown

Zone Lighting Systems.

(19) AC 150/5340–19, as amended, Taxiway

Centerline Lighting System.

(20) AC 150/5340–24, as amended, Runway

and Taxiway Edge Lighting System.

(21) AC 150/5345–28, as amended, Precision

Approach Path Indicator (PAPI) Systems.

(22) International Air Transport Associa-

tion document, ‘‘Flight Simulation Training

Device Design and Performance Data Re-

quirements,’’ as amended.

(23) AC 25–7, as amended, Flight Test Guide

for Certification of Transport Category Air-

planes.

(24) AC 23–8, as amended, Flight Test Guide

for Certification of Part 23 Airplanes.

(25) International Civil Aviation Organiza-

tion (ICAO) Manual of Criteria for the Quali-

fication of Flight Simulation Training De-

vices, as amended.

(26) Aeroplane Flight Simulation Training

Device Evaluation Handbook, Volume I, as

amended and Volume II, as amended, The

Royal Aeronautical Society, London, UK.

(27) FAA Airman Certification Standards

and Practical Test Standards for Airline

Transport Pilot, Type Ratings, Commercial

Pilot, and Instrument Ratings

(28) The FAA Aeronautical Information

Manual (AIM). An electronic version of the

AIM is on the Internet at

http://www.faa.gov/

atpubs.

(29) Aeronautical Radio, Inc. (ARINC) doc-

ument number 436, titled

Guidelines For Elec-

tronic Qualification Test Guide (as amended).

(30) Aeronautical Radio, Inc. (ARINC) doc-

ument 610,

Guidance for Design and Integra-

tion of Aircraft Avionics Equipment in Simula-

tors (as amended).

E

ND

I

NFORMATION

llllllllllllllllllllllll

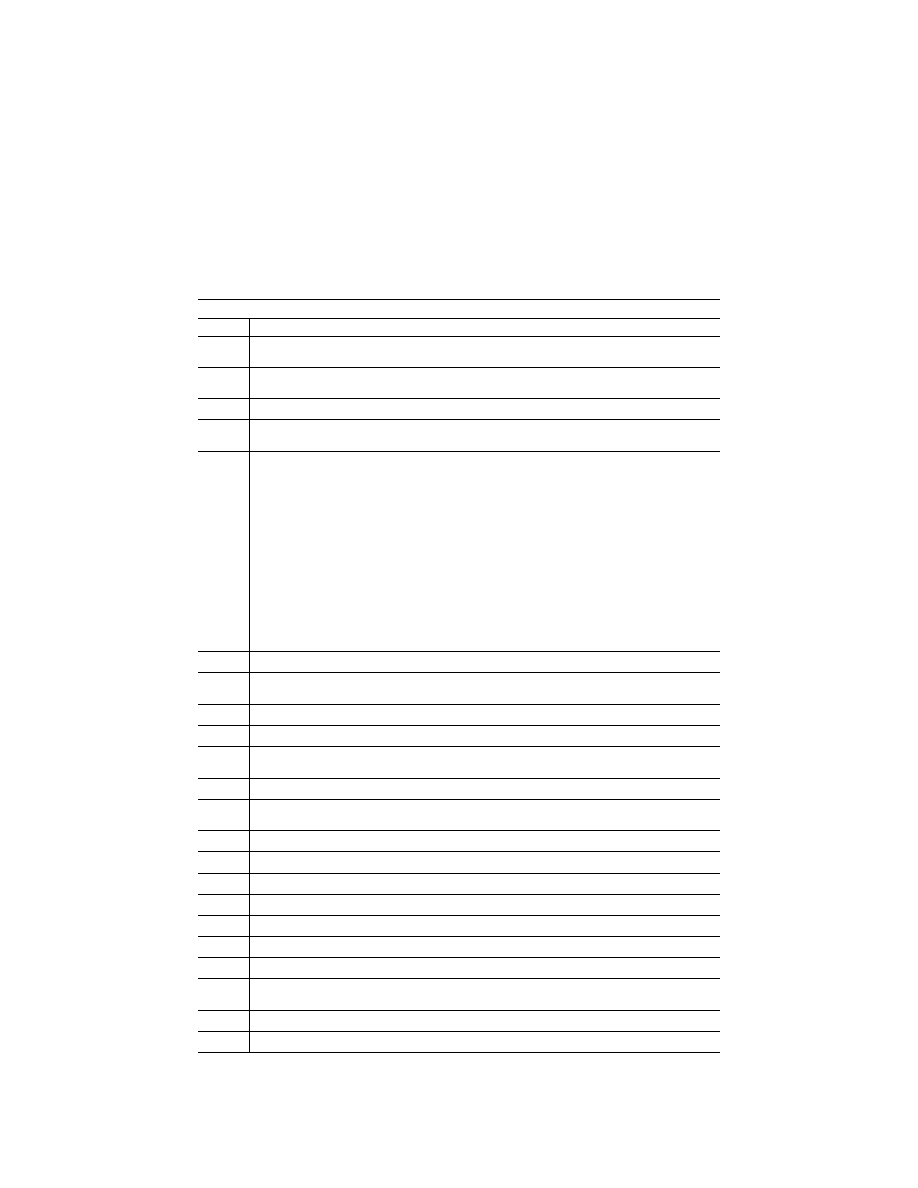

2. A

PPLICABILITY

(§§ 60.1

AND

60.2)

llllllllllllllllllllllll

B

EGIN

I

NFORMATION

No additional regulatory or informational

material applies to § 60.1, Applicability, or to

§ 60.2, Applicability of sponsor rules to per-

sons who are not sponsors and who are en-

gaged in certain unauthorized activities.

E

ND

I

NFORMATION

llllllllllllllllllllllll

3. D

EFINITIONS

(§ 60.3)

llllllllllllllllllllllll

B

EGIN

I

NFORMATION

See Appendix F of this part for a list of

definitions and abbreviations from part 1 and

VerDate Sep<11>2014

14:00 Mar 14, 2024

Jkt 262047

PO 00000

Frm 00029

Fmt 8010

Sfmt 8002

Q:\14\14V2.TXT

PC31

aworley on LAPBH6H6L3 with DISTILLER

20

14 CFR Ch. I (1–1–24 Edition)

Pt. 60, App. A

part 60, including the appropriate appendices

of part 60.

E

ND

I

NFORMATION

llllllllllllllllllllllll

4. Q

UALIFICATION

P

ERFORMANCE

S

TANDARDS

(§ 60.4)

llllllllllllllllllllllll

B

EGIN

I

NFORMATION

No additional regulatory or informational

material applies to § 60.4, Qualification Per-

formance Standards.

E

ND

I

NFORMATION

llllllllllllllllllllllll

5. Q

UALITY

M

ANAGEMENT

S

YSTEM

(§ 60.5)

llllllllllllllllllllllll

B

EGIN

I

NFORMATION

See Appendix E of this part for additional

regulatory and informational material re-

garding Quality Management Systems.

E

ND

I

NFORMATION

llllllllllllllllllllllll

6. S

PONSOR

Q

UALIFICATION

R

EQUIREMENTS

(§ 60.7)

llllllllllllllllllllllll

B

EGIN

I

NFORMATION

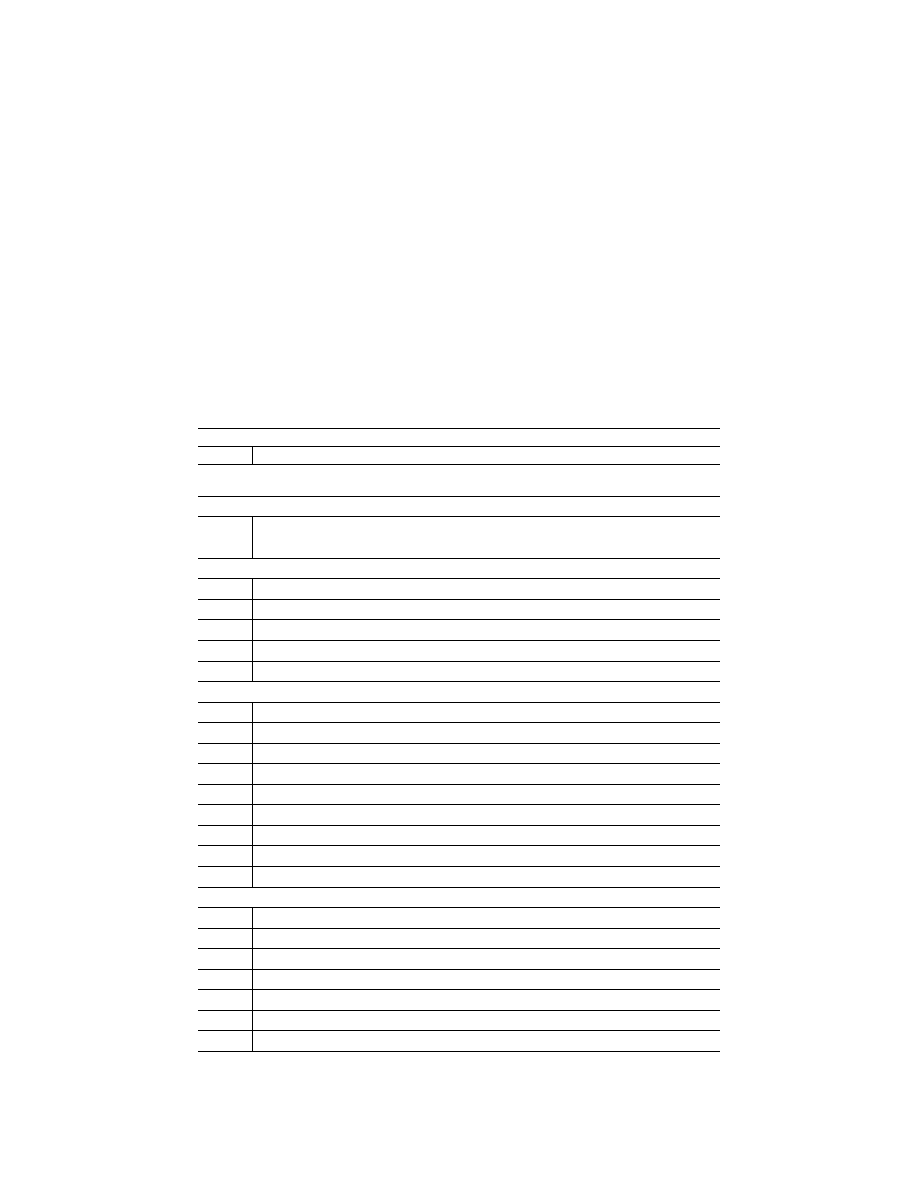

a. The intent of the language in § 60.7(b) is

to have a specific FFS, identified by the

sponsor, used at least once in an FAA-ap-

proved flight training program for the air-

plane simulated during the 12-month period

described. The identification of the specific

FFS may change from one 12-month period

to the next 12-month period as long as the

sponsor sponsors and uses at least one FFS

at least once during the prescribed period.

No minimum number of hours or minimum

FFS periods are required.

b. The following examples describe accept-

able operational practices:

(1) Example One.

(a) A sponsor is sponsoring a single, spe-

cific FFS for its own use, in its own facility

or elsewhere—this single FFS forms the

basis for the sponsorship. The sponsor uses

that FFS at least once in each 12-month pe-

riod in the sponsor’s FAA-approved flight

training program for the airplane simulated.

This 12-month period is established accord-

ing to the following schedule:

(i) If the FFS was qualified prior to May 30,

2008, the 12-month period begins on the date

of the first continuing qualification evalua-

tion conducted in accordance with § 60.19